Manufacturing Process of Tungsten Heater

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 June 2016 10:34

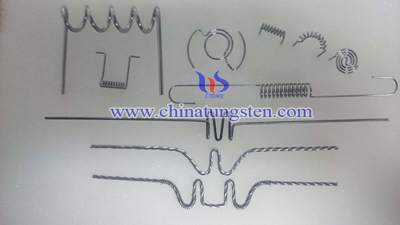

Tungsten heater may also be known as tungsten evaporator coil, which is made by special heat treatment process, and it has a good corrosion resistance and excellent thermostability. It can be used for plastic color plating, optical fiber deposition coating gold or aircraft industry, film, photography, and scientific research. The heart of the vacuum coating process is a tungsten heater as a heating source.

Wolfram heater is generally made of high-temperature multi-strand tungsten wires twisting, hot - forming, cleaning, surface treatment, heat-setting and other processes. Every procedure has to be controlled in strictly technology requirements. The twisting process is to use more than two tungsten wire are interwoven together in accordance with a predetermined direction, in order to ensure that there is a certain cross-section on the electrical properties and a certain degree of flexibility of the mechanical properties. Then use special equipment for the molding pressing. Next is to the cleaning and surface treatment of the heater, making its surface has no visible cracks and the contaminants, such as oxides and drawing lubricants. Contaminants on surface will have an impact in the vacuum content, and play a negative role on the follow-up free metal evaporation rates. The final step is to heat setting process. It is necessary for this process to strictly control the recrystallization temperature of tungsten. Heat setting refers to the use of heat, eliminate the internal stress generated in the fabric fiber drawing process, so that a certain degree of relaxation macromolecules so fixed woven fibers forming the shape. This process is to use heat to eliminate the internal stresses formed by stretching process, slacking macromolecule and finalizing the design of weave fiber. This process can improve the stability of the size of wolfram heater and reduce washing shrinkage. What’s more, it can eliminate wrinkles and improve its crease resistance and the comprehensive performance. When heat setting for wolfram heater, it should not be processing in a high temperature, avoiding surface oxidation.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com