Hexagonal Tungsten Bronze Rod Nano Particles and Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 06 June 2016 17:47

With the social development and productivity improvements, demand for energy is growing, due to the energy consumption process will produce a lot of smoke and harmful gas pollution, caused by a variety of environmental problems such as greenhouse effect, acid rain is also a growing concern of the whole society. Thus, energy saving is the sustainable economic development of countries must be considered. Solar spectrum in the near-infrared light about 46% of energy consumption in many countries, the building energy consumption accounts for about 30 to 40% of national energy consumption, and energy consumption through the glass doors and accounted for 50% of building energy consumption the above. Building energy-saving insulation glazing for energy conservation is important.

Thus, the development of thermal insulation coatings, paint and building insulation especially closely related to human life has great practical significance. Predictable, transparent insulation coating, transparent insulation film due to economic, easy to use and good thermal insulation and other advantages and bright prospects.

Currently on the market several common transparent insulation particles due to its excellent transparency, heat insulation performance, has received wide attention. However, most transparent insulation particles there are various deficiencies, such as: silver multilayer film is not stable in the air, and the need to use expensive sputtering made of a multilayer film, resulting in High its price; antimony tin oxide (ATO) and indium tin oxide (ITO) in the near infrared range of small shelter, shielding their poor; and LaB6 not absorb near-infrared waveband, also absorbs the visible range of the electromagnetic waves, resulting in the insulation film too deep color, transparency, etc. greatly reduced. Thus, the industry needed a new type of transparent insulation material, the transparent insulation material should have a low cost, high visible light transmittance, high thermal insulation properties and high stability.

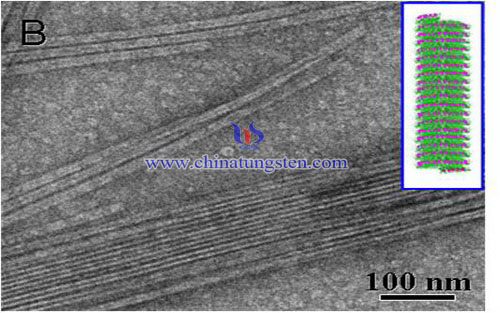

A method for preparing a hexagonal tungsten bronze rod nano particles, the steps:

1. Through exchange resin - sol-gel method or rapid acidification Preparation of solid colloidal tungstic acid; wherein: exchange resin sol - gel method comprises the following steps: (1) tungstate dissolved in water to obtain a concentration of tungstate solution 0.1~2mol / L of; (2) the use of cation exchange resin tungstate solution into acid solution; (3) the acid solution was allowed to stand in 0~100 ° C under aging 0.01~48h make gel to give a gum solid acid. The rapid acidification method comprises the following steps: (1) tungstate dissolved in water to obtain a concentration 0.01~5mo 1 / L of the tungstate solution; (2) under agitation excess acid solution was quickly added to the tungstate solution to PH <1; said acidic solution is a lactic acid, tartaric acid, acetic acid, oxalic acid, hydrochloric acid, sulfuric acid, nitric acid, citric acid or a mixed solution, the concentration 0.1~18.4mol / L; (3) continuously subjected to suction filtration after stirring colloidal floc formation resulting solid suspension tungstate gum acid. Tungstates described as: sodium tungstate, potassium tungstate, lithium tungstate, cesium, calcium tungstate, tungsten, bismuth, tungsten acid, silver, tungsten, zinc, magnesium and tungsten, partial ammonium tungstate, ammonium tungstate positive, ammonium paratungstate, alkali metal tungstate one or a mixture thereof.

1. Through exchange resin - sol-gel method or rapid acidification Preparation of solid colloidal tungstic acid; wherein: exchange resin sol - gel method comprises the following steps: (1) tungstate dissolved in water to obtain a concentration of tungstate solution 0.1~2mol / L of; (2) the use of cation exchange resin tungstate solution into acid solution; (3) the acid solution was allowed to stand in 0~100 ° C under aging 0.01~48h make gel to give a gum solid acid. The rapid acidification method comprises the following steps: (1) tungstate dissolved in water to obtain a concentration 0.01~5mo 1 / L of the tungstate solution; (2) under agitation excess acid solution was quickly added to the tungstate solution to PH <1; said acidic solution is a lactic acid, tartaric acid, acetic acid, oxalic acid, hydrochloric acid, sulfuric acid, nitric acid, citric acid or a mixed solution, the concentration 0.1~18.4mol / L; (3) continuously subjected to suction filtration after stirring colloidal floc formation resulting solid suspension tungstate gum acid. Tungstates described as: sodium tungstate, potassium tungstate, lithium tungstate, cesium, calcium tungstate, tungsten, bismuth, tungsten acid, silver, tungsten, zinc, magnesium and tungsten, partial ammonium tungstate, ammonium tungstate positive, ammonium paratungstate, alkali metal tungstate one or a mixture thereof.

2. Reaction of the precursor solution: select the appropriate solvent and inducing agent, formulated M-containing salt and solid colloidal tungsten acid precursor solution, the precursor solution M: W atomic molar ratio (0.1~1): 1, wherein the solid acid gel mom its concentration in the reaction liquid precursor is 0.001~5mol / L; inducer precursor molar concentration in the reaction mixture is 0.1~5.0mol / L. The specific process: Weigh M salt and inducing agent, which is dissolved in a solvent, under stirring conditions by means of the resin in step 1 after mixing exchange - gummy solid acid sol - gel method obtained after minced added thereto, and stirring was continued 1~5h, to obtain a reaction precursor solution; or, in the step 1 by solid acid gel prepared by rapid acidification of the rule of law dispersed in a solvent, and then at successively added thereto with stirring M salt, the solvent, and inducing stir thoroughly mixed to obtain a liquid reaction precursor. The solvent is water, acetone, benzene, toluene, xylene, amyl , hexane, octane, cyclohexane, cyclohexanone, chlorobenzene, dichlorobenzene, dichloromethane, methanol, ethanol, propanol, butanol, isopropanol, diethyl ether, acetic acid, propylene oxide, acetate methyl acetate, ethyl acetate, propyl acetate, acetyl acetone, methyl ethyl ketone, methyl isobutyl ketone, ethylene glycol monomethyl ether, ethylene glycol monomethyl ether, ethylene glycol mono-butyl ether, acetonitrile, pyridine, phenol one or mixtures thereof. The inducing agent is oxalic acid, formic acid, tartaric acid, acetic acid, lactic acid, ethanol, citric acid, ascorbic acid, sorbitol, diethylene glycol, triethylene glycol, tetraethylene glycol, polyethylene glycol, , sorbic acid, polyethylene glycol, potassium borohydride, sodium borohydride, aniline, acetyl acetone, N2H4.H2O .

3. Synthetic powder, washing and drying dry: the step 2 was prepared in the reaction precursor reaction 5~72 hours at 90~400 ° C, the precipitate was successively washed with water after the reaction, an alcohol wash, after centrifugation at 50~80 ° C under bake get MxWO3 dry powder.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com