Electrolysis method for preparing tungsten trioxide powder

- Details

- Category: Tungsten Information

- Published on Friday, 25 December 2015 16:19

Tungsten has a high melting point, vapor pressure, high hardness, corrosion resistance and good acid excellent physical and chemical properties, for use in various sectors of the national economy and defense industry range and consumption is increasing year by year. However, tungsten is an important national strategic non-renewable resources, although tungsten ore resources to maintain our country ranks first in the world, but to deal with the preparation of tungsten concentrate tungsten metal powder to go through the decomposition of tungsten concentrate, APT system to take three Preparation of tungsten oxide and reducing tungsten powder preparation process, there is a long production process and other shortcomings, the development of short process, improve resource utilization, reduce production costs has become a trend in metallurgical technology development.

Molten salt electrolysis

Molten salt electrolysis method is one method of producing metal from theory, most of the metal is obtained by the molten salt electrolysis process, especially for those who can not generate more negative deposition potential of metal ions in an aqueous solution, must melt salt electrolysis. Currently, aluminum, and some rare earth metals by molten salt electrolysis production. Given the molten salt electrolysis method for the preparation of metals and their alloys aspects of the unique advantages and potential of certain alkali metals, alkaline earth metals (such as Li, Na, Mg), almost all of the transition metal elements and rare earth elements, and some rare high melting point metal such as Ti, Sc, Nab, Ta, has become with molten salt electrolysis producing metal hotspot. In addition, studies using molten salt electrolysis method also involves some non-metallic elements such as B, Si and the like. With the success of the preparation of a number of elemental metals, molten salt electrolysis research in the field of preparation of the alloy is also very wide, including aluminum alloy (such as Al-k, Al-Sr like), magnesium alloys, titanium alloys and rare earth alloy.

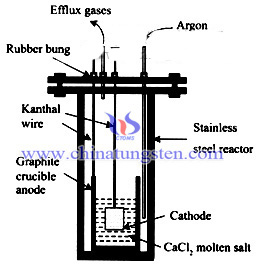

The experiment comprises the following steps: (1) mixing molten salt and water removal (2) treatment electrode (3) pre-electrolyzed (4) electrolysis (main parameters: temperature, cell voltage, current density and electrolysis time, etc.) (5) Tungsten powder separation and collection. Preparation of raw material of the present invention is a low cost, short process, simple equipment, there is no solid, liquid and gas waste emissions, no secondary pollution, at low cost direct electrolysis of tungsten powder prepared from tungstate.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com