Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅶ

- Details

- Category: Tungsten Information

- Published on Monday, 23 November 2015 11:50

In last part we know that as the main tool failure mode, flank wear of (Al,Cr)N coated tungsten carbide tool is slower than the (Ti,Al)N coated one. And this part we will get to understand of the wear mechanism of the two coating films on tungsten carbide tools.

Fig. 3 shows the SEM observation and EDS mapping analysis on the worn surface of the (Ti,Al)N coated tungsten carbide tool and the (Al, Cr)N coated tool. Fig.3 (a) shows the details of “A”shown in Fig. 1. Fig. 3 (b) shows the EDS analysis in the case of the oxygen (O) mapping on the cutting part shown in Fig. 1.

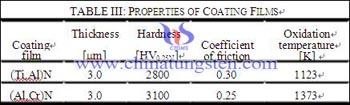

First, as compared with the worn surface of (Ti,Al)N coating film indicated by “B” shown in Fig. 3 i(a) and that of(Al,Cr)N coating film indicated by “B” shown in Fig. 3 ii(a), many striae scratched by a hard material are remarkably found on the worn surface in the case of both the (Ti,Al)N and the (Al,Cr)N coating film. Therefore, the main wear mechanism of both the (Ti,Al)N and the (Al,Cr)N coating film is considered to be abrasive wear. In the case of abrasive wear, the wear-resistance of the coating film often depends on the hardness of the coating film. That is, a coating film with higher hardness has good wear-resistance. So the characteristics of the coating films were investigated. The results are shown in Table III. The thickness of coating of (Al,Cr)N film is 3 μm, which is the same as that of (Ti,Al)N film. The (Al,Cr)N coating is harder than the (Ti,Al)N coating because the wear progress of (Al,Cr)N is considered to be slower than that of (Ti,Al)N.

(To be continued. This article is divided into several parts. Here is part 7 For part 6 please refer to http://news.chinatungsten.com/en/tungsten-information/80627-ti-10436; for part 8 please refer to http://news.chinatungsten.com/en/tungsten-information/80629-ti-10438)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com