Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅵ

- Details

- Category: Tungsten Information

- Published on Monday, 23 November 2015 11:46

In last part we know that after testing, tungsten carbide tools with (Al,Cr)N coating film exhibit much better wear resistance quality than with (Ti,Al)N coating. In this part we will get to a closer analysis of the flank wear feature of the two coated tungsten carbide tools.

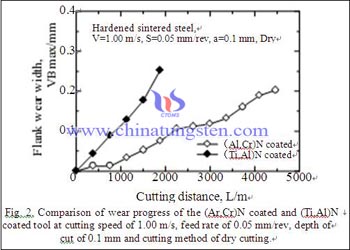

Following these experiments, it emerged that the main tool failure for two kinds of coated tools in cutting hardened sintered steel was the flank wear within a maximum value of the flank wear width of about 0.2 mm. Therefore, the maximum value of the flank wear width (VBmax) was measured by microscope.

Fig. 2 shows the wear progress in cutting two kinds of coated tools at a cutting speed of 1.00 m/s. The wear progress of the (Al,Cr)N coated tool is slower than that of the (Ti,Al)N coated tool. As mentioned above, the (Al,Cr)N coated cemented tungsten carbide tool is an effective tool material in cutting hardened sintered steel, so Scanning Electron Microscopy (SEM) observation and Energy Dispersive X-ray Spectrometer (EDS) analysis were carried out on the worn surface.

(To be continued. This article is divided into several parts. Here is part 6. For part 5, please refer to http://news.chinatungsten.com/en/tungsten-information/80617-ti-10434; for part 7, please refer to http://news.chinatungsten.com/en/tungsten-information/80628-ti-10437)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com