Properties of Tungsten Mine Waste Geopolymeric Binder- Experimental Work II

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 August 2015 16:46

Properties of tungsten mine waste geopolymeric binder

Experimental work

Materials

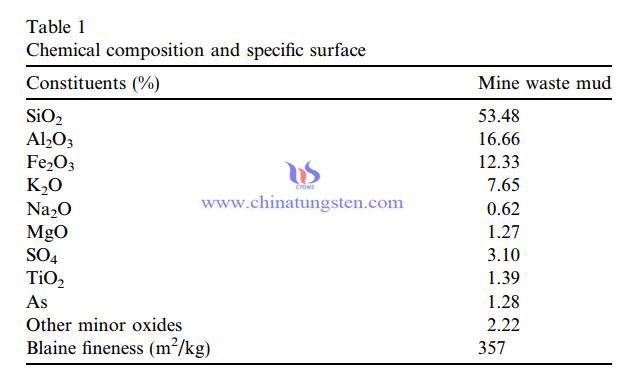

The chemical composition and specific surface of the calcined mine waste mud is shown in Table 1. The figures clearly show that mine waste mud consists essentially of silica and alumina, contaminated with arsenic and sulphur and with a high content of iron and potassium oxide. Although it’s known that iron oxide contributes to the strength of Portland cement it is still and open question if iron also contributes to geopolymerization. The SiO2/ Al2O3 atomic ratio is 5.5 higher than the one suggested by Davidovits of about 2 for making cement and concrete however, the final SiO2/Al2O3 atomic ratio in the hardened binder depends mainly on the reactivity of Al–Si because not all the silica and alumina are reactive so one can not expect the same Si/Al ratio in the final hydration product as the one present in the original precursor material. Indeed most of the Al–Si materials cannot even supply suf- ficient Si in alkaline solution to start geopolymerization, this explains why they need extra silica provided in solution by waterglass, which influences the Si/Al ratio of the hardened binder.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com