Response Characteristics of Barium Tungsten Electrode in High-Frequency Pulse Discharge

- Details

- Category: Tungsten Information

- Published on Monday, 09 June 2025 19:27

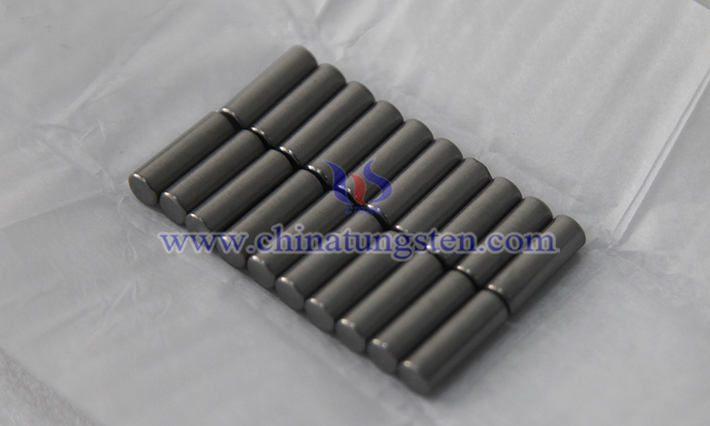

Barium tungsten electrode shows fast response, high emission efficiency and good stability in high-frequency pulse discharge. Its performance depends on low-work-function barium-based materials, optimized porous tungsten matrix and fine preparation process.

1. Material Composition and Electron Emission Performance

Barium tungsten electrode is based on tungsten, doped with low-work-function barium or its compounds to reduce the electron emission energy, significantly improving the response speed and efficiency of pulse discharge. The barium content needs to be precisely controlled. Too high will cause barium volatilization at high temperature and shorten the electrode life; too low will result in insufficient emission performance.

2. Microstructure and Porosity

The porous tungsten matrix structure of barium tungsten electrode is crucial to high-frequency pulse response. Uniform pore size distribution and good internal pore connectivity (such as preparation with spherical tungsten powder) can increase the slope of the space charge confinement region, thereby improving emission uniformity and current density. Narrow particle size tungsten powder combined with spark plasma sintering technology can reduce closed-cell defects and further optimize conductivity and mechanical strength.

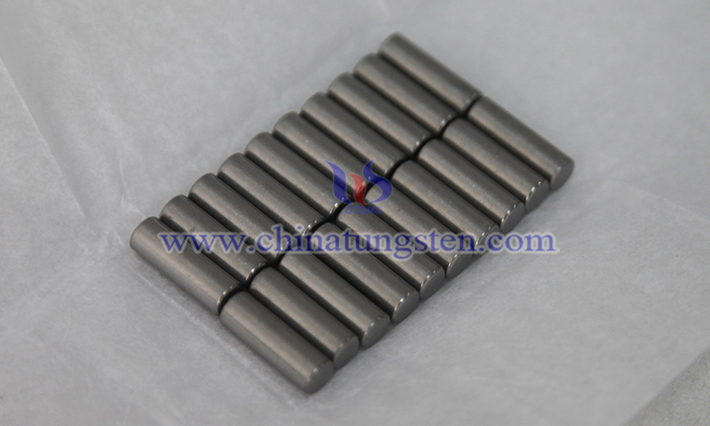

3. Preparation Process

The impregnation process ensures uniform distribution of active materials and avoids pore blockage, thereby ensuring continuous diffusion of barium ions and stable electron emission under high-frequency pulses. The spherical tungsten powder matrix prepared by radio frequency plasma spheroidization technology can further improve the smoothness of the pore channel and emission efficiency.

4. Response Characteristics in High-Frequency Pulse Discharge

Fast Response: Due to its low work function and optimized matrix structure, the barium tungsten electrode can ignite quickly under high-frequency pulses (MHz level), reduce the ignition voltage, and improve the luminous efficiency.

Stability: The selection of high-stability emission materials such as barium aluminate, combined with activators, can ensure the continuous release of barium ions during long-term use and maintain discharge stability.

Life and Volatilization: The high temperature of high-frequency pulses will cause barium volatilization, and the electrode life needs to be extended by optimizing the barium content and matrix porosity.

Uniformity: Uniform material composition and pore distribution reduce local performance fluctuations and ensure the uniformity and reliability of discharge under high-frequency pulses.

5. Impact of Working Environment

High-frequency pulse discharge is often used in high-intensity gas discharge lamps or pulse power sources, requiring electrodes to adapt to harsh environments such as high vacuum and wide temperature range. Impurity contamination (such as moisture in the air) will reduce the performance of barium active substances, so they need to be sealed or stored using stable materials.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com