Military Tungsten Alloy Cube for Type 092 Submarine

- Details

- Category: Tungsten Information

- Published on Friday, 18 October 2013 10:09

- Hits: 1467

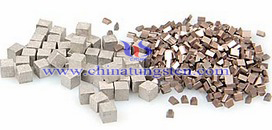

Military tungsten alloy cube is usually consisted of W-Ni- Fe or W-Ni- Cu or even W-Ni-Cu-Fe. The most important property for tungsten alloy cube is that small volume with high density, which means it can be used as counterweight for Type 092 submarine.

Type 092 submarine was the first ballistic missile-carrying, nuclear-powered submarine class (SSBN) deployed by the Chinese People's Liberation Army Navy, and the first SSBN designed and built in Asia. She was designed by Peng Shilu and Huang Xuhua, and derived from the Han-Class SSNs, with an extended hull to accommodate twelve missile tubes.

Using military tungsten alloy cube, Type 092 submarine reaches to a definite magnitude so that can relize immersion.

Compared with lead, the density of military tungsten alloy cube is higher but value is smaller. Otherwise, military tungsten alloy cube is nontoxic. So military tungsten alloy cube is ideal counterweight for Type 092 submarine.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military Tungsten Alloy Cube for Triomphant-class Submarine

- Details

- Category: Tungsten Information

- Published on Friday, 18 October 2013 09:56

- Hits: 1517

Military tungsten alloy cube is usually consisted of W-Ni- Fe or W-Ni- Cu or even W-Ni-Cu-Fe. The most important property for tungsten alloy cube is that small volume with high density, which means it can be used as counterweight for Triomphant-class submarine.

Triomphant-class submarine of the French Navy is the active class of four boats that entered service in 1997, 1999, 2004, and 2010. These four supersede the older Redoutable-class, and they provide the ocean-based component of France's nuclear deterrent strike force, the Force de Frappe.

Using military tungsten alloy cube, Triomphant-class submarine reaches to a definite magnitude so that can relize immersion.

Compared with lead, the density of military tungsten alloy cube is higher but value is smaller. Otherwise, military tungsten alloy cube is nontoxic. So military tungsten alloy cube is ideal counterweight for Triomphant-class submarine.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military Tungsten Alloy Cube for Submarine

- Details

- Category: Tungsten Information

- Published on Friday, 18 October 2013 09:35

- Hits: 1279

Military tungsten alloy cube is usually consisted of W-Ni- Fe or W-Ni- Cu or even W-Ni-Cu-Fe. The most important property for tungsten alloy cube is that small volume with high density, which means it can be used as counterweight for submarine.

Submarine is a watercraft capable of independent operation underwater. It differs from a submersible, which has more limited underwater capability. The term most commonly refers to a large, crewed, autonomous vessel. It is also sometimes used historically or colloquially to refer to remotely operated vehicles and robots, as well as medium-sized or smaller vessels, such as the midget submarine and the wet sub.

Using military tungsten alloy cube, submarine reaches to a definite magnitude so that can relize immersion.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military Tungsten Alloy Cube for Ballistic Missile submarine

- Details

- Category: Tungsten Information

- Published on Friday, 18 October 2013 09:44

- Hits: 1336

Military tungsten alloy cube is usually consisted of W-Ni- Fe or W-Ni- Cu or even W-Ni-Cu-Fe. The most important property for tungsten alloy cube is that small volume with high density, which means it can be used as counterweight for ballistic missile submarine.

Ballistic missile submarine is a submarine equipped to launch submarine-launched ballistic missiles (SLBMs) with nuclear warheads. In the US Navy they have the designation SSBN and they are nicknamed 'boomers', a common term of art used in everyday briefings and base operations. Virtually all ballistic missile submarines are nuclear powered and are therefore nuclear submarines.

Using military tungsten alloy cube, ballistic missile submarine reaches to a definite magnitude so that can relize immersion.

Military tungsten alloy has high density but small value, so it is quir suitable for ballistic missile submarine.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

What Is the Difference Between Gold-filled and Gold-plated?

- Details

- Category: Tungsten Information

- Published on Friday, 18 October 2013 08:51

- Written by Cher

- Hits: 1622

When purchasing gold jewelry, less costly options exist that give the look of gold without the hefty price. Gold-plated and gold-filled jewelry are two options that feature a base metal and a layer of gold, which gives the appearance of gold but not the price tag.

Gold-filled Jewelry

Gold-filled jewelry uses a technique in which thin layers of gold are bonded by heat and pressure to a brass center. Several layers of a core metal are surrounded by at least 10k gold. Jewelers usually note the ratio of gold to base metals. United States requirements state that gold-filled jewelry must contain no less than 1/20 its weight in gold.

Gold-plated Jewelry

Gold-plated jewelry has a thin molecule of gold overlaying a base metal such as zinc, copper or nickel. This thin layer is not 14k and usually wears off the base within a short period of time. Jewelry makers utilize an electrochemical process to bind the thin layer of gold to the base metal. Gold-plated jewelry may contain varying thicknesses of gold.

Pros and Cons of Gold-filled Jewelry

Gold-filled jewelry lasts much longer than gold-plated jewelry. The gold used is at least 10k gold, unlike gold-plated jewelry, which contains less than 10k gold. The bonding process and layers make the jewelry more durable. If you plan to wear a jewelry piece frequently, you should choose gold-filled over gold-plated. The only drawback is that gold-filled jewelry will be more costly initially.

Pros and Cons of Gold-plated Jewelry

The thin layer of gold-plated jewelry is soft and easily scratched. Therefore, jewelers such as Gem Fashion do not recommend wearing gold-plated jewelry on a frequent basis. Skin oils and the environment eventually wear off the gold layer. However, gold-plated jewelry is less expensive than gold-filled jewelry.

History

Gold jewelry has been popular since the days of ancient Egypt and Greece. Rolled or filled gold experienced popularity during the Victorian era because the gold-filled jewelry was more affordable for the middle class. During the Edwardian era, the popularity of smaller pieces made gold-filled jewelry less popular. A resurgence in popularity occurred during the Retro or Retro Modern period of the 1930s. When the U.S. Department of Commerce began restricting gold-filled jewelry to jewelry with at least 20 percent gold, gold-plated jewelry gained popularity.

Gold plated Tungsten Product Manufacturer & Supplier: Chinatungsten Online - http://paper-weight.cn/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com