Testing Method of Sag of Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 February 2021 10:43

- Hits: 1675

The testing method of sag of tungsten wire is processed according to Chinese standard of GB 4105-83, which is suitable for the diameter of Ø0.35~1mm.

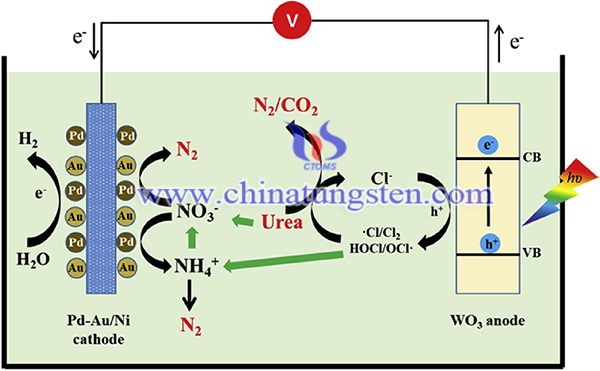

WO3 Photoanode Fabricated with Ammonium Paratungstate for Photoelectric Removal of Urine

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2021 20:35

- Hits: 1778

Urine is one of the most gravimetric nitrogen (N) carriers in human excrement and contributes 80% of the nitrogen and 10% of the COD load in urban sewage in spite of accounting for only one percent of domestic wastewater.

Y2O3 Dispersion Strengthened Tungsten Prepared via APT for The Application of Plasma Facing Materials (PFMs)

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2021 20:30

- Hits: 1659

Fusion power is considered as a promising candidate for future sustainable sources of energy. A major challenge for future fusion devices is the development of plasma facing materials (PFMs). The PFMs should be able to resist the harsh environment of fusion plasmas, e.g., high thermal loads, neutron irradiation, particle fluxes, etc. Therefore, the materials that could be used for PFMs are very limited. Tungsten is a very promising candidate for PFMs due to its high melting point, high temperature strength, good thermal conductivity, low erosion in fusion radiation environment, and low tritium retention.

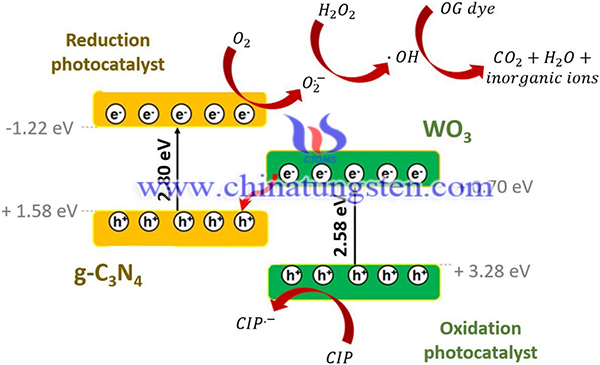

Excellent and Stable WO3 Based Photocatalyst From Ammonium Paratungstate for Degradation of Orange G Dye

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2021 20:11

- Hits: 1668

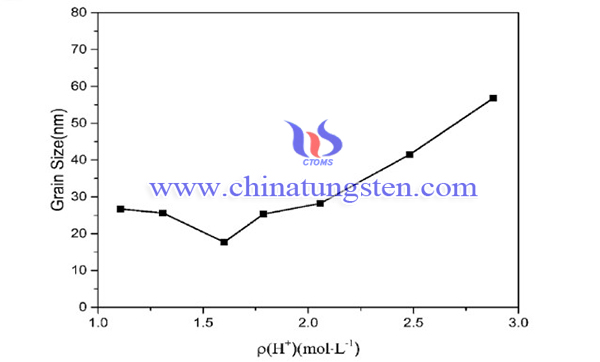

Preparation of W-Y2O3 Nano Composite via APT and the Effect of Hydrogen Ion Concentration

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2021 19:58

- Hits: 1617

Tungsten-based materials are widely used in various field for their unique properties such as high melting points, tensile and creep strength, corrosion and wear resistance, electrical and thermal conductivity. W-Y2O3 nano composite powders were synthesized by wet chemical route using APT as raw materials. The hydrogen ion concentration (ρ(H+)) was controlled to investigate its effect on the grain size and morphology of W-Y2O3 nano composite powders.

Tungsten Trioxide Nanorod Array from Ammonium Paratungstate for Photocatalytic Application

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2021 19:46

- Hits: 1525

The ever-increasing energy demand in the world and the negative environmental impact of fossil fuels has made the development of renewable fuels a priority in science and engineering research. Photoelectrochemical (PEC) water splitting is considered a promising method to produce hydrogen using water as raw material.

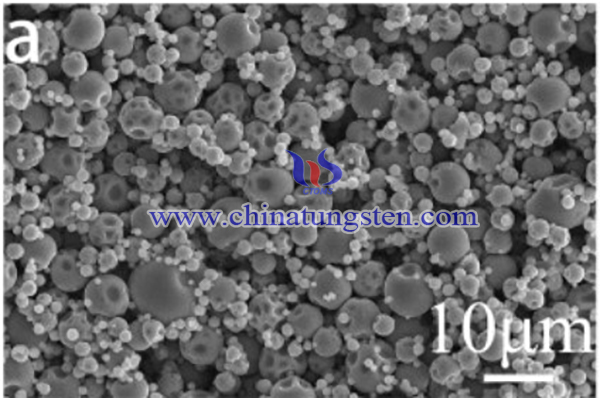

Micro-Spherical Tungsten-Molybdenum Alloy Particles Using APT by Spray Drying

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2021 18:42

- Hits: 1610

Tungsten‑molybdenum (W-Mo) alloy is of considerable interest in recent years as a high temperature material for a various of applications, ranging from electric, electronic, nuclear reactor to space vehicle, due to its outstanding properties including high melting point, low thermal expansion, high thermal conductivity, and excellent mechanical strength at elevated temperature, etc.

Tungsten-Titanium Carbide Composite Prepared Using Ammonium Paratungstate by Wet-Chemical Method

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2021 18:34

- Hits: 1604

Fusion energy has become the most promising clean energy due to its rich raw materials and environment-friendly. In order to product controllable fusion energy, the research of plasma-facing materials (PFMs) is the key issue. W is considered as PFMs due to its excellent properties, such as high melting point, high thermal conductivity, and low tritium retention.

Excellent Tungsten Trioxide Based Photocatalyst with Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2021 18:25

- Hits: 1612

Up to date, titanium dioxide (TiO2) is accepted as the most feasible material for photodegradation of organic and inorganic pollutants. However, the fast recombination of the photocatalytically generated charge carriers competes with the electron transfer of the reactants adsorbed on the catalyst surface, which limits its photocatalysis activity.

WO3/MWCNT Nano Composite by Acid Precipitation via Ammonium Paratungstate for Gas Sensing Application

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2021 18:15

- Hits: 1462

Nanostructured materials are of interest for many researchers as one of promising building blocks for many applications, such as gas sensing, photovoltaic cell and catalysis because of their large surface-to-volume ratio and the nanosize effect. Recently, there is increasing number of research teams exploring various means for synthesis and application of many nanostructured materials, such as titanium dioxide (TiO2), zinc oxide (ZnO), tungsten oxide (WO3), carbon nanotubes (CNTs), graphene, and so on.

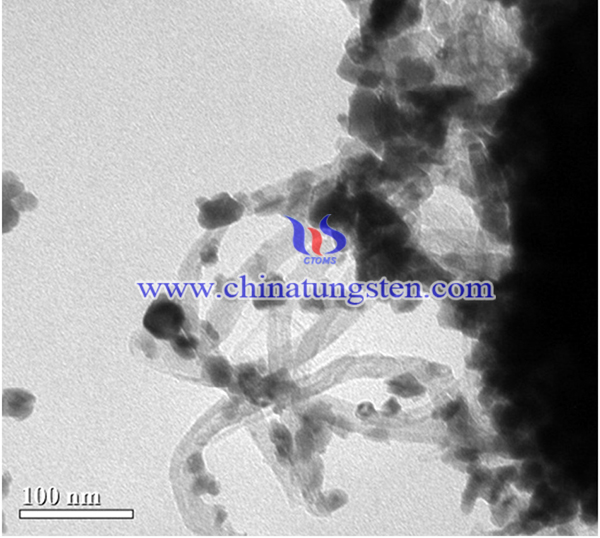

A feasible preparation method WO3/MWCNT nano composite by acid precipitation via ammonium paratungstate (APT) had been conducted for gas sensing application.

The synthesis procedure of WO3/MWCNT nanosized composite is as follows:

Ammonium paratungstate (APT), nitric acid (HNO3), and Multi-walled carbon nanotubes (MWCNTs, Baytubes®) were used as precursor materials. The inner and outer diameters of MWCNTs were 4 and 13 nm, respectively.

Firstly, 300 mL of APT and 0.045 g MWCNTs was heated in a flask at 80 °C. Then 50 mL of 4.5 M of nitric acid was added dropwise to accommodate hydrolysis reaction of tungstate salt. The mixed solution was kept under stirring and refluxing condition for 30 min to ensure the completion of hydrolysis. Then the solution was cooled to room temperature naturally and kept quiescently for one day. The prepared product was washed with de-ionized water and filtrated through nylon membrane with diameter of 0.45 μm until pH of the washed effluent equal to 7 and dried in oven at 100 °C overnight. The as-prepared particulate product was calcined under air atmosphere with various target temperature of 300–600 °C with a holding time of 1–5 h. Finally, the WO3/MWCNT nano materials was produced was filtrated and dried in a hot-air oven before calcined at a designated temperature of 400 °C for 3 h to prevent losing of MWCNTs from combustion.

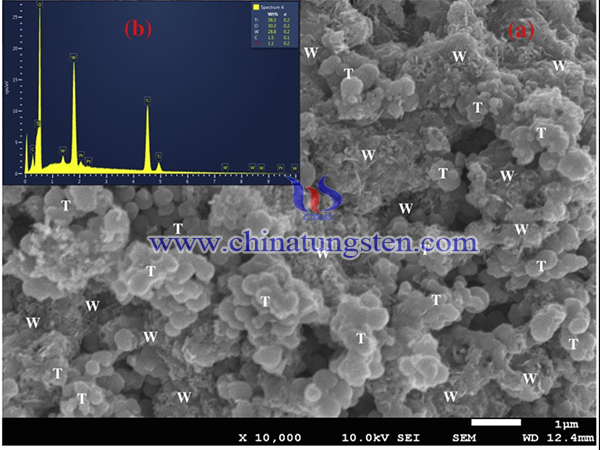

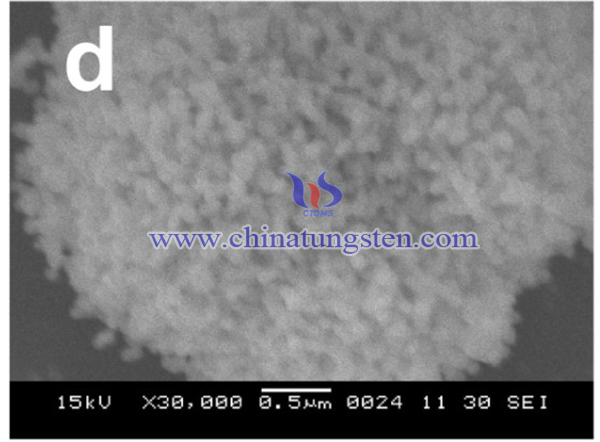

The synthesized WO3 nanoparticles and WO3/MWCNT hybrid materials were analyzed by scanning electron microscope (SEM), transmission electron microscope (TEM) to demonstrate morphology. Crystal structure was studied using an X-ray diffraction technique.

In conclusion, WO3/MWCNT nano composite materials has been produced using APT and MWCNTs. The optimal calcination temperature which could provide WO3/MWCNT hybrid material with uniform dispersion of WO3 on the MWCNT surface would be 400 °C. Regarding to the mesoporosity and the BET surface area of 15.6 m2/g with average pore size of 9.2 nm, the fabricated WO3/MWCNT hybrid material would exhibit potential for gas sensing applications.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com