Low-grade Tungsten Treatment Process and Equipment

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 December 2019 17:27

- Hits: 1862

The low-grade tungsten concentrate produced by some tungsten concentrators can not meet the quality standard, the grade of WO3 is 5-30%, and the content of other impurities is also relatively high. It is mainly low-grade tungsten slime concentrate, tungsten tin medium ore, tungsten bearing iron sand and other refractory tungsten containing intermediate products. These products are sold in the form of sodium tungstate or scheelite, ammonium paratungstate, tungstic acid or tungsten trioxide through chemical beneficiation, and other useful components are comprehensively recovered from the leaching slag. The principle process of chemical beneficiation of low-grade tungsten mineral raw materials can be divided into material preparation, etc.

High Purity Ammonium Metatungstate Crystal Preparation by Nanofiltration

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 December 2019 17:16

- Hits: 2162

With the rapid development of petroleum processing industry, the research and development of tungsten catalysts have been paid more and more attention. The active component of the catalyst, tungsten trioxide, is used as catalyst carrier, such as spherical silicon and aluminum oxide, which are made by leaching and pyrolysis of ammonium metatungstate. This is the direct driving force to promote the development of AMT in recent years. There are many processes for AMT production. Nanofiltration technology is a membrane separation technology separated from reverse osmosis technology, which is the continuation and development branch of ultra-low pressure reverse osmosis technology.

Ammonium Paratungstate Process Introduction and Market Overview

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 December 2019 17:10

- Hits: 1892

Ammonium paratungstate is the main raw material of tungsten industry. In a sense, it is a kind of purified tungsten concentrate, that is to say, the tungsten concentrate containing 60% bustard is purified to the intermediate products containing more than 88.5% tungsten oxide. In the final application products of tungsten, more than 70% are made of apt as the main raw material, while the rest are made of ferrotungsten, metatungsten, tungstic acid and waste tungsten.

Tungsten Trioxide Preparation by Microwave Calcination of Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Monday, 23 December 2019 23:24

- Hits: 1757

Tungsten trioxide is an important intermediate product in the process of tungsten extraction and gold treatment. It is the main raw material for the production of tungsten powder and tungsten related products. It is usually obtained by calcining ammonium paratungstate. The traditional production process of tungsten trioxide is to place the powdered ammonium paratungstate in a fixed furnace or a rotary furnace for calcination.

Ammonium Paratungstate Preparation by Evaporation Crystallization

- Details

- Category: Tungsten Information

- Published on Monday, 23 December 2019 23:05

- Hits: 1702

Ammonium paratungstate is a kind of chemical substance, mainly white crystal, with two kinds of flake or needle, which is used to produce tungsten trioxide or blue tungsten oxide to make tungsten powder. It is also used to manufacture ammonium metatungstate and other tungsten compounds, and used as additives in petrochemical industry.

How to Prepare Tungstic Acid with Calcium Tungstate?

- Details

- Category: Tungsten Information

- Published on Monday, 23 December 2019 23:02

- Hits: 1807

.jpg)

Calcium tungstate is a very important chemical raw material, which is mainly used to produce ammonium paratungstate, tungsten trioxide, ferrotungsten, alloy steel, hard alloy, tungsten material, tungsten wire and tungsten alloy. It can be concluded that calcium tungstate is a kind of substance with wide application, and the preparation of tungstate from calcium tungstate is also a very interesting process.

Tungsten Sulfide Lubricating Material Upgrade for Carbon Brush II

- Details

- Category: Tungsten Information

- Published on Monday, 23 December 2019 21:09

- Hits: 2167

Tungsten disulfide lubricating material is a very excellent new material for wear reduction and energy saving. Its friction coefficient is only 0.03, and its performance is much better than the traditional graphite and molybdenum disulfide. It is known as the new "king of lubrication". It can not only be used in general lubrication conditions, but also in certain high temperature, low temperature, high load, high vacuum, radiation line and corrosive medium and other harsh working environment. It can be in powder state, or mixed with lubricating oil, grease, graphite, gold powder, plastic and other materials to make composite materials.

Doped Tungstate Application

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 December 2019 22:45

- Hits: 1755

Doped tungstate is the use of chemical or physical means to embed particles on the main lattice of catalyst, introduce new electronic center and new charge into the lattice, form lattice defects and change the type of lattice, adjust or change the energy band structure of catalyst to affect the movement of photogenerated electrons and holes, and ultimately lead to the change of photocatalytic activity of catalyst.

Tungsten Oxide Semiconductor Photocatalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 December 2019 22:16

- Hits: 1779

The narrow band gap (about 2.7eV) of WO3 makes it have better absorption in visible light area, which is obviously superior to the traditional TiO2 photocatalyst, but it also has the disadvantages of high carrier recombination rate and low visible light photocatalytic activity. The separation efficiency of photogenerated electron hole pair of WO3 can be improved by the control of graphene recombination, crystal structure and morphology, and then the photocatalytic activity can be improved.

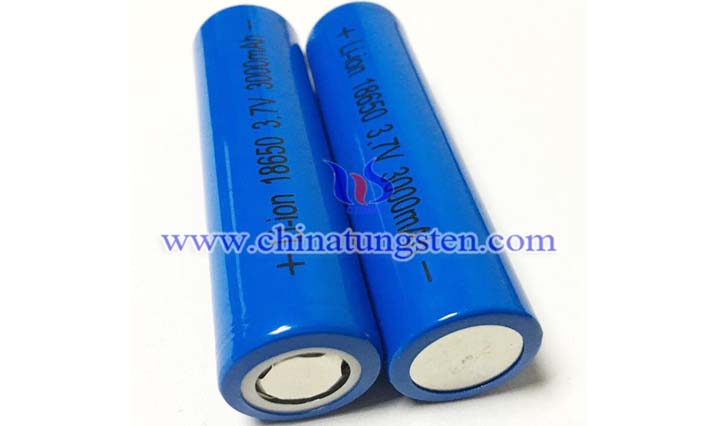

Defective Tungsten Oxide Lithium Battery May Free from Cobalt and Nickel

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 December 2019 21:50

- Hits: 2288

In order to develop the substitute of lithium battery and get rid of the dependence of cobalt and nickel metal as much as possible, foreign researchers have developed a very promising defective tungsten oxide lithium battery. To some extent, lithium battery can reduce the consumption of expensive metal materials.

sales@chinatungsten.com

sales@chinatungsten.com