Maintenance of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Thursday, 26 June 2025 19:15

- Written by Zhenghua

- Hits: 3

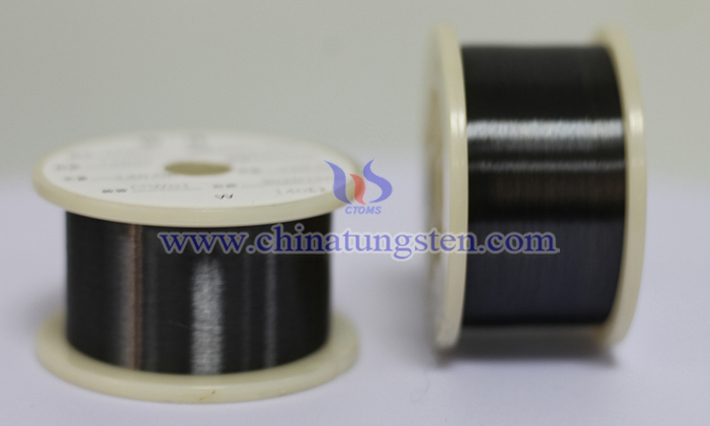

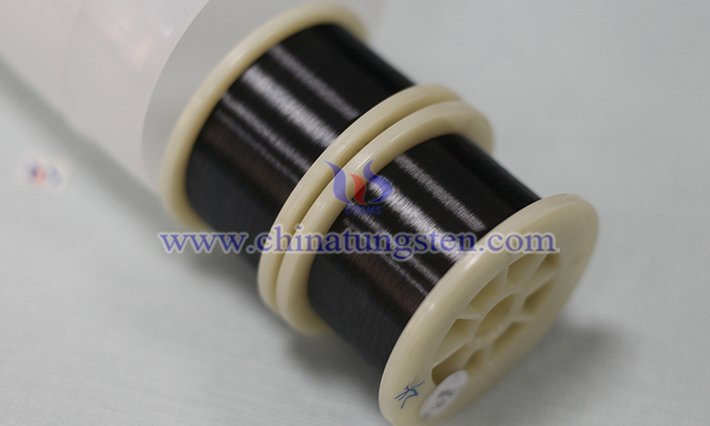

The maintenance of tungsten wire for glass heating is essential to extend its service life and ensure the heating effect. Tungsten wire is widely used in glass heating equipment due to its high melting point and excellent electrical conductivity, but it is easily damaged in high temperature and oxidizing environment, so scientific and reasonable maintenance methods are required.

1. Avoid Oxidation and Contamination

Tungsten wire is very easy to react with oxygen at high temperature to generate tungsten oxide, resulting in embrittlement or fracture. Therefore, when using, ensure that the heating equipment is in a vacuum or inert gas (such as nitrogen or argon) protection environment to prevent oxidation. Check the sealing before operation to avoid air infiltration. In addition, keep the surface of the tungsten wire clean to avoid oil, dust or chemical adhesion. It is recommended to wipe the surface of the tungsten wire with anhydrous ethanol to remove potential contaminants.

2. Control Working Temperature and Current

The life of the tungsten wire is closely related to the working temperature. Excessive temperature will accelerate the grain growth and aging of the tungsten wire. The current and voltage should be set reasonably according to the glass heating requirements to avoid overload operation. It is recommended to use a constant current power supply and calibrate the equipment regularly to ensure that the temperature is controlled within the tolerance range of the tungsten wire (generally below 2500°C). Use gradual heating at startup to avoid instant high temperature shock.

3. Regular Inspection and Replacement

Regularly check the appearance and resistance value of the tungsten wire. If the surface is discolored, deformed or the resistance is abnormal, it should be replaced in time. If the tungsten wire is found to be thinner or a local hot spot appears during use, it indicates that aging has occurred and should be handled as soon as possible to prevent breakage. Record the time of each use and formulate a replacement cycle to avoid sudden failures affecting production.

4. Storage and Installation Precautions

Unused tungsten wire should be stored in a dry, light-proof, dust-free environment to avoid moisture or oxidation. Wear clean gloves during installation to avoid hand sweat or grease from contaminating the tungsten wire. During installation, ensure that the tungsten wire is firmly fixed but not overstretched to avoid stress concentration and breakage.

5. Equipment Maintenance and Coordination

The life of the tungsten wire is also affected by the overall state of the heating equipment. Clean the inside of the equipment regularly, check the vacuum pump, seals and other parts to ensure there is no leakage. Keep the cooling system running normally to avoid overheating of the equipment and indirect damage to the tungsten wire.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com