Zirconium Tungsten Electrodes Invention of New Materials

- Details

- Category: Tungsten Information

New materials zirconium tungsten electrode metal welding materials technology invention relates to the field .  One kind of zirconium tungsten electrode , new materials, whose main ingredient is a constituent element of the entire content of 98 to 98.8 % of the tungsten, 0.91 to 1.2% zirconium . The invention belongs to metal welding materials technology category.

One kind of zirconium tungsten electrode , new materials, whose main ingredient is a constituent element of the entire content of 98 to 98.8 % of the tungsten, 0.91 to 1.2% zirconium . The invention belongs to metal welding materials technology category.

Currently in the arc welding , plasma welding thoriated tungsten alloy commonly used in the electrode material . Performance has improved in recent years has adopted a cerium tungsten alloy electrode, plasma cutting materials generally used in pure zirconium electrode . Thorium tungsten electrode materials, the biggest drawback is the α -ray intensity is extremely high, serious damage to the body's health and pollute the environment. Comparison with thorium tungsten electrode material , cerium tungsten electrode material generated during the operation α -ray dose is extremely small, only one-thousandth of thorium tungsten electrode material about other performance indicators can be at or near the thorium tungsten electrode material . These two materials in the AC arc electrode burning large , low life is another disadvantage that they co-exist . Although the performance of pure zirconium electrode material can reach thorium tungsten , cerium tungsten electrodes indicators, but the electrode material products cost more than the latter two electrodes 1 to 1.5 times higher . Countries, such as the United Kingdom in addition to tungsten thorium , cerium and zirconium tungsten electrodes , but also the use of a zirconium tungsten electrode material , its main ingredient is tungsten W , 99% zirconium oxide ZrO2 0.7 to 0.9 %, other impurities. In the same work norms , the ratio of cerium tungsten electrode tungsten material zirconium , thorium tungsten electrode material burning rates are low , long life, electrode temperature increased, the thickness of the workpiece increases, narrow kerf or welds , welding, cutting quality than cerium tungsten, thorium tungsten electrode materials , electrode materials cost less than pure zirconium , and in AC arc can be widely used. Coupled with the electrode material α -ray dose is small, reducing the damage to human and environmental pollution , to create the conditions for the automated production . However, the material brittle material , pressure processing performance is poor , the low yield machining electrode .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Emissivity of Tungsten Electrodes and Preventive Measures

- Details

- Category: Tungsten Information

On the market cerium tungsten, tungsten- lanthanum , yttrium tungsten, pure tungsten , zirconium , tungsten thorium tungsten electrodes . Tungsten cerium , lanthanum tungsten, pure tungsten , zirconium tungsten electrode non-radioactive ; thorium tungsten electrode is the world's highest market share of tungsten electrodes kind , accounting for over 70% of the world , but because thorium tungsten electrode grinding and polishing powder metallurgy and rolling will occur during radioactive contamination on the human body and the environment has a lot of harm , so European countries limit the production of the varieties electrode ; multivariate composite rare earth tungsten electrodes because they do not use radioactive elements thorium , to achieve a non-radioactive contamination in the field of green production and use. So in general there is a radioactive tungsten electrodes , mainly because more than 71% on the market using the thorium containing radioactive thorium tungsten electrode .  < br />

< br />

Measures to prevent radiation injury

( 1) Thorium tungsten rod should be a dedicated storage device , a lot of storage should be hidden in a metal box inside , and install the exhaust pipe .

( 2 ) Use of airtight cover welding, the operation should not open the cover , manual operation, the air must wear protective helmets or use other effective measures .

( 3 ) Shall be available exclusively to the grinding wheel thorium tungsten rod , wheel confidential install dust removal equipment, grinder debris on the ground should always be wet wipe and focus deep processing .

( 4 ) Grinding thorium tungsten rod should wear dust masks. After contact with thorium tungsten rod should wash their hands with soap and running water , and wash clothes and gloves .

( 5 )The selection of appropriate standards welding , to avoid excessive burning thorium tungsten rod .

( 6 ) As far as possible without the use of thorium tungsten rod cerium or lanthanum tungsten rod tungsten rod , because the latter two non-radioactive .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Radioactive Thorium Tungsten Electrode and Preventive Measures

- Details

- Category: Tungsten Information

TIG and plasma arc welding using thorium tungsten electrode containing 1-1.2 % of thorium oxide , thorium is a radioactive substance , in the welding process and thorium tungsten rod contact with the process, affected by radiation . Radiation acting on the body in two forms : one is external irradiation , the second is to enter the body through the respiratory and digestive systems occur in vivo exposure. From the right TIG and plasma welding mask a lot of investigation and determination proved that they are less harmful radioactivity , because daily consumption of thorium tungsten rods only 100-200 mg dose of radiation is minimal , little effect on the human body . But there are two cases must be noted: First, in the container welding, poor ventilation , dust in the radioactive particles may exceed health standards ; Second, when the grinding and the presence of thorium thorium tungsten rod tungsten rod locations , radioactive aerosols and radioactive dust concentration can reach or exceed health standards. Radioactive substances invade the body can cause chronic radiation sickness , mainly in the general functional state weakened , you can see the obvious debilitating weakness, decreased resistance to infectious diseases , weight loss and other symptoms.  < br />

< br />

Measures to prevent radiation injury

( 1) Thorium tungsten rod should be a dedicated storage device , a lot of storage should be hidden in a metal box inside , and install the exhaust pipe .

( 2 ) Use of airtight cover welding, the operation should not open the cover , manual operation, the air must wear protective helmets or use other effective measures .

( 3 ) Shall be available exclusively to the grinding wheel thorium tungsten rod , wheel confidential install dust removal equipment, grinder debris on the ground should always be wet wipe and focus deep processing .

( 4 ) Grinding thorium tungsten rod should wear dust masks. After contact with thorium tungsten rod should wash their hands with soap and running water , and wash clothes and gloves .

( 5 ) The selection of appropriate standards welding , to avoid excessive burning thorium tungsten rod .

( 6 ) As far as possible without the use of thorium tungsten rod cerium or lanthanum tungsten rod tungsten rod , because the latter two non-radioactive .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Features of Fake Gold

- Details

- Category: Tungsten Information

Fake gold actually is often shinier than real gold. Real gold, particularly when it is in nugget form, has a yellow, almost waxy sheen. This sheen will not change regardless of what light it is in. Most types of fake gold may look shinier or duller in different lights, and may appear almost silver at times. Real gold is also malleable, while typical fake gold is hard. Fake gold is also lightweight in most cases, and even plating will not make a piece of fake gold weigh even a seventh of what real gold does in most cases.

Gold plated Tungsten Product Manufacturer & Supplier: Chinatungsten Online - http://paper-weight.cn/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Zirconium and Zirconium Tungsten Electrode

- Details

- Category: Tungsten Information

Zr (Zirconium) is a chemical element , its chemical symbol is Zr, its atomic number is 40 , is a silvery white metal of high melting point , pale  gray. Density of 6.49 g / cm 3 . Melting point 1852 ± 2 ℃, boiling point 4377 ℃. Valence of +2, +3 and +4 . The first ionization energy of 6.84 eV. Easy to form a surface layer of zirconium oxide film having a gloss similar to the appearance and steel . Corrosion -resistant , can be dissolved in hydrofluoric acid and aqua regia ; high temperature , can be used with non-metallic elements and many metal elements react to form a solid solution compound.

gray. Density of 6.49 g / cm 3 . Melting point 1852 ± 2 ℃, boiling point 4377 ℃. Valence of +2, +3 and +4 . The first ionization energy of 6.84 eV. Easy to form a surface layer of zirconium oxide film having a gloss similar to the appearance and steel . Corrosion -resistant , can be dissolved in hydrofluoric acid and aqua regia ; high temperature , can be used with non-metallic elements and many metal elements react to form a solid solution compound.

Zirconium tungsten electrodes pure tungsten electrode in order to improve the welding conditions at high load melt easily contaminated workpiece itself and the development of an electrode variety drawbacks , the greatest feature of the electrode is at high load currents , the ends of such an electrode can be maintained a spherical tungsten reduced infiltration phenomenon , and has good corrosion resistance .

Zirconium tungsten electrodes and pure tungsten electrodes , can only be of the AC welding work environment .

Zirconium tungsten electrode in AC environment, good weldability . Especially in the case of high load currents , zirconium tungsten electrodes shown superior performance of the other electrode can not be replaced .

In welding, the end portion of the tungsten electrode of zirconium to maintain a reduced spherical tungsten infiltration phenomenon , and has good corrosion resistance .

Since the emergence of other alternative products , zirconium tungsten electrode demand will have a decreasing trend . Main alternative product is lanthanum tungsten electrode .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Zirconium Tungsten Models and Features

- Details

- Category: Tungsten Information

Zirconia doped tungsten, zirconium tungsten electrodes produce. Specific data as follows:

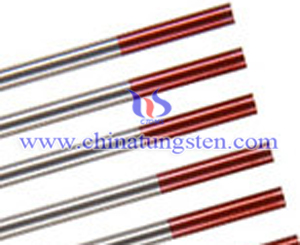

Other grades dopant doping doping electron work function color coating head

WZ3 ZrO2 0.20 ~ 0.40% <0.20% 2.5 ~ 3.0 Brown

WZ8 ZrO2 0.70 ~ 0.90% <0.20% 2.5 ~ 3.0 White

Zirconium tungsten electrodes and pure tungsten electrodes, can only be of the AC welding work environment.

Zirconium tungsten electrodes in AC environment, good weldability. Especially in the case of high load currents, zirconium tungsten electrodes shown superior performance of the other electrode can not be replaced.

In welding, the end portion of the tungsten electrode of zirconium to maintain a reduced spherical tungsten infiltration phenomenon, and has good corrosion resistance.

Since the emergence of other alternative products, zirconium tungsten electrode demand will have a decreasing trend. Main alternative product is lanthanum tungsten electrode.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Gradually Being Forgotten Zirconium Tungsten Electrode

- Details

- Category: Tungsten Information

Now there are many types of tungsten electrodes , the new generation and application of bulldozing will gradually phase out old products. Tungsten also has been the development of innovation . Especially in relatively hot composite rare earth tungsten electrodes . But I have used a total of tungsten electrodes also has good quality , with so not being taken seriously , but in the history of the tungsten electrode Send a connecting link between the river played a role .

Introduced in front of lanthanum tungsten electrodes , thoriated tungsten electrodes , said today that the zirconium tungsten electrode . Zirconium tungsten electrodes in order to improve the motor innocent large tungsten at high load conditions, contamination of the workpiece is easy to melt their drawbacks of an electrode for the development of varieties , the biggest feature is the high load currents , the end of this motor a spherical portion can be maintained to reduce the phenomenon of infiltration of tungsten , with good corrosion resistance.

Zirconium tungsten electrodes are based on the zirconia containing a small amount . Once thoriated tungsten electrode and the common electrode zirconium tungsten electrodes are , generally speaking in nature , zirconium tungsten electrodes is the best non-radioactive tungsten electrodes . Zirconium tungsten electrodes in the case of the use of alternating current with good performance.

Lanthanum tungsten electrode application and now composite rare earth tungsten electrodes gradually occupied the tungsten electrodes market. The use of zirconium tungsten electrode less .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Zirconium Tungsten Electrode Characteristics and Uses

- Details

- Category: Tungsten Information

Zirconium Tungsten Electrode Characteristics

In welding, the end portion of the tungsten electrode of zirconium to maintain a reduced spherical tungsten infiltration phenomenon , and has good corrosion resistance . Since the emergence of other alternative products , zirconium tungsten electrode demand will have a decreasing trend . Main alternative product is lanthanum tungsten electrode .

The Use of Zirconium Tungsten Electrode

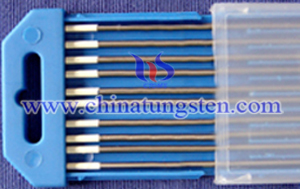

Zirconium tungsten electrodes , but also for radiation quality welding . Requires minimal best application tungsten contamination . Zirconium tungsten electrodes are generally applied alternating current, not recommended for direct current. Tungsten electrodes made of zirconium and its alloys for Mg AC welding . zirconium tungsten electrode welding special to pure tungsten electrodes located and thorium tungsten electrode, is to improve the pure tungsten electrode welding conditions at high load melt easily under their own further pollution and the development of the drawbacks of the workpiece tungsten electrodes product. 10 pcs / plastic box , the length is 150mm or 175mm, 1000只per carton .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Zirconium Tungsten Electrodes and Characteristics of The Main Components

- Details

- Category: Tungsten Information

Zirconium tungsten electrode is the main component

Zirconium tungsten electrodes with a small amount of zirconia . Zirconium tungsten electrode welding characteristics , in general, in pure tungsten electrodes and thoriated tungsten electrodes. In AC welding , zirconium tungsten electrode is the most common , because welding easier than pure tungsten arc , and the arc beam stability, but also can be a good prevention of pollution , carrying capacity is also good, from a performance point of view, overall zirconium tungsten electrode is the best non-radioactive tungsten electrodes .

The main ingredient is the element content in the total composition 98 to 98.8 % tungsten , 0.91 to 1.2% zirconium , 0.01 to 0.07% of yttria of 0.01 to 0.02% of cobalt .

Zirconium tungsten electrode characteristics

Zirconium tungsten electrodes and pure tungsten electrodes , can only be of the AC welding work environment . Zirconium tungsten electrode in AC environment, good weldability . Especially in the case of high load currents , zirconium tungsten electrodes shown superior performance of the other electrode can not be replaced .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Electrode Manufacturing Method of The Invention of Cerium

- Details

- Category: Tungsten Information

Cerium tungsten electrode material is a non -radioactive, non- consumable refractory metal electrode material , applied to the inert gas-shielded arc welding , plasma welding , cutting, coating and smelting , the laser light source and the gas discharge light source technologies such as the electrode , and a vacuum electron beam coating cathode filaments , etc. The present invention uses powder metallurgy process , strict control of process parameters, to prepare a cerium oxide content of 1.0 to 4.5 % cerium tungsten electrode material , thus overcoming long as people think cerium oxide containing more than 1.0 % cerium tungsten electrode material embrittlement problem occurs .

Cerium tungsten electrode material manufacturing methods and equipment belonging to the field of chemical and metallurgical techniques . The first aspect of the present invention is to use liquid - liquid mixing replace the existing liquid - solid mixing , the additive , tungsten ceria group in the most uniform dispersion , thus greatly improving the processing of the tungsten electrode material Ce properties and performance ; second aspect of the present invention is to replace the existing spray- drying and evaporation of the mixing disc drying , the tungsten powder particle size , particle size distribution and particle shape can be controlled , thereby ensuring the processing performance , easy , continuous and automatic and mass production . Cerium tungsten electrode material for the promotion and application of the foundation.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com