How Will Fake Gold React to an Acid Test?

- Details

- Category: Tungsten Information

Gold is so soft that when jewelry is made from it, it is usually alloyed with one or a combination of copper, nickel, and silver. If gold jewelry is immersed in an individual acid, the gold itself will not dissolve, although the alloying metal does dissolve. If a chunk of metal is fake gold--if it consists of a metal sample in which there is very little to no gold--it will dissolve in nitric acid.

Density First

Before treatment with acid, the density of the jewelry should be evaluated. Gold has a density of 19.3 grams per cubic centimeter of metal. Copper and nickel are less dense than that--8.96 and 8.91 respectively. Silver has a density of 10.49. If the density of the jewelry is not appreciably more than 9, the piece is fake. Even if it has a trace of gold in it, perhaps a plated covering, it is less than the 10-Karat designation of the lowest grade of solid gold jewelry.

Pure Gold

Pure gold, called also 24-Karat gold, dissolves in alkali cyanide and in a few other unusual substances. It will not, however, dissolve in individual mineral acids. It does dissolve in certain combination acids, most notably "aqua regia" (a mixture of concentrated hydrochloric and nitric acids). Gold dissolved in aqua regia produces a dark amber-to-orange color.

Gold plated Tungsten Product Manufacturer & Supplier: Chinatungsten Online - http://paper-weight.cn/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

What Is Tungsten Gold?

- Details

- Category: Tungsten Information

Shoppers who are looking to buy real gold may unfortunately purchase tungsten gold, or fake gold, by accident. Fake tungsten gold bars are cheap substitutes for the real thing.

Background

Tungsten gold is considered the Ancient Metal of Kings. Tungsten is also called “the heavy stone.”

Pricing

While gold is priced in the tens of thousands per pound, tungsten costs less than $100 per pound. Charging the real gold price for tungsten gold leads to a huge profit.

Qualities

Tungsten gold is scratch-resistant and lightweight. Per cubic centimeter, it has a density of 19.25 grams at room temperature. At liquid density, it is 17.6 grams per cubic centimeter.

Determining Type of Gold

It’s difficult for the average person to quickly spot tungsten gold. However, those who are experienced in the gold industry can find ways to determine if the gold is fake or not.

Purity of Other Metals

Silver and platinum tend to be pure, since the materials are often melted down for making cell phones and catalytic converters.

Gold plated Tungsten Product Manufacturer & Supplier: Chinatungsten Online - http://paper-weight.cn/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Bucking Bar End-Effector For Upsetting a Rivet

- Details

- Category: Tungsten Information

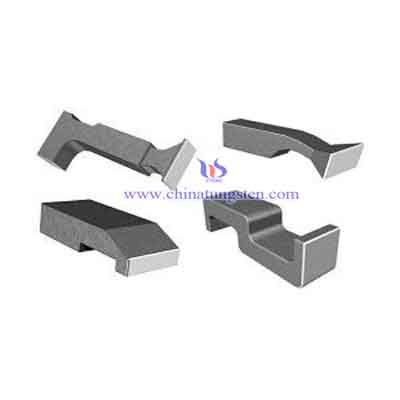

A bucking bar assembly that positions a bucking bar for clamping a first panel and a second panel along a lap joint and upsets a rivet to fasten the first panel to the second panel at the lap joint. The assembly includes a lateral carriage system for moving the bucking bar along a length of the lap joint, and a rotational carriage system for rotating the bucking bar relative to the lateral carriage.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

L-shaped Bucking Bar

- Details

- Category: Tungsten Information

The bucking bar includes an L-shaped bucking die having a wide section and a thin angular section capable of sliding between an obstacle and the shank. The L-shaped bucking bar consists of Tungsten Carbide. The bucking bar also includes a bucking bar arm coupled to the wide section of the L-shaped bucking die for positioning the thin angular section of the bucking die between the obstacle and the shank of the rivet

A metal tool used to flatten the rivet's shank into a driven button during the riveting process. The bucking bar is used as an anvil to react the forces being driven into the rivet with a rivet gun, thus deforming the rivet.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Two Forms of Bucking Bar

- Details

- Category: Tungsten Information

bucking bars in general and more particularly to a tool which has a longer serviceable life, an appreciably lower fatigue factor and a lower decibel shock and vibration rating in use.

The bucking bars of this include two principal parts separated by a low-recoil impact-resistant urethene plastic member, to absorb the shock load and minimize vibrational effects which contribute to the otherwise high-decibel rating of the tool. They are fastened together by means that allow some relative movement between them but keeps the cushioning member in contact with both parts at all times.

In one of the preferred forms, the handle part is formed with an undercut notch towards the toolhead and the latter is formed for engagement therein so that both axial and lateral thrust loads are absorbed in the tool. This particular tool is also reversible in that the end of the handle part is also formed for taking an impact load and the head end may be used as the handle.

Another form includes mating cylindrical parts with a blind end separated to absorb the shock load.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

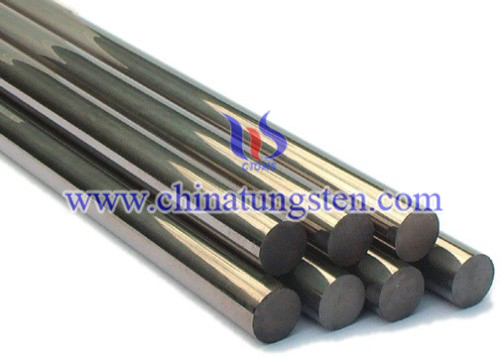

Tungsten Alloy Swaging Rod & 9K11 Malyutka

- Details

- Category: Tungsten Information

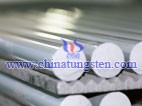

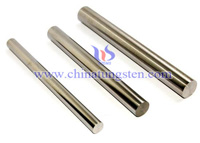

Tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungtsen alloy swaging rod can be used for 9K11 Malyutka.

The 9K11 Malyutka is a manual command to line-of-sight (MCLOS) wire-guided anti-tank guided missile system developed in the Soviet Union. It was the first man-portable anti-tank guided missile of the Soviet Union and is probably the most widely produced ATGM of all time—with Soviet production peaking at 25,000 missiles a year during the 1960s and 1970s. In addition, copies of the missile have been manufactured under various names by at least five countries.

With the high density and high hardness, tungsten alloy swaging rod is widely used for 9K11 Malyutka to penetrate amor and destroy target.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod & HJ-9

- Details

- Category: Tungsten Information

Tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungtsen alloy swaging rod can be used for HJ-9.

The HJ-9 is an advanced, third-generation anti-tank missile system deployed by the People's Liberation Army.

The missile was developed by Norinco, and one of the chief designers was Yang Chunming. It is similar in appearance to the Israeli MAPATS (man portable anti-tank system), causing speculation about the link between the two missiles. It is also similar to the South African Ingwe antitank missile, and like its Israeli and South African counterparts, its guidance is laser-beam-riding.

With the high density and high hardness, tungsten alloy swaging rod is widely used for HJ-9 to destroy amor vehicles and bunkers.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod & HJ-8

- Details

- Category: Tungsten Information

Tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the  processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungtsen alloy swaging rod is widely used in HJ-8.

processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungtsen alloy swaging rod is widely used in HJ-8.

The HJ-8 or Hongjian-8 is a second generation tube-launched, optically tracked, wire-guided anti-tank missile system which was originally deployed by the People's Liberation Army since the late 1980s. Pakistan produces this missile system under licence as the Baktar-Shikan at Kahuta Research Laboratories. It is able to defeat explosive reactive armour (ERA).

With the high density and high hardness, tungsten alloy swaging rod is widely used for HJ-8 to destroy amor vehicles and bunkers.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod & HJ-10

- Details

- Category: Tungsten Information

Tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungtsen alloy swaging rod is widely used in HJ-10.

HJ-10 is a series of indigenously developed and highly classified (as of 2011) Chinese anti-helicopter / anti-tank missiles, they are the primary weapon of the CAIC WZ-10 attack helicopter. Many sources have claimed that this little-known missile is the Chinese equivalent of the AGM-114 Hellfire, although the details of the actual performance of the HJ-10 have yet to be released officially by the Chinese government or other credible sources to confirm such claims. Several derivatives of the HJ-10 have also been developed by China, they are all believed to be in limited service with the Chinese military for evaluation purposes.

With the high density and high hardness of tungsten alloy swaging rod, HJ-10 can destroy tanks, helicopters or bunkers.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod for MSS-1.2

- Details

- Category: Tungsten Information

Tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungtsen alloy swaging rod is widely used in MSS-1.2.

MSS-1.2 is a Brazilian personal missile launch system with laser guidance used for close-range fighting. It is the standard personal missile launch system of the Brazilian army and marine corps. The MSS 1.2 has a range of 500 to 3,000 m and can be used against tanks, armoured vehicles, infantry, bunkers, small buildings, boats, aircraft, and helicopters.

The missile is equipped with a warhead type hollow charge and a two-stage propulsion system. Guidance is performed by a laser beam projected by the fire control system. Similar in performance to the Russian 9M123 Khrizantema, it is meant to compete with other next generation missiles. The MSS-1.2 was designed to deal with current and future armored threats such as Russian T-90, American M-1 Abrams and British Challenger 2 tanks, but can also be used against low-altitude aircraft such as helicopters and unmanned aerial vehicles. It has successfully breached more than six meters of concrete in tests carried out by the Brazilian army.

Tungsten alloy swaging rod has high density and high hardness. So MSS-1.2 used tungsten alloy swaging rod as its warhead to penetrate armor or destroy bunker.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com