Great Magnetoresistance of Tungsten Telluride

- Details

- Category: Tungsten's News

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Isopropyl Alcohol's Widespread Applications

- Details

- Category: Tungsten's News

IPA ,also known as isopropyl alcohol, is used as a low-cost solvent in many industrial and consumer products, it is also used as the extraction agent. According to the European Solvents Industry Group (ESIG) analysis, in 2001 in Europe, the demand of intermediate accounted for 32% of IPA consumption, 14% as anti-icers, 13% for coatings and resins, 9% for medicine , 4% for food, 3% for inks and adhesives. It is also used as solvent for oil and gum, and the preparation of fish feed concentrate.

Low-grade IPA can be used as vehicle fuel. the amount of IPA used as raw materials of acetone in production declines. There are several compounds synthesized by the IPA, the main compounds is methyl isobutyl ketone and many esters. The general purity of Anhydrous IPA is 99%, the premium (used for making perfume and medicine) IPA purity is greater than 99.8%.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Production Technology of Isopropyl Alcohol

- Details

- Category: Tungsten's News

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Demand Capacity of Isopropyl Alcohol

- Details

- Category: Tungsten's News

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

High-Quality Low-Cost Single Tungsten Disulfide Realize a Large-Area Preparation II

- Details

- Category: Tungsten's News

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

High-Quality Low-Cost Single Tungsten Disulfide Realize a Large-Area Preparation I

- Details

- Category: Tungsten's News

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Rare Earth Symposium will Be Held Soon, Attention on Rare Earth and Tungsten

- Details

- Category: Tungsten's News

Last week, nine tin enterprises in the country decided cut back production of 17,000 tons in 2016, which take place about 12% of national yield. It’s expected that it doesn’t exclude the possibility of purchasing and storage business in the future, reduction of output and purchasing and storage tin supply and demand situation is expected to improve.

MIT Scientists have Developed an Improved Tungsten Wire Light Bulbs

- Details

- Category: Tungsten's News

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Diselenide-Thin Flexible Solar Cells Material

- Details

- Category: Tungsten's News

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

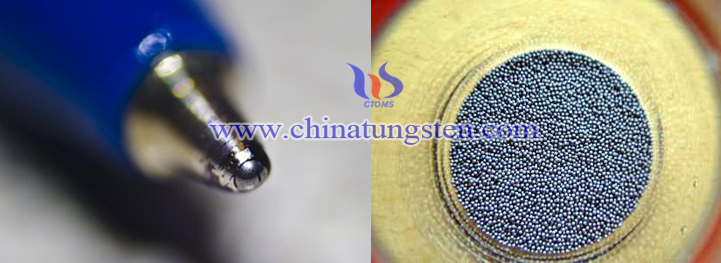

“Embarrass” of Tungsten Carbide Ball for Pen Using

- Details

- Category: Tungsten's News

It is reported that China has become the largest country of pen manufacture. However, in the back of a string of prides, such as 3,000 the enterprises, 200,000 employees, 40 billions of annual output, it still has the lack of core technology and highly depends on the bead import. Some related experts consider that the nib and the ink are the major parts of the pen, and the nib can be specifically divided in to the bead and the ball seat. At the present, tungsten carbide (WC) ball is the most widely used in the world, which China can not only meets the domestic needs, but also can be exported plenty. In addition, tungsten carbide ball for pen using can be specifically divided into WC-based cemented carbide, WC-TiC-based cemented carbide, Tic-based cemented carbide, Cr3C2-based cemented carbide and so on. WC-based cemented carbide is the most widely using for pen, although different basis of ball has different advantages and properties. Therefore, according to different ink and the material of nib, we should choose the proper ball and it can improve the quality of production.

While the production of the ball seat, either the equipments or the materials are mastered by Switzerland, Japan and other countries. “The small nib by traditional process requires more than 20 procedures, which should be manufactured separately”, Chen said, the honorary president of China Writing Instrument Association. So domestic pen manufacturers start to use the integrative production facility of other countries, and it has high demand on the raw materials, which domestic stainless steel wire is not suitable. Besides, the pen also has 5 grooves of ink flowing, which the precision should reach one of a thousand of millimeters and any deviation of the angle, the pressure, the bead, the nib and the ink grooves will have an effect on the fluency and the service life of the pen. Therefore, China allocated nearly 60 million to support the relevant research institutions, enterprises for the manufacture center of the ink, stainless steel wire tip, machining equipment to carry out scientific and technological research. However, acceptance of new technology and equipment business also requires a process, in order to remove this “embarrass”, we should find some way to increase the promotion of new technologies.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com