WO3 Catalytic Fuel Cell Vehicle Eases Global Warming

- Details

- Category: Tungsten's News

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

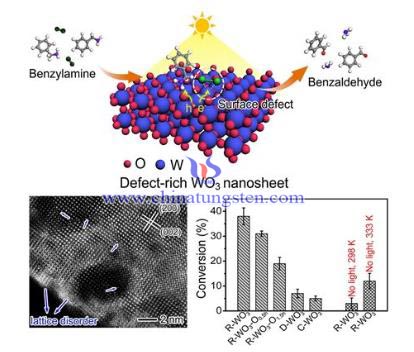

Defect-Rich Tungsten Trioxide Nanosheet Photocatalyst

- Details

- Category: Tungsten's News

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

"Made In China 2025" Promotes the Development of Tungsten Heater

- Details

- Category: Tungsten's News

As the first decade guideline of "three-step" strategy for construction of manufacturing power of China, "Made In China 2025" depicts a path for Chinese manufacturing from large to strong, which has been gained high-level attention by Communist Party of China (CPC). In early July 2015, the State Council set up national manufacturing power construction leading group, and the vice-premier Ma Kai is the group leader, and there are more than 20 government departments involved in this group. This group has held the third meeting and established a consultative committee for construction strategy of national manufacturing power, and builds up intersectoral links joint-action mechanism and actively mobilizes multi-power and enthusiasm.

Over the past year, for the implementation of the "Made in China 2025", the government mainly carried out three aspects. Firstly, the government prepared and issued the "1 + X" plan. Secondly, the government formulated a number of supporting policies. CBRC revised the "Commercial Bank M & A Loan Risk Management Guidelines" to encourage the support of commercial banks to manufacturing concern. It would work with the Ministry of Industry and Information Technology of the People’s Republic of China to further improve the financing guarantee system. The introduction of these supporting policies, mainly in order to provide the reasonable support for necessary innovation and development for manufacturing.

The third is to strengthen the guidance of local, promote development of regional differences. Some effects and implementation of policies and the major projects has been initially apparent. For example, “Enterprise R & D Expenses Plus Deduction Policy” further stimulates industrial enterprises, especially SMEs (Small and Medium Enterprises) innovation and dynamic development. Future development of "Made in China 2025" will be more perfect, be more conducive to long-term development of business volume, so that it will greatly facilitate the tungsten heater and other tungsten enterprises development.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 May Be Catalyst of Black Tech Fuel Cell

- Details

- Category: Tungsten's News

Recently, Nissan release the automobile solid oxide fuel cell (SOFC): vehicles which equipped with solid oxide fuel cells will use bio-ethanol rather than the liquid hydrogen. Produce ethanol reformer hydrogen combines with oxygen in the air in a fuel cell to produce electricity, then discharging water. According to the source, this system is more efficient than the existing hydrogen fuel cell system, which the recharge mileage can reach about 600 km. what kind of black tech is SOFC?SOFC is the third generation of the fuel cell, a solid-state chemical mean which direct converted efficiently and environmentally friendly the chemical energy which is stored in the fuel and oxidizer to electric energy at high temperature, a fuel cell which is considered to be widely applied as the proton exchange membrane fuel cell (PEMFC) in the future.

Recently, Nissan release the automobile solid oxide fuel cell (SOFC): vehicles which equipped with solid oxide fuel cells will use bio-ethanol rather than the liquid hydrogen. Produce ethanol reformer hydrogen combines with oxygen in the air in a fuel cell to produce electricity, then discharging water. According to the source, this system is more efficient than the existing hydrogen fuel cell system, which the recharge mileage can reach about 600 km. what kind of black tech is SOFC?SOFC is the third generation of the fuel cell, a solid-state chemical mean which direct converted efficiently and environmentally friendly the chemical energy which is stored in the fuel and oxidizer to electric energy at high temperature, a fuel cell which is considered to be widely applied as the proton exchange membrane fuel cell (PEMFC) in the future.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Concentrate Price Unexpected Goes Up

- Details

- Category: Tungsten's News

Since the price of tungsten concentrate and ammonium paratungstate hit the bottom of 60,000RMB/ton, it stoped falling and went up slightly last week. The change in market is faster than expected, for most enterprises thought the market will turn better at the end of August.

Tungsten Carbide Business Hit By Oil&Gas Malaise

- Details

- Category: Tungsten's News

The full-year profits took a hit from the on-going malaise in the Oil&Gas sector, although management sounded an optimistic note on the potential of its products, including graphene.

The advanced engineering materials group recorded losses before tax of £1.8m, up from £0.9m in 2015.

Revenues declined 10% from £4.98m to £4.4m, with improved sales at its thermal products arm failing to offset a drop in Hard Wear products unit.

Its tungsten carbide business took a hit from the downturn in the oil and gas sector, reporting sales for the year to end March of £3.1mln compared to £4.6mln in 2015, but it said all three of its divisions, hardware, thermal and graphene, had made progress.

Sales at the former, which manufactures microporous copper foam, improved from £0.4m to £1.3m, benefitting from the purchase of its heat sink business in February 2015.

In parallel, Hard Wear product sales were hit by the adverse environment in the oil and gas market, although new opportunities were emerging in defence and aerospace, the company said in a statement.

The unit makes sintered tungsten carbide business for "arduous environment" applications, primarily in Oil&Gas.

Since the end of the reporting period, the company had closed four partnerships to introduce its grapheme products into four key markets: batteries, carbon fibre products and enhanced composites for 3D printing and the aerospace industry.

It had also negotiated its first OEM contract for the use of low profile copper foam heat sinks in consumer devices.

Cash at period end was down from £3.5m one year ago to £1.6m, with £1.26m having been funneled into operating activities and another £276,000 towards the purchase of intangible assets.

Regarding the company's outlook, the board said it remained confident it was on track to benefit from progress made, saying that graphene was moving quickly towards commercial applications, while thermal products had moved into commercial production.

As of 15:56 BST shares in AIM-listed Versarien were 6.38% down to 11.0p.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 Denitration Catalyst Devotes to Green Energy

- Details

- Category: Tungsten's News

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Active Stage of Innovating Promotes the Development of Tungsten Heater

- Details

- Category: Tungsten's News

Recently, entrepreneurs survey system of the Development Research Center of the State Council issued "China Enterprise Innovation Trends Index," it was said that the current Chinese enterprises began to enter the active phase of innovation, the main trend of China's economy will be innovation as motivation for the future development.

As early as the end of 2015, Chinese entrepreneurs organized the 23rd nationwide annual follow-up survey of enterprise operation, according to the survey, the average score of Chinese enterprise innovation trends index was 54.95. As it can be seen from the survey results, there were eighty percent of enterprises have realized the importance and urgency of innovation, they were willing to input more manpower and material resources for innovation. Innovation potential score was 64.68, innovation inputs was obtained a score of 67.83. Subsequent year the number of entrepreneurs planed to add the “total innovation investment” accounted for 55.1%, unchanged entrepreneurs accounted for 39.8%, and those entrepreneurs who reduce investment only accounted for 5.1%. This showed that companies already have a good potential for innovation and they all have high willingness to innovate.

The survey also found that the improvement of the quality of products, environment, new markets and other aspects of Chinese enterprises are showing a positive effect for innovation. Entrepreneurs continuously improve product and service quality, they pay attention to the impact on the environment healthy and safe. This will not only improve the degree of innovation of enterprises, but also improve the health of the entire market transactions. This makes it possible to maintain the vitality of tungsten enterprises to survive in the competition. Innovative products will greatly facilitate the application of tungsten heater and transactions, improving the downturn state of the tungsten market. Although many companies focus on innovation, but the execution is not enough, creative talents is still a big problem that many people have employment abroad, China still needs to make efforts.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nonferrous Metals Industry Turns Better, Overcapacity of Tungsten Heater still Exists

- Details

- Category: Tungsten's News

It was reported that recently, the National Bureau of Statistics of the People’s Republic of China issued management situation of nonferrous metals industry in the first half of 2016. It said that the smooth operation of it and the price of the main product had small rising, efficiency of the industry continued to be improve, the main business income was 2.2074 trillion RMB, an increase of 2.6% and profit was 68.74 billion RMB, an increase of 8.6%. Deficit of the industry reduced to some extent, amount of loss of enterprises was 17.6 billion RMB, down 11.8%, wherein the aluminum enterprises lost 4.05 billion RMB, down 22.4%. The industry fixed assets investment completed was 232.7 billion RMB, an increase of 2%.

It is clear from the above data that Chinese nonferrous metals industry continues to turn better, and the prices also get better. This is related to China's real estate rebound, increased investment and other reasons, it is also affected by industry output adjustment. But for long-term development perspective, because the long-term production of tungsten heater and other non-ferrous metal industry overcapacity, market supply and demand are imbalance and have other issues, so non-ferrous metals industry operators are facing difficulties.

Since 2014, China's major non-ferrous metal prices continued to fall dramatically, the industry is in loss status for a long time, there are a great majority of enterprises due to low prices and cannot afford to be out of the market. Coupled with the global economy in recent years are in a volatile situation, which made development of China's nonferrous metals industry become more difficult. With the recent release of relevant policies and measures to improve the continuous problem of production capacity, non-ferrous metal industry gradually improved, but if China wants the whole industry can achieve key breakthrough, she also needs to handle problem of the non-ferrous metal product application technology, product quality, engineering and construction standards and others.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Upgrade of Prospecting Potential in Chifeng City Promotes the Development of Tungsten Heater

- Details

- Category: Tungsten's News

Chifeng City is a prefecture-level city in southeastern Inner Mongolia, People's Republic of China. It borders Xilin Gol League to the north and west, Tongliao to the northeast, Chaoyang (Liaoning) to the southeast, and Chengde (Hebei) to the south. On July 10, project acceptance meeting of "Home Town of China Nonferrous Metals • Comprehensive Utilization Research of Tailings and Metallogenic Regularity of Nonferrous Metals," was held in Beijing. The project "Comprehensive Utilization Research of Tailings" carried out systematic surveys and studies for lead, zinc, copper, silver, and molybdenum, tin and other non-ferrous metal deposit in Chifeng region and did varying degrees of research on more than 40 typical deposit. And the main types of non-ferrous metal deposits of Chifeng region can be concluded as follows which are based on this study: hydrothermal vein type, skarn, porphyry, volcanic - subvolcanic hydrothermal, sedimentary water spray pattern. What’s more, Chifeng area can be divided into three metallogenic period: Permian, Early - Middle Triassic, Late Jurassic - Early Cretaceous, for further opening up new ideas for prospecting ore in Chifeng region. Overall research projects provide a strong scientific basis for further prospecting work in Chifeng city.

Chifeng City is a prefecture-level city in southeastern Inner Mongolia, People's Republic of China. It borders Xilin Gol League to the north and west, Tongliao to the northeast, Chaoyang (Liaoning) to the southeast, and Chengde (Hebei) to the south. On July 10, project acceptance meeting of "Home Town of China Nonferrous Metals • Comprehensive Utilization Research of Tailings and Metallogenic Regularity of Nonferrous Metals," was held in Beijing. The project "Comprehensive Utilization Research of Tailings" carried out systematic surveys and studies for lead, zinc, copper, silver, and molybdenum, tin and other non-ferrous metal deposit in Chifeng region and did varying degrees of research on more than 40 typical deposit. And the main types of non-ferrous metal deposits of Chifeng region can be concluded as follows which are based on this study: hydrothermal vein type, skarn, porphyry, volcanic - subvolcanic hydrothermal, sedimentary water spray pattern. What’s more, Chifeng area can be divided into three metallogenic period: Permian, Early - Middle Triassic, Late Jurassic - Early Cretaceous, for further opening up new ideas for prospecting ore in Chifeng region. Overall research projects provide a strong scientific basis for further prospecting work in Chifeng city.

The project "Comprehensive Utilization Research of Tailings and Green Management of Chifeng City" caried out procedural model for the comprehensive utilization of metal mine tailings investigation, which compromises the technology portfolio of test analysis for tailings, including quantitative analysis for chemical composition of tailings, mineral composition, particle size and texture of the three systems, providing comprehensive support data for subsequent disposal and utilization program. On the other hand, carried out systematic investigation for the selection of 10 from Chifeng nonferrous metals, iron, gold and tungsten mine tailings, and made preliminary recommendations for its disposal and application. This will be beneficial to subsequent development of tungsten products, such as tungsten heater.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com