Reason for Adding Rare Earth Oxides to Tungsten Electrodes

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 September 2025 14:07

Metal tungsten, due to its high melting point, strong electron emission capability, and low vapor pressure, has become the preferred choice for thermionic emission materials. However, its high electron work function, elevated electrode tip temperature, and tendency for grain growth lead to unstable arc beams, difficult arc initiation, and a short service life in pure tungsten electrodes, limiting their use to alternating current welding. To overcome these drawbacks, manufacturers often add rare earth oxides with low electron work functions, such as lanthanum oxide, cerium oxide, and yttrium oxide, to pure tungsten materials. This not only increases the recrystallization temperature of the product but also enhances electron emission.

Requirements of Diamond Wire for Tungsten Core Wire

- Details

- Category: Tungsten Information

- Published on Monday, 01 September 2025 19:28

As one of the primary cutting tools for high-hardness brittle materials, the quality of diamond wire depends not only on the production method, the size and distribution density of diamond particles, but also on the performance and thickness of the tungsten wire core. Generally, cutting wire produced using an electroplating process offers stronger cutting ability compared to that made with resin binders, primarily due to better diamond consolidation. The size of diamond particles should be moderate and evenly distributed; if the particles are too large, the cutting wire becomes too thick, increasing silicon wafer loss rates, whereas if they are too small, the cutting effectiveness decreases.

Tungsten Alloy Ring

- Details

- Category: Tungsten Information

- Published on Monday, 01 September 2025 15:40

In daily life, as you pass by a machining workshop, you might catch a glimpse of a shiny metal ring on a robotic arm. Step into a medical device research lab, and you might find it quietly nestled within a critical piece of equipment. These rings, though seemingly ordinary, have a unique "heritage"—they are tungsten alloy rings.

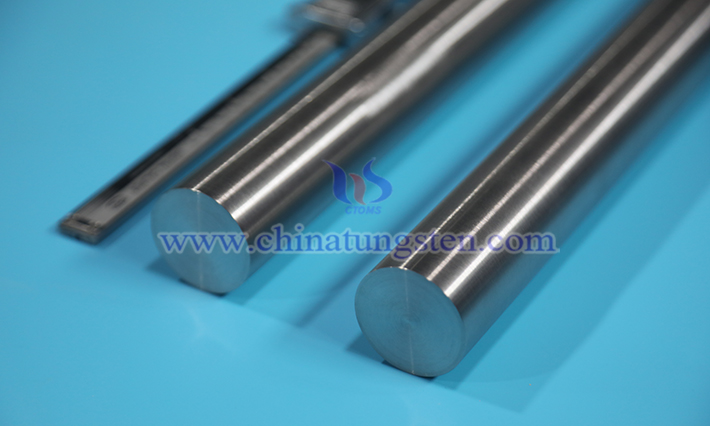

Tungsten Alloy Rod

- Details

- Category: Tungsten Information

- Published on Monday, 01 September 2025 15:35

In today’s era of rapid technological advancement, our lives are filled with a variety of high-tech products, from smartphones to advanced aerospace vehicles, all of which rely on a high-performance material—tungsten alloy rods—for stable operation. Though you may not often notice it in daily life, it plays a vital role in numerous critical fields.

What Are the Features of Tungsten Alloy Shielding Cans?

- Details

- Category: Tungsten Information

- Published on Saturday, 23 August 2025 15:01

As a critical protective equipment in key fields such as the nuclear industry and medical radiation, the design and performance of tungsten alloy shielding cans are optimized around three core goals: efficient radiation shielding, stable and safe operation, and adaptability to complex scenarios, showcasing numerous unique advantages. Specifically, the key features of tungsten alloy shielding cans include the following:

Uses of Tungsten Alloy

- Details

- Category: Tungsten Information

- Published on Friday, 22 August 2025 19:35

Tungsten alloy is an alloy material made with tungsten as the base, combined with elements such as nickel, iron, and copper. It combines high density, high strength, high-temperature resistance, and radiation resistance. Thanks to its unique physicochemical properties, this material is widely used and plays a significant role in military, aerospace, medical, industrial manufacturing, and other fields.

What Are Tungsten Alloy Blocks?

- Details

- Category: Tungsten Information

- Published on Friday, 22 August 2025 19:29

Tungsten alloy blocks are functional materials made by using tungsten as the base material, with the addition of metals such as nickel, iron, copper, or cobalt, processed through powder metallurgy techniques (including mixing, pressing, and sintering) into solid blocks. They are widely used across industrial, medical, and research fields.

Tungsten Alloy Shielding Cans: the "Protective Umbrella" for Radiation Protection

- Details

- Category: Tungsten Information

- Published on Friday, 22 August 2025 19:24

In modern society, radiation is nearly ubiquitous, emanating from hospital radiotherapy equipment, nuclear power plant operations, radioactive experiments in research institutions, and detection instruments in industrial production—all posing potential harm to human health and the environment. Prolonged exposure to excessive radiation can damage human cells and trigger various diseases. As a result, radiation protection has become a critical concern across multiple fields. Among the various radiation protection methods, tungsten alloy shielding cans have emerged as a "star product" due to their exceptional performance, providing a robust "protective shield" for society.

Heat-Storage Fiber with Cesium Tungsten Bronze

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 August 2025 19:22

Beyond being a key raw material for transparent heat-insulating coatings, films, or glass, cesium tungsten bronze also serves as an important production material for heat-storage fibers, significantly enhancing the comprehensive performance of functional fibers.

Functional Fibers with Nano Cesium Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 August 2025 19:18

As one of the most typical functional fibers, heat-storage fibers can have an appropriate amount of nano cesium tungsten oxide powder added during production as a modifier to further enhance their heat-storage capabilities.

sales@chinatungsten.com

sales@chinatungsten.com