Preparation Process of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:47

- Written by Zhenghua

- Hits: 189

The preparation process of tungsten wire for glass heating mainly involves the purification, processing and subsequent treatment of tungsten materials to ensure that it has excellent performance at high temperatures and is suitable for high-temperature environments such as glass heating. The following is a typical process flow for the preparation of tungsten wire:

1. Raw Material Preparation

Tungsten Ore Purification: The preparation of tungsten wire starts with tungsten ore (such as wolframite or scheelite), and extracts high-purity tungstic acid or tungstate through ore dressing and chemical treatment (such as roasting, acid leaching or alkali leaching).

Tungsten Powder Preparation: Tungsten acid or tungsten oxide (WO₃) is reduced to high-purity tungsten powder by hydrogen reduction. Process conditions (such as temperature and hydrogen flow) need to be strictly controlled to ensure that the particle size of tungsten powder is uniform, and the purity usually needs to reach more than 99.95%.

2. Compacting and Sintering of Tungsten Powder

Pressure Molding: Load tungsten powder into a mold and press it into a tungsten billet (rectangular or cylindrical) under high pressure (usually 100-200 MPa).

Pre-Sintering: Pre-sintering is performed at a relatively low temperature (about 1000-1200°C) to remove volatile impurities and enhance the strength of the billet.

High-Temperature Sintering: High-temperature sintering (about 2800-3000°C) is performed in a hydrogen or vacuum environment to densify the tungsten billet and form a high-strength tungsten rod.

3. Tungsten Rod Processing

Rotary Forging: The sintered tungsten rod is gradually processed into a thinner tungsten rod through a rotary forging machine. Rotary forging needs to be performed at high temperature (about 1500-1800°C) to improve the ductility of tungsten and prevent cracking.

Wire Drawing: The tungsten rod is further passed through a wire drawing die and gradually drawn into a filament at high temperature (about 600-1000°C). Lubricants (such as graphite emulsion) are required during the drawing process to reduce friction, and multiple annealing is performed to eliminate processing stress.

4. Annealing and Surface Treatment

Annealing: The drawn tungsten wire needs to be annealed multiple times in a hydrogen or vacuum environment (about 1200-1500°C) to restore the crystal structure and improve ductility and toughness.

Surface Cleaning: Oxides and impurities on the surface of the tungsten wire are removed by chemical cleaning (such as pickling) or electrolytic polishing to ensure a smooth surface suitable for glass heating applications.

5. Doping Treatment (Optional)

To improve the creep resistance and service life of tungsten wire at high temperatures, trace elements (such as potassium, aluminum, and silicon, called doped tungsten wire) can be doped during the tungsten powder preparation stage. The doped tungsten wire has a more stable grain structure at high temperatures and is often used in heating elements with higher requirements.

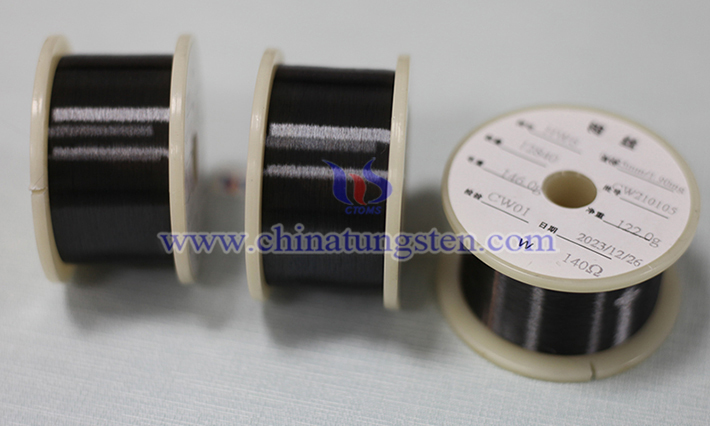

6. Forming and Testing

Forming: According to the needs of the glass heating equipment, the tungsten wire is processed into a specific shape (such as spiral, U-shaped or straight wire) and precise size control is performed.

Performance Testing: Tungsten wire is tested for resistance, tensile strength, high temperature resistance, etc. to ensure its stability and reliability in glass heating environment (usually over 2000°C).

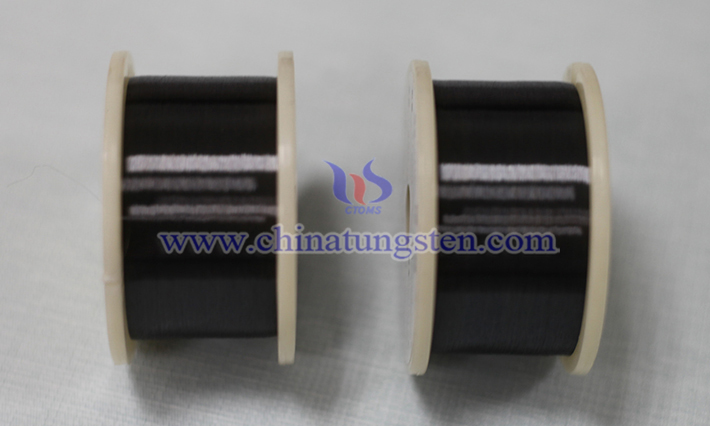

7. Packaging and Storage

The prepared tungsten wire needs to be stored in a dry, oxygen-free environment (such as vacuum packaging) to prevent oxidation and contamination.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com