Production Steps of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:49

Tungsten wire is an ideal choice for glass heating applications due to its high melting point and high temperature resistance. The following is a brief overview of the main production steps for producing tungsten wire for glass heating:

1. Tungsten Ore Extraction and Refining:

Tungsten trioxide (WO₃) is extracted from tungsten ore (such as wolframite or scheelite). Impurities such as sulfur and arsenic are removed through chemical treatment (such as acid leaching and solvent extraction) to obtain high-purity tungsten trioxide.

2. Tungsten Powder Preparation:

Tungsten trioxide is reduced at high temperature (about 600-900°C) in a hydrogen atmosphere to generate metallic tungsten powder. Control the reduction conditions (such as temperature and hydrogen flow rate) to ensure that the tungsten powder particles are uniform and suitable for subsequent processing.

3. Doping and Modification (Optional):

To improve the high-temperature performance of tungsten wire, potassium oxide, silicon, aluminum and other additives can be doped (doped tungsten). Doping helps to enhance creep resistance and high-temperature stability, which is suitable for glass heating needs.

4. Pressing and Sintering:

Tungsten powder is pressed into rod-shaped or block-shaped billets (usually using isostatic pressing technology). Sintering in a high-temperature (about 2500-3000°C) hydrogen or vacuum furnace to form a dense tungsten billet.

5. Forging and Wire Drawing:

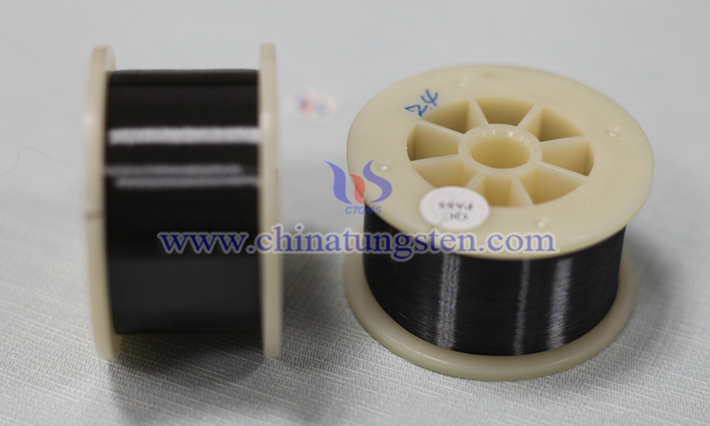

The sintered tungsten billet is heated to about 1500-1700°C and processed into a slender tungsten rod by rotary forging or rolling. Using a multi-pass wire drawing process, the diameter is gradually reduced through the die to make tungsten wire of the required specifications (such as 0.01-1mm). The high temperature (about 1000-1200°C) must be maintained during the wire drawing process, and lubricants must be used to reduce die wear.

6. Annealing:

The drawn tungsten wire is annealed (about 1000-1500°C, hydrogen or vacuum environment) to eliminate internal stress and improve ductility and stability. Annealing process parameters need to be precisely controlled to avoid excessive grain growth.

7. Cleaning and Surface Treatment:

The tungsten wire is cleaned with chemical solutions (such as sodium hydroxide or acid) to remove surface oxides and impurities. Polishing or coating (such as anti-oxidation coating) can be performed according to the requirements of glass heating applications.

8. Cutting and Forming:

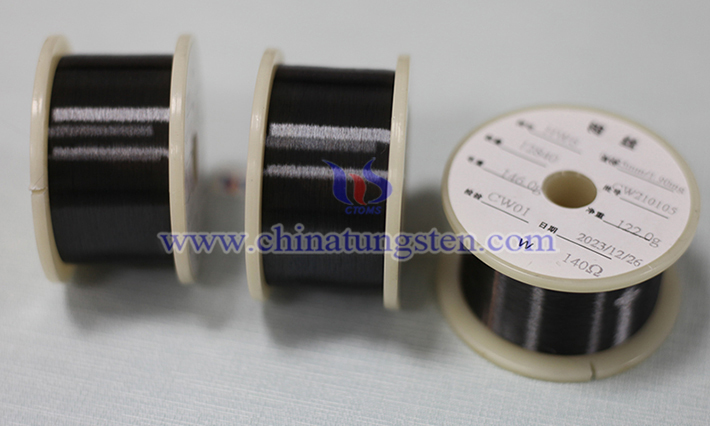

The tungsten wire is cut to the required length, or wound into spiral, wavy and other shapes to adapt to glass heating equipment (such as glass sealing, melting). Ensure dimensional accuracy and consistency.

9. Quality Inspection:

Check the diameter, surface quality, resistivity, tensile strength and high temperature performance of the tungsten wire. Use equipment such as microscopes and tensile testing machines to ensure that it meets the strict requirements of glass heating.

10. Packaging and Storage:

Package in an inert gas or vacuum environment to prevent oxidation. Store in a dry, cool environment, away from moisture and contamination.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com