Disadvantages of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:34

- Written by Zhenghua

- Hits: 162

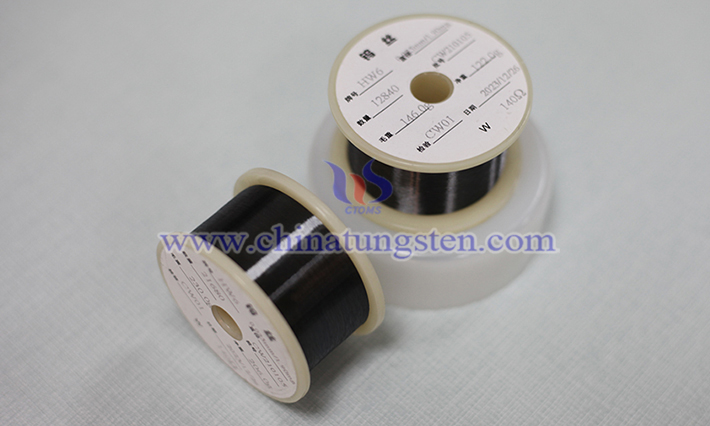

In the glass heating process, tungsten wire is often used as a heating element due to its high melting point, high temperature resistance, and good electrical conductivity. However, despite its excellent performance in some aspects, tungsten wire also has some significant disadvantages in practical applications, which may limit its widespread use in the field of glass heating.

1. Fragility Caused by Brittleness

Tungsten is a metal material with high hardness but high brittleness. In glass heating equipment, tungsten wire may break due to mechanical stress, vibration, or accidental impact. Especially in equipment that requires frequent movement or adjustment, this brittleness can significantly increase maintenance costs and downtime. In addition, although tungsten wire can maintain stability at high temperatures, its mechanical strength will further decrease once it cools, increasing the risk of breakage. Therefore, in glass heating scenarios that require high reliability and durability, the brittleness of tungsten wire becomes a major limiting factor.

2. Stress Issues Caused by High Thermal Expansion Coefficient

Tungsten has a high thermal expansion coefficient, which means that the tungsten wire will experience significant volume changes during the heating and cooling cycles. This thermal expansion and contraction phenomenon may cause mechanical stress inside the heating element, which may cause deformation or cracks. After long-term use, these stresses may accumulate and cause fatigue failure of the tungsten wire. During the glass heating process, the temperature changes frequently, which may reduce the service life of the equipment and increase the frequency of maintenance and replacement.

3. High-Cost Economic Considerations

Compared with commonly used heating materials (such as nickel-chromium alloy or iron-chromium-aluminum alloy), tungsten wire has high manufacturing and processing costs. As a rare metal, the mining and refining process of tungsten is complex and expensive, which directly pushes up the production cost of tungsten wire. In large-scale industrial applications, this high cost may lead to an increase in the overall equipment cost and reduce economic benefits. For projects with limited budgets or cost-sensitive projects, tungsten wire is not the best choice.

4. Safety Challenges Caused by High Voltage Requirements

Tungsten wire requires a higher voltage during the heating process to reach the high temperature required for glass processing. This high voltage requirement not only increases energy consumption, but also may bring potential safety hazards. For example, in certain high humidity or complex environments, high voltage may increase the risk of electric shock or equipment failure. In addition, high voltage equipment also has higher requirements for the power system, and may require additional power support facilities, further increasing the overall cost.

5. Complexity of Processing and Installation

The processing and installation process of tungsten wire is relatively complicated. Due to its hardness and brittleness, tungsten wire requires special processes and equipment during the manufacturing process to ensure that its shape and performance are not damaged. During installation, tungsten wire has a certain sensitivity to the surrounding environment, such as avoiding contact with pollutants or oxygen to prevent oxidation.

Although tungsten wire has disadvantages such as brittleness, high thermal expansion coefficient, high cost, high voltage demand, and oxidation problems, it affects its reliability and economy in practical applications. However, for specific needs, such as special glass processing at extremely high temperatures, tungsten wire is still an ideal choice due to its advantages such as high melting point and excellent conductivity.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com