Tungsten Carbide Rod Properties

- Details

- Category: Tungsten Information

- Published on Monday, 22 September 2014 17:27

- Written by jwy

- Hits: 488

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

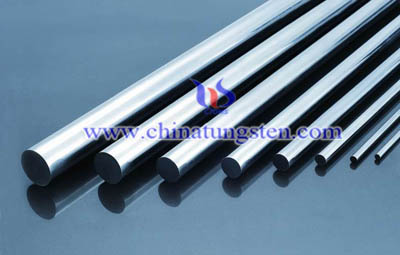

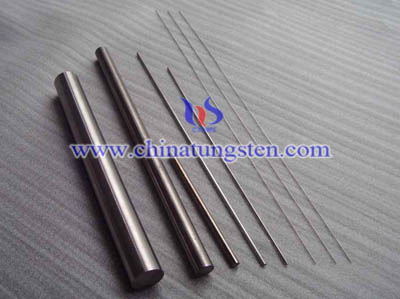

Tungsten Carbide Rods Types

- Details

- Category: Tungsten Information

- Published on Monday, 22 September 2014 17:22

- Written by jwy

- Hits: 553

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Place Fishing Sinkers to the Line 1

- Details

- Category: Tungsten Information

- Published on Monday, 22 September 2014 09:17

- Written by Sherry

- Hits: 582

If you use light bait such as a worm or an insect, you will find that your hook will float at the top of the water and it is difficult to attract any fish. A popular method of getting your hook to submerge further in the water is to use fishing sinkers. These small metal balls are easily placed on the line and increase your chances of catching a fish. So it is critical to place a suitable fishing sinker onto your fishing rigs, it is so easy that you can do it yourself if you have the necessary things, such as fishing line, scissors and sinkers and sometimes you need a snap swivel.

First remove your hook from the fishing line. You will not be able to place your fishing sinkers without a free end of fishing line to utilize. Use a pair of scissors to trim the hook off your line.

Run a line through one of your fishing sinkers. Most style of sinkers have a hole running through the middle of them. This is for securing it to the line. Thread the fishing line through the hole until several inches worth of line are fed out the opposite end of the sinker.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Rod Introduction

- Details

- Category: Tungsten Information

- Published on Monday, 22 September 2014 16:34

- Written by jwy

- Hits: 576

| Type | Diameter (mm) | Dia. Tolerance (mm) | Length (mm) | Length Tolerance (mm) |

| PCB rod | 3.25 ~ 7 | 0 / +0.1 | 12 ~ 40 | 0 / + 0.2 |

| Blank rod | 1.1 ~ 42 | --- | 700 Max | --- |

| rod | 2 .0 ~ 25 | --- | 38 ~ 150 | --- |

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Bar Applications

- Details

- Category: Tungsten Information

- Published on Friday, 19 September 2014 15:50

- Written by jwy

- Hits: 542

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com