Tungsten Disulfide Nanosheet: "Super Helper" in the Energy Field

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 February 2025 17:13

- Written by Xiaoting

- Hits: 307

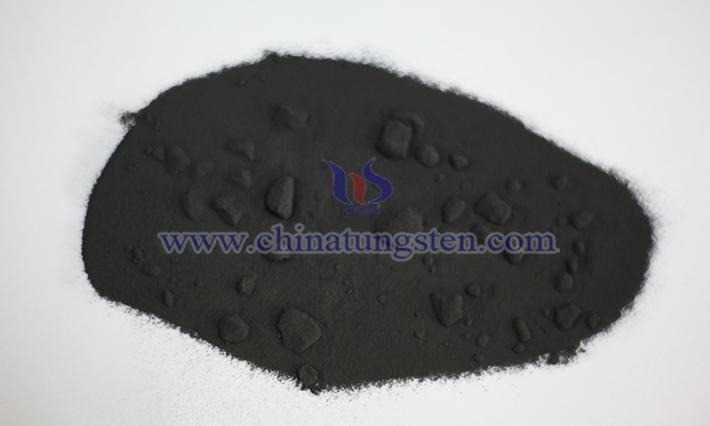

In the world of nanomaterials, the tungsten disulfide nanosheet (WS₂ nanosheet) is gradually becoming a focal point of scientific research. This material is widely used in the energy field due to its unique physical and chemical properties. As global demand for sustainable energy continues to grow, the WS₂ nanosheet offers new possibilities for addressing energy challenges.

Read more: Tungsten Disulfide Nanosheet: "Super Helper" in the Energy Field

Yellow Tungsten Oxide Catalyst: New Material for Green Chemistry Industry

- Details

- Category: Tungsten Information

- Published on Monday, 10 February 2025 17:15

- Written by Zhenghua

- Hits: 362

Yellow tungsten oxide (WO₃), as a novel and highly efficient catalyst, demonstrates remarkable potential in various industrial catalysis fields due to its unique physicochemical properties. It not only possesses excellent photoelectric properties but also plays a crucial role in key areas such as environmental governance and energy conversion, offering new possibilities for the development of the green chemical industry.

Read more: Yellow Tungsten Oxide Catalyst: New Material for Green Chemistry Industry

Yellow Tungsten Oxide Properties and Applications

- Details

- Category: Tungsten Information

- Published on Monday, 10 February 2025 17:05

- Written by Zhenghua

- Hits: 366

Yellow tungsten oxide, with the chemical formula WO₃, is an important member of the tungsten oxide family, appearing as yellow or yellow-green powdered crystals. Its color variation is closely related to its crystal size: it exhibits a bright yellow color when the crystal size is approximately 1.5 micrometers and shifts to green when the crystal size increases to 15 micrometers. Despite the difference in appearance color, its basic characteristics remain consistent.

Read more: Yellow Tungsten Oxide Properties and Applications

Efficient Catalysis: Yellow Tungsten Oxide Leads the Green Revolution

- Details

- Category: Tungsten Information

- Published on Monday, 10 February 2025 17:11

- Written by Zhenghua

- Hits: 351

In today's world where issues of global climate change and environmental protection are increasingly urgent, the scientific and industrial communities are dedicating unprecedented enthusiasm to the research of efficient and eco-friendly catalyst materials. In this journey of exploring green technology, yellow tungsten oxide, this seemingly unremarkable chemical substance, is quietly leading a green revolution with its unique catalytic performance and environmental characteristics.

Read more: Efficient Catalysis: Yellow Tungsten Oxide Leads the Green Revolution

Tungsten Rods: Ideal for High-Tech & Industrial Use

- Details

- Category: Tungsten Information

- Published on Saturday, 08 February 2025 19:20

- Written by Zhenghua

- Hits: 328

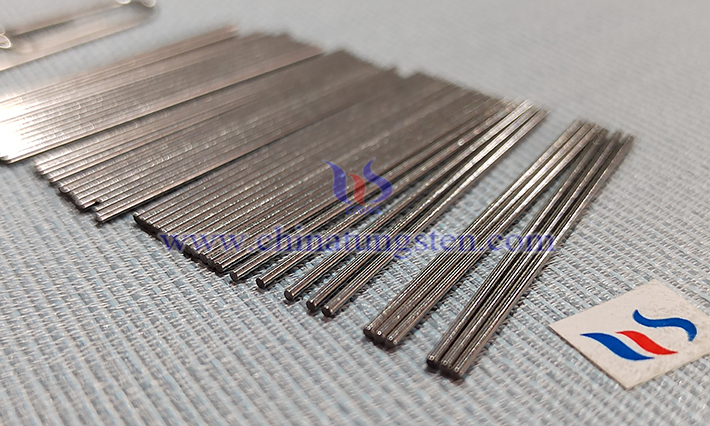

Tungsten rods, with their exceptional properties such as low thermal expansion, outstanding thermal conductivity, superior electrical resistivity, and high elastic modulus, have emerged as the ideal material choice for numerous high-tech equipment and industrial applications.

Read more: Tungsten Rods: Ideal for High-Tech & Industrial Use

sales@chinatungsten.com

sales@chinatungsten.com