Application of Ammonium Metatungstate in Catalyst Field

- Details

- Category: Tungsten Information

- Published on Thursday, 10 April 2025 18:30

- Written by Xiaoting

- Hits: 253

Ammonium metatungstate (AMT), a transition metal compound, is widely utilized in the catalyst field. Whether in catalytic cracking, hydrorefining, olefin epoxidation, or alcohol oxidative dehydrogenation, its unique structure and high activity have driven significant technological advancements, facilitating the efficient production of clean fuels and fine chemical products.

Read more: Application of Ammonium Metatungstate in Catalyst Field

How to Apply Ammonium Metatungstate in Fireproof Fabrics

- Details

- Category: Tungsten Information

- Published on Thursday, 10 April 2025 17:51

- Written by Xiaoting

- Hits: 261

Ammonium metatungstate (AMT) produced by CTIA GROUP LTD is a vital tungsten chemical with application advantages in fire-resistant fabrics, including high flame-retardant efficiency, long-lasting durability, and environmental friendliness. In practical production, AMT, as an effective flame retardant, is scientifically formulated into fabric finishing agents and precisely applied to the fabric surface and interior through processes such as padding or coating. These processes are not only straightforward but also ensure that the flame retardant fully exerts its effects, imparting durable fire-resistant properties to the fabric.

Read more: How to Apply Ammonium Metatungstate in Fireproof Fabrics

What Are the Applications of Ammonium Metatungstate?

- Details

- Category: Tungsten Information

- Published on Thursday, 10 April 2025 17:40

- Written by Xiaoting

- Hits: 302

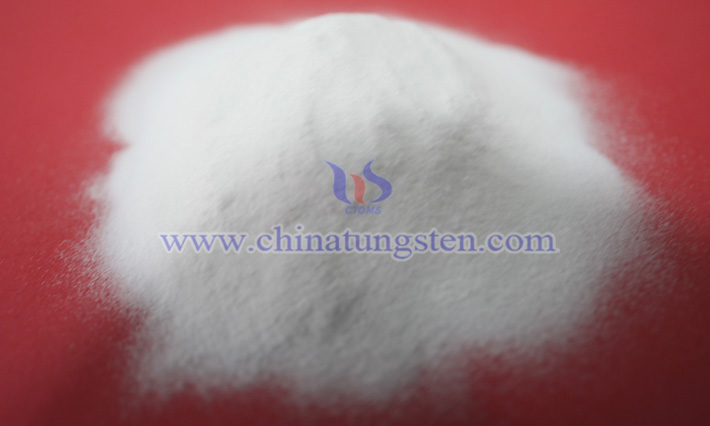

Ammonium metatungstate (AMT) produced by CTIA GROUP LTD is a high-purity white powder renowned for its excellent mechanical, chemical, and thermal properties. It finds widespread application in the preparation of metallic tungsten powder, catalyst production, the fireproofing industry, and the ceramics industry.

Read more: What Are the Applications of Ammonium Metatungstate?

Application of Ammonium Metatungstate in Fireproof Fabrics

- Details

- Category: Tungsten Information

- Published on Thursday, 10 April 2025 17:49

- Written by Xiaoting

- Hits: 273

Ammonium metatungstate (AMT) produced by CTIA GROUP LTD is a significant tungsten compound that can be prepared using methods such as the neutralization method, tungstic acid method, thermal decomposition method, solvent extraction method, and ion exchange method. It is widely applied in fire-resistant fabrics.

Read more: Application of Ammonium Metatungstate in Fireproof Fabrics

Application of Ammonium Metatungstate in Ceramics

- Details

- Category: Tungsten Information

- Published on Thursday, 10 April 2025 17:40

- Written by Xiaoting

- Hits: 274

The application of ammonium metatungstate (AMT), a chemical compound of the transition metal tungsten produced by CTIA GROUP LTD, spans multiple fields. This is because AMT has unique chemical properties and thermal stability. Beyond serving as a crucial precursor for preparing tungsten-based materials, AMT is also a key additive in ceramics. Its roles in ceramics are primarily reflected in the following aspects:

Read more: Application of Ammonium Metatungstate in Ceramics

sales@chinatungsten.com

sales@chinatungsten.com