Production Steps of Barium Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Friday, 11 April 2025 13:52

- Written by Zhenghua

- Hits: 256

Barium tungsten electrode (BaO-W electrode) is a key electrode material used in gas discharge lamps (such as high-pressure sodium lamps and metal halide lamps). Its production steps are as follows:

Manufacturing Process of Barium Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Friday, 11 April 2025 13:44

- Written by Zhenghua

- Hits: 279

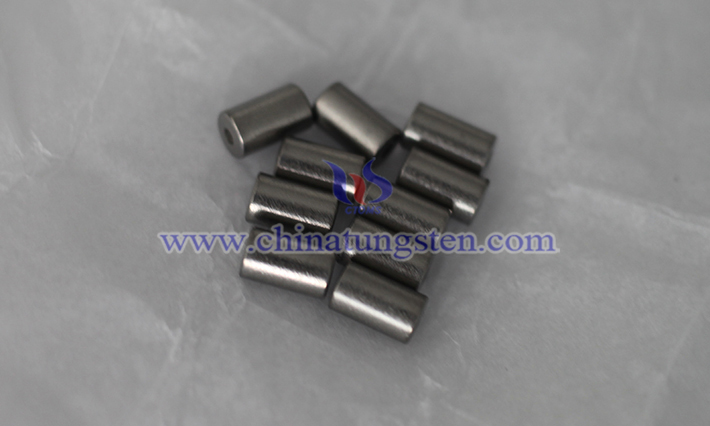

Barium tungsten electrode is a material widely used in electron tube cathodes, and is valued for its good emission performance and stability. The manufacturing process of barium tungsten electrode is mainly based on the impregnation method, which can effectively avoid the problems of barium volatilization and uneven distribution that may be caused by direct mixed sintering. It is a relatively mature and commonly used process.

Read more: Manufacturing Process of Barium Tungsten Electrode

Preparation Process of Barium Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Friday, 11 April 2025 11:49

- Written by Zhenghua

- Hits: 269

The key preparation processes of barium tungsten electrode include porous tungsten matrix, barium impregnation reduction, etc. The following is its main process flow:

I. Preparation of Porous Tungsten Matrix

Preparation of Barium Tungsten Electrode by Impregnation Method

- Details

- Category: Tungsten Information

- Published on Friday, 11 April 2025 13:39

- Written by Zhenghua

- Hits: 252

The preparation of barium tungsten electrode by impregnation is a process commonly used in electron emission materials (such as hot cathodes). By impregnating active barium compounds into porous tungsten substrates, composite electrodes with high-efficiency electron emission performance are formed. The following is a detailed preparation process and key points:

Read more: Preparation of Barium Tungsten Electrode by Impregnation Method

Core Advantages of Barium Tungsten Electrodes

- Details

- Category: Tungsten Information

- Published on Friday, 11 April 2025 11:44

- Written by Zhenghua

- Hits: 255

As a high-performance electrode material, the core advantages of barium tungsten electrode are reflected in the following four aspects:

sales@chinatungsten.com

sales@chinatungsten.com