Tungsten Carbide Composites Containing Alumina Particles and Silicon Nitride

- Details

- Category: Tungsten Information

- Published on Sunday, 08 September 2019 22:30

- Written by meiwei

- Hits: 1373

Traditional cemented carbide is composed of hard WC phase and low melting point metal bonding phase. WC has high hardness, excellent oxidation resistance and corrosion resistance. The addition of metal bonding agent will inevitably weaken the hardness, wear resistance, oxidation resistance and corrosion resistance of the alloy. In addition, it is likely to make the alloy more stable. The decrease of wear resistance, especially the softening and oxidation of metal bond at high temperature, will make WC cemented carbide prone to over-rapid failure, which limits the application scope of WC cemented carbide.

Read more: Tungsten Carbide Composites Containing Alumina Particles and Silicon Nitride

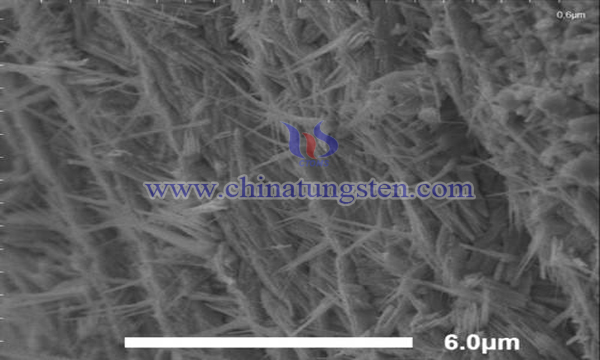

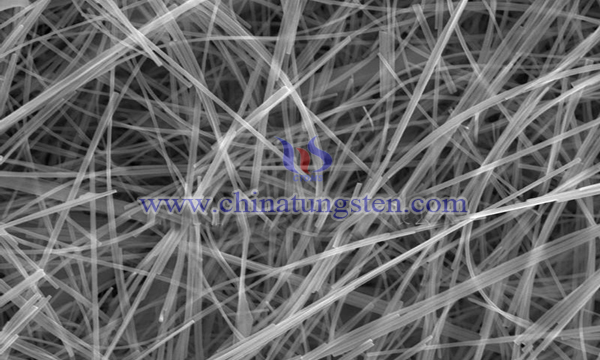

Hydrothermal Synthesis of Tungsten Oxide Nanowires

- Details

- Category: Tungsten Information

- Published on Sunday, 08 September 2019 22:19

- Written by meiwei

- Hits: 1411

Tungsten oxide is a very good catalyst and high temperature superconducting material. It is also used to make electrochromic windows, infrared switches, writing, reading and polishing optical equipment, gas sensitive, humidity sensitive and temperature sensitive components. Meanwhile, tungsten oxide nanowires have excellent field emission properties and can be used as structural precursors for WS2 nanotubes.

Read more: Hydrothermal Synthesis of Tungsten Oxide Nanowires

Cobalt-Tungsten-Nickel-Phosphorus Alloy Electroplating Material

- Details

- Category: Tungsten Information

- Published on Sunday, 08 September 2019 22:05

- Written by meiwei

- Hits: 1356

With the continuous consumption of petroleum resources, the environment for oil exploitation is getting worse and worse, and the requirements for corrosion resistance and friction resistance of petroleum equipment are getting higher and higher. At present, the phenomenon of eccentric wear and corrosion is serious in the field of petroleum machinery. No satisfactory surface treatment technology can be applied to the surface treatment of petroleum machinery, which can simultaneously possess anti-corrosion, wear resistance and low cost.

Read more: Cobalt-Tungsten-Nickel-Phosphorus Alloy Electroplating Material

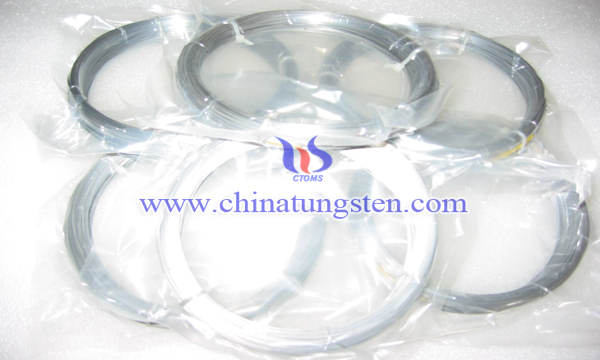

Tungsten-rhenium Alloy Filament

- Details

- Category: Tungsten Information

- Published on Sunday, 08 September 2019 22:11

- Written by meiwei

- Hits: 1379

Tungsten wire is the raw material for making light source materials, high temperature heaters and high temperature resistant components. The traditional production method of tungsten wire is to prepare doped tungsten oxide by adding silicon, aluminium, potassium and other elements into tungsten oxide. The doped tungsten oxide is reduced twice or once by hydrogen at 500-950 ℃, and then doped tungsten powder is obtained by hydrochloric acid, hydrofluoric acid pickling (or not pickling). The doped tungsten powder is pressed by steel mould or isostatic pressing. The doped tungsten bars were obtained by vertical sintering after moulding, and the doped tungsten bars were manufactured by rotary forging and wire drawing.

How to Prepare Polyphenylene Sulfide-Tungsten Powder High Energy Ray Shield Composites

- Details

- Category: Tungsten Information

- Published on Sunday, 08 September 2019 21:54

- Written by meiwei

- Hits: 1321

In recent years, lead-containing materials are being gradually eliminated due to their high pollution, high toxicity, low strength and low efficiency. It is hoped that high-energy polymer composites with good processability will be developed to expand the application of metal materials.

Read more: How to Prepare Polyphenylene Sulfide-Tungsten Powder High Energy Ray Shield Composites

sales@chinatungsten.com

sales@chinatungsten.com