High Purity Coarse Tungsten Disulfide Powder

- Details

- Category: Tungsten Information

- Published on Monday, 25 May 2020 13:38

- Written by Yahong

- Hits: 1678

High purity coarse tungsten disulfide powder refers to tungsten disulfide (WS2) powder with a purity greater than 99.9% and a larger particle size. The specifications of high-purity coarse tungsten disulfide can be WS2 powder with a Fischer particle size F.S.S.S of 1.9 μm and a laser particle size of 15-18 μm; Or WS2 powder with a Fischer particle size F.S.S.S of 3.8 μm and a laser particle size of 20-24 μm; Or a WS2 powder with a Fischer particle size F.S.S.S of 5.0 μm and a laser particle size of 25-28 μm, and so on.

High Purity Ultrafine Tungsten Disulfide

- Details

- Category: Tungsten Information

- Published on Monday, 25 May 2020 13:36

- Written by Yahong

- Hits: 1800

High purity ultrafine tungsten disulfide refers to tungsten disulfide (WS2) powder with purity higher than 99.9% and small particle size. The specifications of high-purity ultrafine tungsten disulfide can be WS2 powder with a Fischer particle size F.S.S.S of 0.4-0.7μm, laser particle size of 3-4μm, or WS2 powder with a Fischer particle size F.S.S.S of 0.8-1.1μm and laser particle size of 9-10μm, etc.

Synthesis of W-Cu Composite Powder by Sintering Ammonium Paratungstate (APT) and Copper Nitrate

- Details

- Category: Tungsten Information

- Published on Sunday, 24 May 2020 19:24

- Written by yuntao

- Hits: 1645

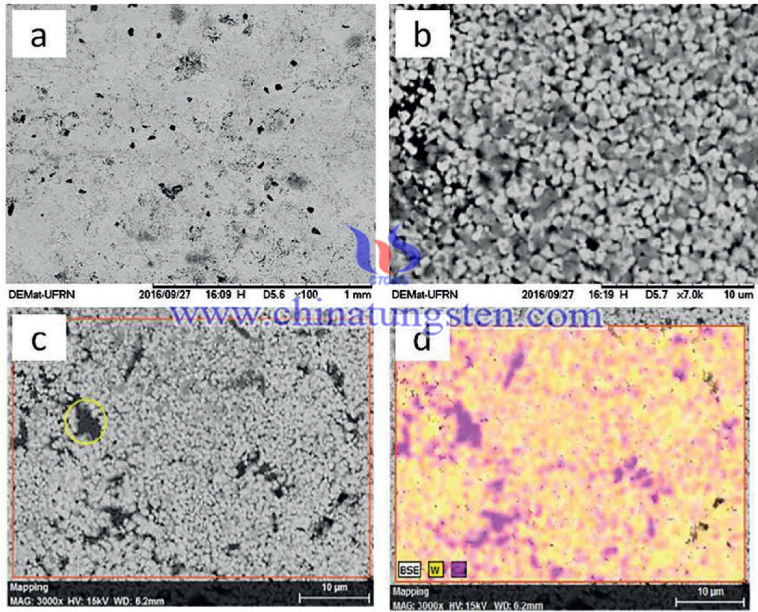

Tungsten and Copper (W-Cu) composite powder has a wide applications in electronics, electromechanical, military, and aerospace and other industries. This is due to its excellent thermal and electrical conductivity. The properties of these powders are dependent on their composition, characteristics of the starting powders and its synthesis procedures.

Plasma Synthesis of Tungsten Carbide Nanopowder from Ammonium Paratungstate (APT)

- Details

- Category: Tungsten Information

- Published on Sunday, 24 May 2020 19:44

- Written by yuntao

- Hits: 1650

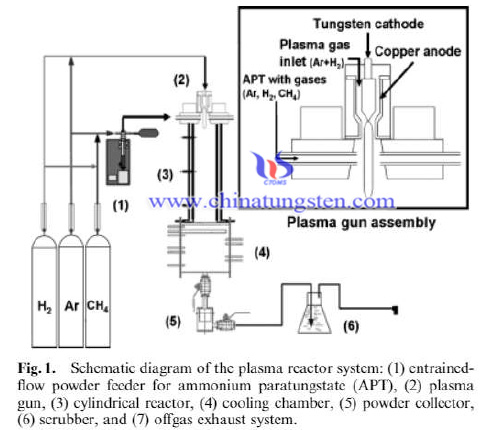

Cemented tungsten carbide (W2C) has attracted great attention due to its properties of high hardness and good wear resistance. It is mostly applied to the metallurgy, drilling, and mining industries under harsh conditions of high-pressure, high-temperature, and corrosive environment. The mechanical properties such as hardness, compressive strength, and transverse rupture resistance depend on the composition and microstructural parameters including the grain size. The reduction in scale of the microstructure also means an increase in the dislocation density and the amount of grain boundaries per unit area.

Read more: Plasma Synthesis of Tungsten Carbide Nanopowder from Ammonium Paratungstate (APT)

Gas-Solid Reaction of Ammonium Paratungstate(APT) to Produce Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Sunday, 24 May 2020 12:49

- Written by yuntao

- Hits: 1723

The main application of tungsten carbide (WC) is the production of hardmetal, or cemented carbide Cemented carbides are composite materials consisting of a hard phase (WC) and a metal, Hardmetal is used for cutting, drilling and wear resistant pieces. Tungsten carbide used for producing hardmetal is conventionally synthesized by heating a mixture of metallic tungsten powder and carbon black in a graphite furnace under a flowing hydrogen atmosphere. The carburization reaction is described as a solid state reaction between W and C. This reaction is re- markably dependent on the diffusion of C in W. There- fore the reaction temperature is high and lies in the range 1400–1800°C. This technique is able to produce WC powders with a wide range of mean particle sizes.

Read more: Gas-Solid Reaction of Ammonium Paratungstate(APT) to Produce Tungsten Carbide

sales@chinatungsten.com

sales@chinatungsten.com