How Is the Anti-Pollution Ability of Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:35

In high-precision welding processes such as tungsten inert gas welding (TIG) and plasma welding, the cleanliness and anti-contamination ability of the electrode has a direct impact on the arc quality, weld consistency and equipment stability.

What Is the Thermal Conductivity of Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:33

In the welding process, the electrode not only bears the functions of arc guidance and electron emission, but also is the key medium for heat transfer. Good thermal conductivity is crucial for electrode life, welding stability and tip temperature control.

What Is the Conductivity of Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:30

In TIG (Tungsten Inert Gas Arc Welding), plasma arc welding and some electronic discharge machining (EDM), the conductivity of the electrode is directly related to arc stability, energy transfer efficiency and welding quality.

How Long Is the Service Life of Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:28

In welding, electrodes are the core material for establishing the arc, conducting energy, and forming the weld pool.

What Is the Arc Starting Performance of Lanthanum Tungsten Electrodes?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:25

In modern welding processes, especially in high-precision applications like TIG (gas tungsten arc welding) and plasma welding, an electrode's arc starting performance is a crucial parameter for evaluating its quality. Arc starting performance directly impacts the smoothness of the welding operation, the quality of the weld's initial formation, and the stable operation of automated welding systems.

What Is the Electron Emission Capability of Lanthanum Tungsten Electrodes at High Temperature?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:23

In welding processes, especially those requiring a stable, high-temperature arc, such as argon arc welding (TIG) and plasma arc welding, the electron emission capability of the electrode plays a central role in the efficiency and quality of the welding process.

What Are the Advantages of Lanthanum Tungsten Electrodes Compared with Pure Tungsten Electrodes?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:20

In high-precision welding techniques like tungsten inert gas welding (TIG), electrodes, as core components for arc generation and energy conduction, play a decisive role in welding performance. Among the many tungsten-based materials, pure tungsten has long been widely used, playing a particularly important role in early welding processes.

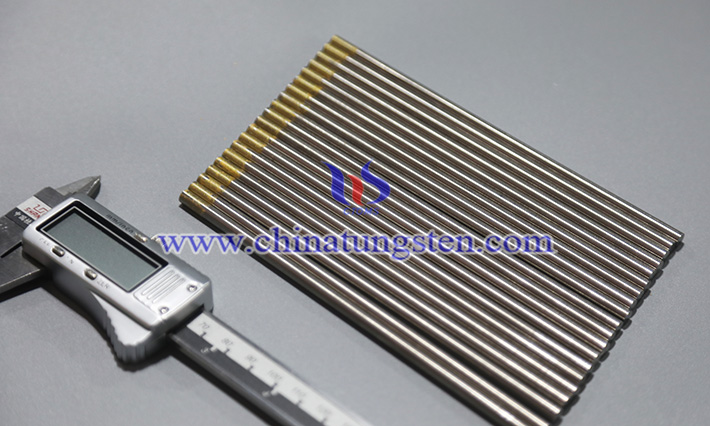

How to Choose the Size of Lanthanum Tungsten Electrode According to the Application?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:17

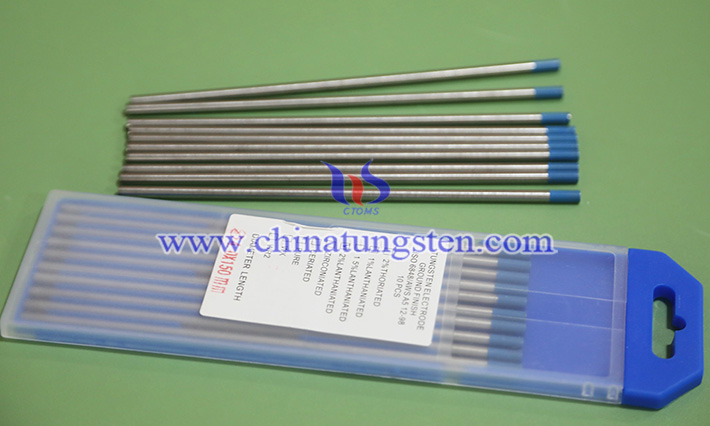

Tungsten inert gas welding (TIG) and plasma welding, the choice of electrode material plays a decisive role in the welding quality. With the widespread application of environmentally friendly materials, lanthanum tungsten electrode has gradually become an important choice in the welding industry.

Which Welding Current Range Is Suitable for Lanthanum Tungsten Electrodes?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:13

In modern welding processes, the correct current setting plays a crucial role in weld quality.

Is the Lanthanum Tungsten Electrode Suitable for Direct Current or Alternating Current?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:11

With the widespread use of argon arc welding (TIG) technology today, the type of welding power source—direct current (DC) or alternating current (AC) —has a direct impact on welding process stability, material compatibility, and welding efficiency. Electrode material, a key component of the welding process, and its compatibility with the power source are fundamental to weld quality.

sales@chinatungsten.com

sales@chinatungsten.com