Tungsten Alloy Multileaf Collimator Model

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 May 2015 18:17

- Written by wenjing

- Hits: 495

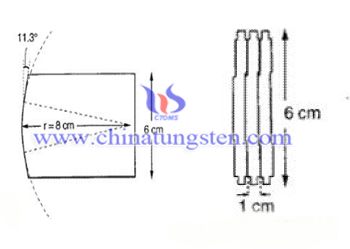

For each multileaf collimator, two banks of independent tungsten alloy leaves face each other and travel linearly perpendicular to the beam central axis. Orthogonal to the direction of motion, the tungsten alloy leaf edge is parallel to the beam ray line from the target. A cross-sectional and front view of the 80-leaf multileaf collimator. All details of the tungsten alloy leaf design were included in the tongue-and-groove used to reduce radiation leakage through interfaces between adjacent leaves and the complex rounded leaf tip.

As the figure below, the central 3 cm portion of each tungsten leaf end is circular with a radius of curvature of 8.0 cm. Beyond this, the tungsten alloy leaf end is straight and at an angle of 11.3° relative to the vertical axis. The multileaf collimator leaf material is a sintered tungsten alloy. These tungsten alloys have densities in the range of 17.0 to 18.5 g/cm3; 17.7 g/cm3 was chosen as a base.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Manufacture Processes of Tungsten Alloy Shielding for Detectors

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 May 2015 18:14

- Written by wenjing

- Hits: 463

Tungsten alloy materials now are widely used to produced as shielding for detectors.the manufacture processesof tungstens alloy shielding for detectors will be the processes of mixing a tungsten alloy power with an organic binder. In comparison to the conventional powder metallurgical fabrication of tungsten and tungsten alloy sheets, producing by pressing, sintering several rolling steps and thermal treatments. The process comprised the mixing of a tungsten alloy powder (such as: with content of 92.5 et.% W and the balance of Ni, Fe) with an organic binder, thermoplastic shaping of mixture to a green sheet material by an extrusion process, followed by debinding and sintering. The sintering step was performed in hydrogen atmosphere under liquid phase sintering conditions at a temperature range of 1450°C to 1500°C. Depend on the different needs of customers,tungsten alloy sheets can be produced into sheets and foils for a thickness range of below 0.1 until 4 mm in collimator.

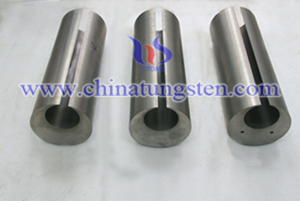

The photograph below shows tungsten alloy materials to manufacture shielding for detectors.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Advantages of Tungsten Alloy Linear Accelerators

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 May 2015 18:09

- Written by wenjing

- Hits: 563

Tungsten alloy products for collimators are widely used in linear accelerators used for radiotherapy treatments. They help to shape the beam of radiation emerging from the machine, they can limit the maximum field size of a beam.

The advantages of tungsten alloy linear accelerators:

Due tungsten alloys have the ability of various high-ray shielding,tungsten alloy can be the good materials for linear accelerators. The thickness 3mm of tungsten alloy can shield 95% of 150keV γ radiation. Tungsten alloy materials are suit for high spatial resolution occasion, such as radiological Imaging array detectors.Tungsten alloy materials has high density, (60% higher than lead), reduces the size of tungsten alloy ray shields, without affecting the radiation shielding effect.Comparing with tungsten alloy and lead, when they with the same performance of radiation shielding, the volume of tungsten alloy is 1/3 of lead .

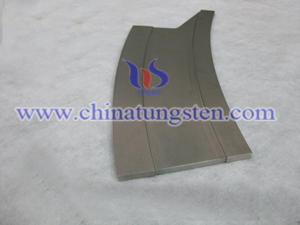

The photograph below shows tungsten alloy materials to manufacture linear accelerators.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Advantages of Tungsten Alloy X-Ray Computed Tomography

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 May 2015 18:12

- Written by wenjing

- Hits: 500

An tungsten alloy X-ray computed tomography (X-ray CT) or computerized axial tomography scan (CAT scan), makes use of computer-processed combinations of many X-ray images taken from different angles to produce cross-sectional (tomographic) images of specific areas of a scanned object.

There are some advances of tungsten alloy X-ray computed tomography:

Due to tungsten alloy materials has high density, (60% higher than lead), reduces the size of tungsten alloy ray shields, without affecting the radiation shielding effect the excellent radiation absorption of tungsten alloy. The sensitive of tungsten alloy X-ray computed tomography is much higher than X-ray computed tomography produced by lead in the limit area.

The environmental friendly characteristics of tungsten alloy, tungsten alloy for radiation detector better than lead for X-Ray Computed Tomography in environmental protection.

The photograph below shows tungsten alloy materials to manufacture linear accelerators.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rod Processing-Extrusion Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 May 2015 17:45

- Written by Cristina

- Hits: 411

Tungsten Carbide Rod Processing-Extrusion Method

The special high wearing resistance, high hardness, excellent toughness and strength, make the tungsten carbide rods being widely used in the metal processing, electronics industry, wood processing, aerospace and medical and other fields. They have been the preliminary materials for manufacturing micro drilling in circuit, milling cutters, reamers, step tools, pole tools, taps and dot matrix printers ideal for needles and other preliminary materials. With the development of technology, demand for tungsten carbide rod is increasing, molding technology developed from the cold isostatic pressing, molding and other traditional techniques to the more modern and economical extrusion molding process. The quality is getting better and there are more and more species.

Tungsten carbide rod extrusion process is the tungsten carbide powder with a quantity of binder, plasticizer and other components of a mixture, extruded through the extrusion die orifice shape and size desired blanks. It is the traditional plastic molding techniques and modern product of the combination of powder metallurgy techniques, used to molding section and length unrestricted shaped pieces, at low temperature, low pressure operation.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com