Research in Machining of Cobalt Alloys and CoCrMo Alloys—Ⅰ

- Details

- Category: Tungsten Information

- Published on Sunday, 16 October 2022 22:18

- Written by Caodan

- Hits: 1195

Research into the processing of cobalt alloys and CoCrMo alloys, which are widely used in manufacturing and aerospace, began a long time ago. Prior to that, all research was focused on improving material properties such as hardness, toughness, strength, wear resistance, corrosion resistance, and high-temperature resistance. Cobalt-chromium-molybdenum alloys are an improved material from the cobalt family and are used in a variety of biomedical applications.

Read more: Research in Machining of Cobalt Alloys and CoCrMo Alloys—Ⅰ

Machinability of Cobalt Chromium Molybdenum Alloys—Ⅱ

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 October 2022 20:43

- Written by Caodan

- Hits: 1271

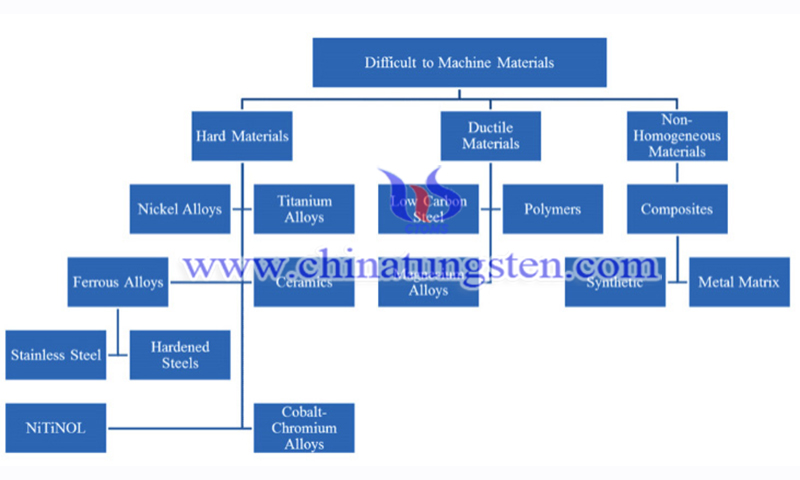

In general, the term machinability can be defined as how easily the material can be machined or cut to the desired shape in terms of tool and process conditions, taking into account surface finish and tool life. The machinability of cobalt chromium molybdenum alloys is comparable to other advanced materials such as nickel and titanium alloys, which are classified as difficult-to-cut materials due to their unique characteristics of high strength, toughness, wear resistance, and low thermal conductivity.

Read more: Machinability of Cobalt Chromium Molybdenum Alloys—Ⅱ

Effect of Zrb2 Addition on 93wt% Tungsten Heavy Alloy

- Details

- Category: Tungsten Information

- Published on Monday, 10 October 2022 21:50

- Written by yuntao

- Hits: 1235

Read more: Effect of Zrb2 Addition on 93wt% Tungsten Heavy Alloy

Machinability of Cobalt Chromium Molybdenum Alloys—Ⅰ

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 October 2022 20:38

- Written by Caodan

- Hits: 1391

Cobalt chromium molybdenum alloys are considered advanced materials and are popular in a variety of engineering and medical applications. However, it is classified as a difficult material to machine due to its unique combination of properties, including high strength, toughness, wear resistance, and low thermal conductivity.

Read more: Machinability of Cobalt Chromium Molybdenum Alloys—Ⅰ

Tungsten Disulfide for Laser Saturable Absorbers Application

- Details

- Category: Tungsten Information

- Published on Thursday, 15 September 2022 21:55

- Written by Caodan

- Hits: 1341

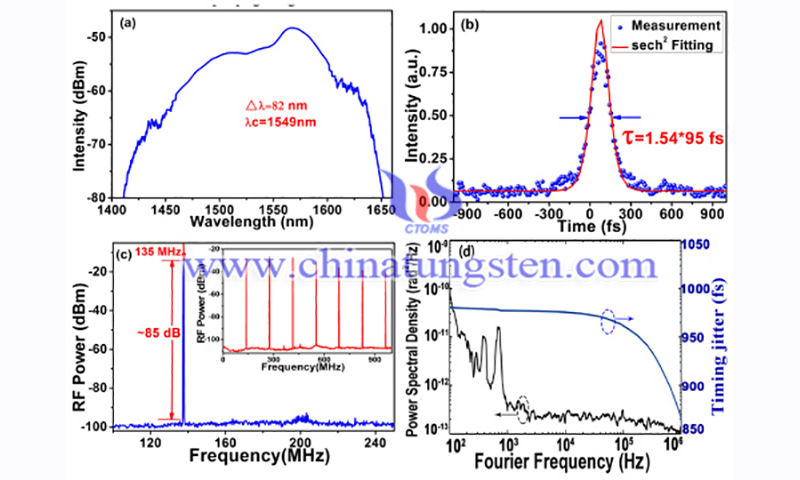

The researchers found that tungsten disulfide (WS2) can be converted into a direct semiconductor with a band gap of 2.1 eV by controlling the chemical composition and number of layers due to the quantum confinement effect. In addition, WS2 has better saturable absorption properties than graphene and carbon nanotubes in the near- and mid-infrared bands. Due to these excellent properties, it is increasingly being used in laser saturable absorbers (SAs).

Read more: Tungsten Disulfide for Laser Saturable Absorbers Application

sales@chinatungsten.com

sales@chinatungsten.com