What Is the Crystal Structure of Ammonium Metatungstate?

- Details

- Category: Tungsten Information

- Published on Monday, 14 April 2025 11:14

Ammonium metatungstate (AMT) produced by CTIA GROUP LTD is a crucial polynuclear tungstate compound with a complex yet highly ordered crystal structure. Centered around a Keggin-type polyoxoanion, it combines with ammonium cations and crystal water to form a stable lattice. This unique structure imparts AMT with exceptional physicochemical properties, making it widely applicable in fields such as catalysts, tungsten materials, and nanotechnology.

Physical and Chemical Properties of Ammonium Metatungstate

- Details

- Category: Tungsten Information

- Published on Monday, 14 April 2025 11:05

Ammonium metatungstate (AMT) produced by CTIA GROUP LTD is a vital tungsten compound widely applied in catalysts, tungsten alloys, electronic materials, and the chemical industry. Its physicochemical properties underpin its unique advantages in industrial production and applications.

What Is the Physical and Chemical Properties of Ammonium Metatungstate?

- Details

- Category: Tungsten Information

- Published on Monday, 14 April 2025 11:01

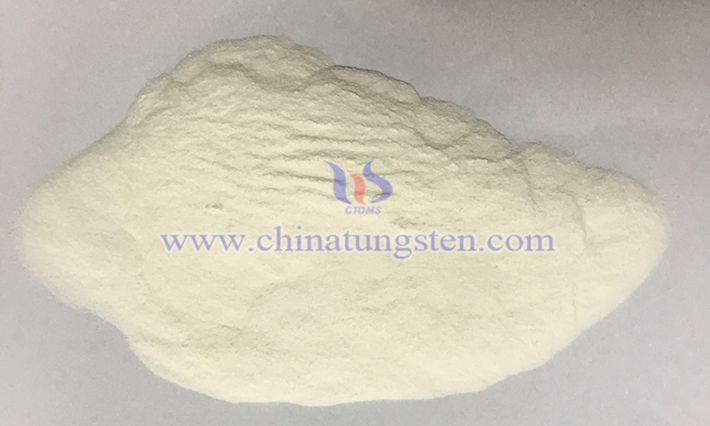

Ammonium metatungstate (AMT) produced by CTIA GROUP LTD is a compound formed by the combination of ammonium cations and metatungstate anions, classified as a composite salt. In appearance, it typically presents as a white crystalline powder, occasionally with a slight yellowish hue, and is widely used in fields such as petrochemicals, electronics, aerospace, and fire-resistant fabrics.

What Is Ammonium Metatungstate?

- Details

- Category: Tungsten Information

- Published on Monday, 14 April 2025 10:58

Ammonium metatungstate (AMT) produced by CTIA GROUP LTD is an inorganic composite salt with the molecular formula H₂₈N₆O₄₁W₁₂, formed by the combination of ammonium cations and metatungstate anions. It appears as a white crystalline powder or slightly yellowish solid. At the microscopic level, its atoms are arranged in an orderly manner through specific chemical bonds, forming a stable chemical structure that endows AMT with unique chemical properties.

Application of Barium-Tungsten Electrodes in the Laser Field

- Details

- Category: Tungsten Information

- Published on Friday, 11 April 2025 14:28

The application of barium-tungsten electrodes in the laser field is primarily attributed to their excellent electron emission performance and high-temperature stability, particularly in gas discharge lasers where they play a critical role. Below is a detailed analysis of their key applications and advantages:

Application of Barium Tungsten Electrodes in Lighting

- Details

- Category: Tungsten Information

- Published on Friday, 11 April 2025 14:26

The application of barium tungsten electrodes in the lighting field mainly focuses on special light sources such as high-intensity discharge lamps (HID lamps), stroboscopes, and xenon flash lamps. Their unique advantages and limitations jointly shape the boundaries of application scenarios. The following analysis combines their characteristics with application scenarios:

Applications of Barium Tungsten Electrodes in the Electronics Field

- Details

- Category: Tungsten Information

- Published on Friday, 11 April 2025 14:23

Barium Tungsten Electrodes have a wide range of applications in the electronics field, primarily due to their combination of barium’s low work function (which facilitates electron emission) and tungsten’s mechanical strength and heat resistance. Below are some of their key application scenarios in the electronics domain:

Application Fields of Barium Tungsten Electrodes

- Details

- Category: Tungsten Information

- Published on Friday, 11 April 2025 14:16

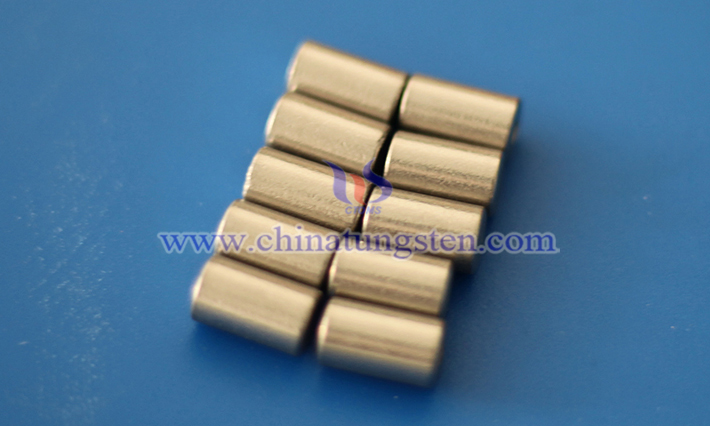

As a high-performance electronic material, barium tungsten electrodes demonstrate wide-ranging applications across multiple critical fields due to their low work function (1.6 eV), high current density (10 A/cm²), excellent ignition performance, and resistance to poisoning. Below are their primary application fields and technical characteristics:

Application Scenarios of Barium Tungsten Electrodes

- Details

- Category: Tungsten Information

- Published on Friday, 11 April 2025 14:12

The Barium Tungsten Electrode is primarily used in specific industrial and technological application scenarios, particularly in fields related to electron emission and high-temperature environments. Below are its common application scenarios:

Role of Barium Tungsten Electrodes

- Details

- Category: Tungsten Information

- Published on Friday, 11 April 2025 14:05

Barium tungsten electrodes are a tungsten electrode material improved through the addition of barium elements. Their core value lies in significantly enhancing electron emission performance, leading to widespread applications across multiple critical domains. Below is a detailed analysis of their functions:

sales@chinatungsten.com

sales@chinatungsten.com