Tungsten Alloy Weight Throw

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 July 2013 16:21

Traditional weight throw was made by iron or lead but tungsten alloy weight throw is more and more popular because of its advantages such as high density, high melting point, small volume, excellent hardness, superior wearing resistance, high ultimate tensile strength, high ductility, high temperature resistance, etc. Tungsten alloy is a perfect material to make weight throw especially to make the sphere.

The high density of tungsten alloy can improve the speed and length when throwing, in this way, tungsten alloy weight throw can help the competitors to catch a high score. Non-toxic and environmental friendly of tungsten heavy alloy is another advantage for tungsten heavy alloy to make tungsten alloy weight throw. It is the durable material and can be used recycling. Tungsten heavy alloy is also very easy to machine, the manufacturer can save a lot of time in the processing of making tungsten alloy weight throw. Tungsten heavy alloy has strong wind resistance, when the match is held in a windy day; the wind can has little bad influences for the match if the weight throw was made by tungsten alloy. Good corrosion resistance is another advantage for tungsten heavy alloy to make weight throw, after using a lot of times by different competitors, weight throw cannot be eroded by the users sweat.

Because the density of tungsten is higher than steel, iron and lead. So compared with the tungsten alloy weight throw, the weight throw made of steel, iron or lead are larger than the tungsten alloy weight throw, which make them not convenient to throw, and compared with the tungsten alloy material, they have larger air resistance. On the other hand, the tungsten alloy weight throw has better directionality when it is thrown by the athlete. In a word, tungsten alloy weight throw can help to improve the scores, so tungsten alloy is the best choice in the match.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Plasma Technique Treatment – Endless Possibilities

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 July 2013 11:04

Tungsten alloy plasma technique can be used in many different cases whenever you would like to better adhere materials together or to change a surface property to suit your needs. With this trend-setting technology it is possible to modify virtually any surface. tungsten alloy plasma technique offers several versatile applications, for example:

Cleaning surfaces of any residues, oils, or contamination

Activation of various materials before gluing, painting, etc.

Etching and partial removal of surfaces

Coating of parts with several possible types of layers (PTFE-like, protective barriers, hydrophobic, hydrophilic, friction-reducing, etc.)

Tungsten alloy plasma technique is establishing itself in all areas of industry, and new applications are constantly evolving.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Low-pressure Tungsten Alloy Plasma Technique

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 July 2013 10:54

For the technical realization of low-pressure plasma processes, one requires equipment with the following components:

Vacuum system (pump, vessel)

Energy supply

Gas supply

Measurement and control components for the reproducible adjustment of the process parameter

Due to the necessity of a vacuum system in most cases, batch operation method is the easiest solution. The processes can be flexibly and complexly configured, in order to change the mode of action of the tungsten alloy plasma technique through variation of the process parameters (pressure, gas flow, gas composition, power) and can attain different effects in one process step. So that, i.e. without great expenditure a secondary cleaning can be carried out and immediately thereafter a corrosion protection layer becomes deposited, without having to aerate in between.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

What Is Tungsten Alloy Plasma Technique?

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 July 2013 10:46

Applications which might gain more importance in the future are construction material for the tungsten alloy plasma technique in magneto hydrodynamic power generation (W and W-Cu) and target plates in fusion reactors (W, W-La2O3).

Recent tungsten alloy plasma technique and theoretical and numerical studies show that tungsten may be the best, if not the only, material to withstand the extraordinary operating conditions in a nuclear fusion reactor diverter. The diverter, being that part of the vacuum vessel where the tungsten alloy plasma technique particles interact with the first wall, and where a large fraction of the fusion heat is removed, consists of water-cooled copper heat-exchanger element covered with a plasma facing armor. The tungsten alloy plasma technique particles (electrons, protons, and α-particles) are directed by the magnetic field toward the diverter target plates, where they are neutralized and pumped. The convective heat flux reaches 20 MW.m-2 and the attendant surface temperature more than 3000℃. Therefore, a suitable armor material must have a high thermal conductivity (in order to transfer high heat fluxes), low thermal expansion coefficient and low Young's modulus (in order to keep thermal stresses low), and a high melting point and low sputtering yield (in order to keep erosion low). Although tungsten does not have as high a thermal conductivity and as low a Young's modulus as carbon-carbon composite materials, which are foreseen for the sections of the diverter with the highest heat flux, many experts believe that, in the long run, reasonable lifetimes will only be achieved by tungsten diverter plates, which have the lowest erosion rates of all materials in sections of the diverter with relatively low plasma temperature but high particle density.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Ignition Tubes for Rocket Engine

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 July 2013 10:28

A rocket engine tungsten ignition tubes or simply "rocket" is a jet engine that uses only propellant mass for forming its high speed propulsive jet. Rocket engines tungsten ignition tubes are reaction engines and obtain thrust in accordance with Newton's third law. Since tungsten ignition tubes need no external material to form their jet ignition tubes, rocket engines ignition tubes can be used for spacecraft propulsion as well as terrestrial uses, such as missiles. Most rocket engines ignition tubes are internal combustion engines, although non combusting forms also exist.

Rocket engines produce thrust by the expulsion of a high-speed fluid exhaust. Tungsten ignition tubes fluid is nearly always a gas which is created by high pressure (10-200 bar) combustion of solid or liquid propellants, consisting of fuel and oxidizer components, within a combustion chamber.

Because of its superior wear resistance, high melting point, low vapor point and strange hardness, tungsten alloy is increasingly used to manufacture ignition tubes of rocket engines.

In rockets, temperatures employed are very often far higher than the melting point of the nozzle and combustion chamber materials. Tungsten ignition tubes in rocket engine can overcome this problem; two exceptions are graphite and tungsten (~1200 K for copper). It is important that tungsten ignition tubes be prevented from combusting, melting or vaporizing to the point of failure. Properly manufactured and corrosion shielded tungsten alloy parts will increase safety of any rocket usage.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Usage of Tungsten Alloy Armor Piercing Bullet

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 July 2013 10:11

The most widely used tungsten alloy armor piercing bullets in the world are made of a hardened steel, tungsten alloy, tungsten-carbide, or depleted uranium penetrator enclosed within a softer material, such as copper or aluminum. Tungsten alloy rounds, for instance, take advantage of their high-density material, designed to retain its shape and carry the maximum possible amount of energy as deep as possible into the target.

The tungsten alloy armor piercing bullets fired from rifles are strengthened with a copper orcuprous-nickel jacket, much like the jacket that surrounds lead in a conventional projectile, a jacket which is destroyed upon impact to allow the penetrating charge to continue its movement through the targeted substance.

One of the most famous types of tungsten alloy armor piercing bullets used in the past was the Teflon-coated bullets. Contrary to popular belief, the Teflon coating did not in itself help the bullet penetrate deeper, instead it was meant to help reduce the wear on the barrel after firing hardened projectiles. The strange fact is that this misconception even produced laws that lead to the restricted use of these bullets, eventually leading to their extinction.

The famous example of such a blunder was the assassination attempt on US President Ronald Reagan that took place on March 30, 1981. Then, the shooter used an tungsten alloy armor piercing bullet with a normal revolver, which actually deprived the bullet of its ability, contributing to the bullet missing the heart by less than one inch and piercing his left lung instead, which likely spared his life.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Characteristics of Tungsten Alloy Armor Piercing Bullet

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 July 2013 10:00

Shells of the tungsten alloy armor piercing bullets are designed for this purpose have a greatly strengthened case with a specially hardened and shaped nose and a much smaller bursting charge. Some smaller caliber tungsten alloy armor piercing shells have an inert filling, or incendiary charge in place of the HE bursting charge.

Tungsten alloy armor piercing bullets are famous for their ability to penetrate target.It is mostly because large kinetic energy and their high tensile strength focused on the target. Tungsten alloy armor piercing bullets are made from the high-density tungsten alloy that is much harder than most armors. All have a very hard tungsten alloy armor piercing warheads.Tungsten alloy armor piercing bullets can be used against tanks, armored vehicles and concrete fortifications. When fired, tungsten alloy armor piercing bullets are under the high-temperature, high-pressure gas. Reach the target, it will make a pit in the surface of the armor, red out the armor and the pit bottom at the same time. At this time, although the head has been broken, missile force the powerful impact of inertia, it will continue onrush. When the impact force reaches a certain value, the fuse is triggered, it caused the explosion of the projectile charge. At this time, exploding charge will create tons of pressure per square centimeter in area, killing the crew inside the tank or destroying armored weapons.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

What Is Tungsten Alloy Armor Piercing Bullet?

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 July 2013 09:43

Tungsten alloy armor piercing bullet relys on the kinetic energy of the projectile, penetrates armor and destroys the target. Its characteristic is high velocity, long hitting the distance and good accuracy.It used for mutilate tanks, self-propelled guns, armored vehicles, ships, aircraft, or any other armored target.

Tungsten alloy armor piercing bullet is a type of ammunition designed to penetrate armor and detonate. They are generally used against body armor, vehicle armor, tanks and other defenses, depending on the caliber of the firearms.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Basic Knowledge of Tungsten

- Details

- Category: Tungsten Information

- Published on Monday, 15 July 2013 10:45

Tungsten is silvery white metal, melting point is as high as 3400℃; High hardness, high density, high temperature strength. Tungsten are mainly used for the production of iron and tungsten carbide. Tungsten, molybdenum, cobalt and chromium and other components of the heat resistant alloy used to make tools, metal surface hardening materials, with blade drawing machine. With tungsten, molybdenum, tantalum, niobium fusion of gold to. Tungsten copper and silver tungsten alloy used to make the light bulb, the tube parts and electric arc welding electrode. Some of the compounds can be tungsten fluorescent agents, pigment, dye, etc.

Tungsten is widely used in petroleum and natural gas, mining, electronic, metal processing, machinery and equipment, heavy manufacturing, the department that the application of tungsten to 85% of the total, other applications in military, nuclear energy and aerospace industry, etc. With the development of economy, the progress of science and technology of China's tungsten, application scope is gradually expand, to increase, and great varieties of products to meet the national economic construction and the needs of the construction of national defence and military affairs.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

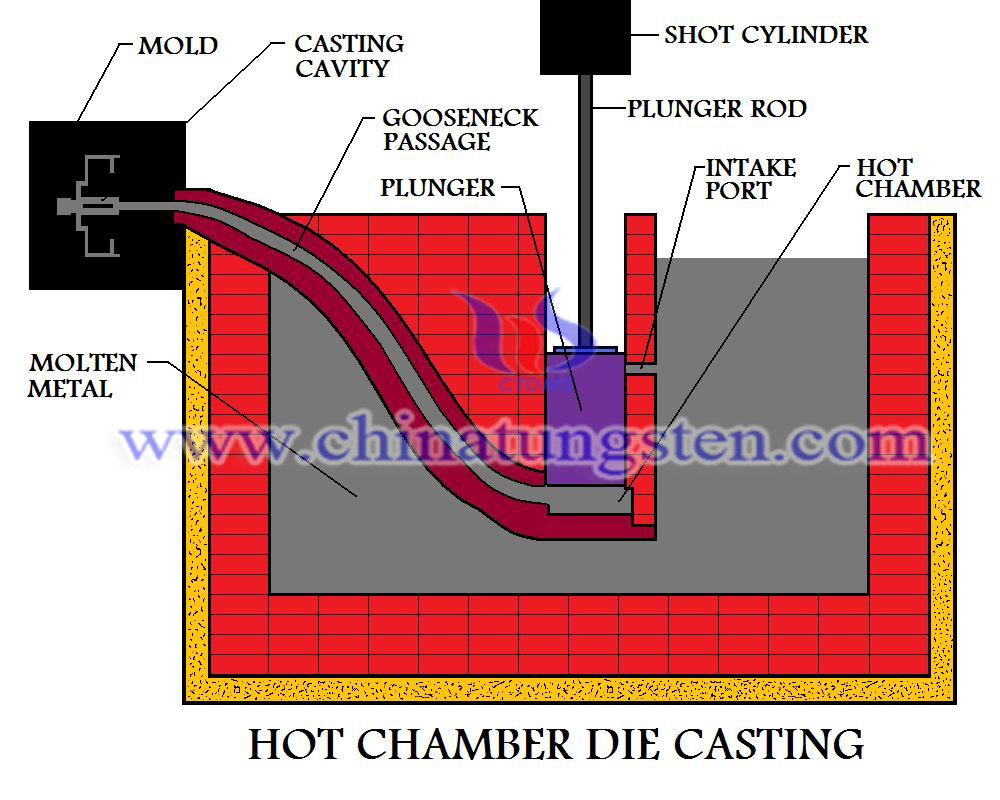

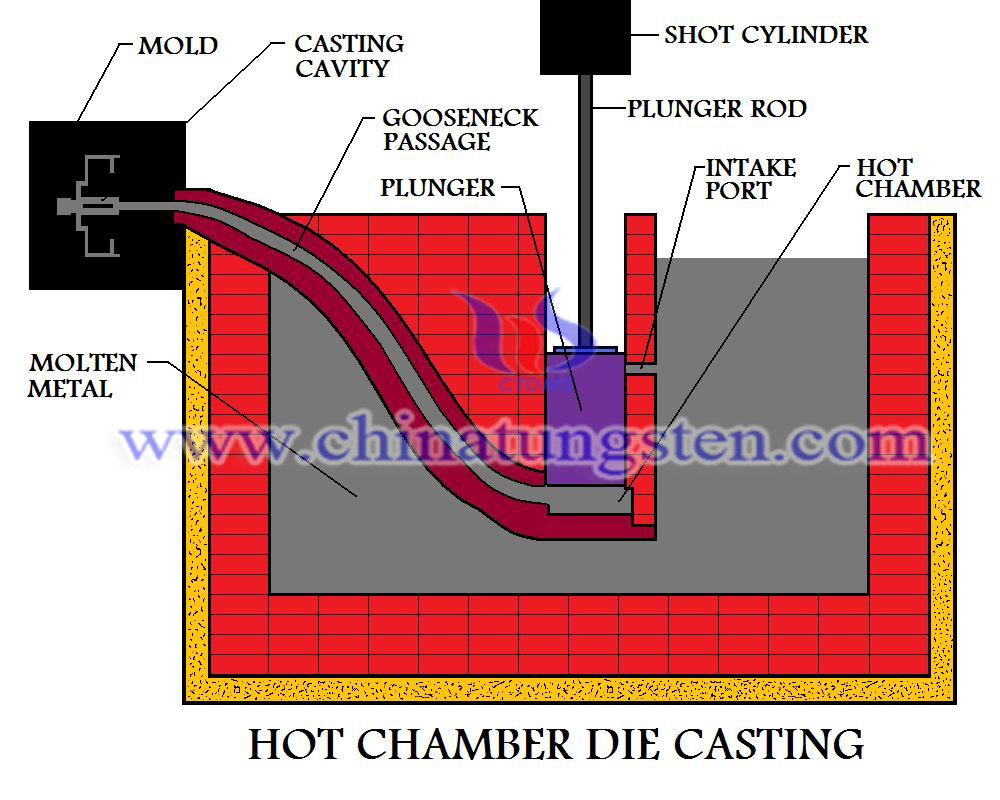

Tungsten Alloy for Die Casting

- Details

- Category: Tungsten Information

- Published on Monday, 15 July 2013 10:35

Hard steel production is usually suppressed by a solid metal hole, known as the mold, in such a high-intensity pressure, as it is squeezed out like noodles. Can you imagine how much this incredible hole kind of power? In some cases, will use the diamond or sapphire (similar hardness) die, but die casting, made of tungsten alloy is still very high intensity, even at very high temperature.

Because of its heat resistance, high hardness, high toughness, tungsten alloy is very suitable for production of die casting, components, etc., particularly to suppress copper alloy, aluminum, zinc, brass. Die casting is made of tungsten alloy, high melting point, not oxygen (except in the case of impure).

As the tungsten alloy is very strong, which also ensures it a longer life than the traditional mold, but also to ensure minimum shrinkage porosity. Therefore made of tungsten raw materials such as the die casting to ensure product quality and high standards

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com