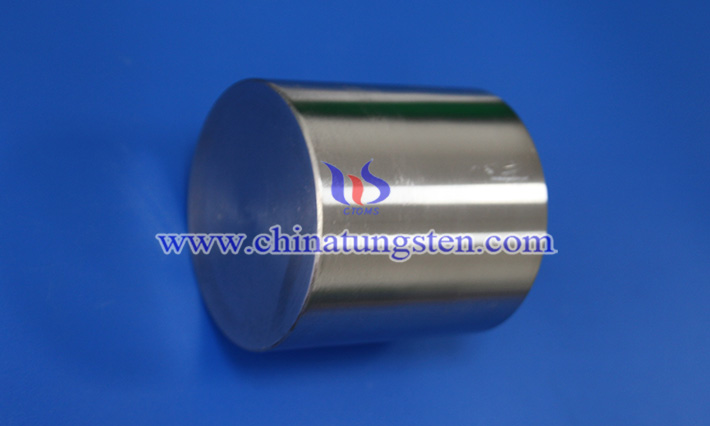

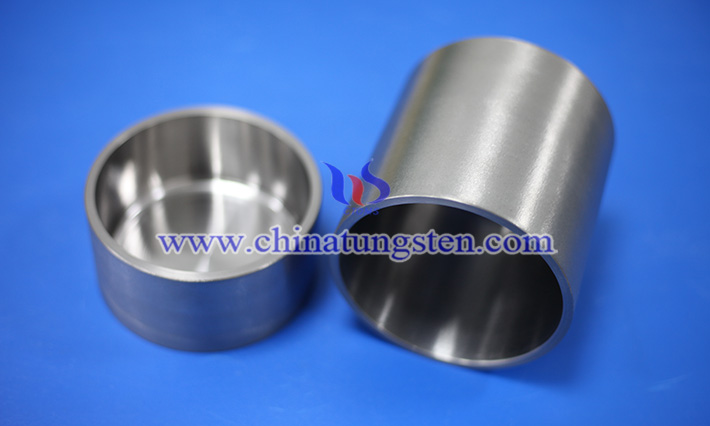

How to Prevent Tungsten Crucible from Cracking?

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:36

In the actual use process, tungsten crucibles often face the risk of crack formation, which not only affects its service life, but also directly affects the stability of the process and product quality.

Therefore, how to effectively prevent the formation of cracks has become the focus of the industry. In this paper, we will systematically discuss the strategies to prevent crucible cracks from the aspects of material selection, processing technology, use environment and operating procedures.

First and foremost, material purity and quality control are fundamental to the prevention of crack formation. The high-purity tungsten powder raw material helps to reduce internal impurities and grain boundary defects, and improves the overall compactness and uniformity of the crucible. The presence of impurities can easily become the stress concentration point of cracks, and it is easy to lead to crack initiation and propagation during high-temperature thermal cycling. Therefore, in the powder metallurgy preparation process of crucibles, strict control of raw material purity and sintering process to ensure that the product is dense and porous, is a key step in crack prevention.

Secondly, optimizing the machining process is essential for crack prevention. Tungsten material itself is brittle and hard, and it is prone to mechanical stress and micro-cracks during processing. The use of CNC precision machining, reasonable cutting parameters and multi-stage polishing process can significantly reduce surface defects and stress concentrations. In addition, the smoothing of the inner wall not only improves heat transfer efficiency, but also reduces the risk of stress concentrations and crack initiation due to surface roughness.

In addition, reasonable heat treatment and thermal cycle management are important links to prevent the formation of crucible cracks. When working at high temperatures, tungsten crucibles undergo many heating and cooling, and if the temperature changes too quickly, it is easy to lead to thermal stress concentration, resulting in thermal fatigue cracks. Therefore, the slow and uniform temperature rise and fall rate, combined with the scientific heat treatment process, can effectively release the internal stress of the crucible, which can greatly reduce the probability of thermal cracking. At the same time, avoiding quenching and heating and sudden temperature changes is an effective measure to prolong the life of the crucible.

In addition, the control of the use environment also has an important impact on the prevention and control of crucible cracks. During high-temperature operation, avoid contact with reactive gases such as oxygen and water vapor to reduce material embrittlement caused by oxidation and corrosion. A high-quality vacuum or inert atmosphere environment can effectively protect the crucible surface from surface defects caused by chemical reactions, reducing the chance of cracking.

Finally, standardized operating procedures and routine maintenance cannot be ignored. Operators should strictly adhere to the equipment heating curve and maintenance schedule, regularly check the surface and structural integrity of the crucible, and detect microcracks and damage in time. Reasonable use frequency and load conditions to avoid overload operation are the basis for ensuring the long-term stable operation of tungsten crucible.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com