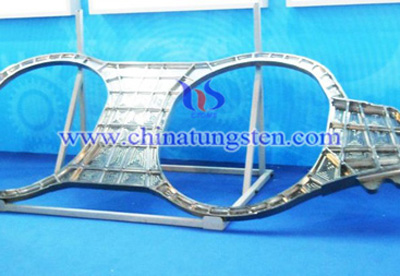

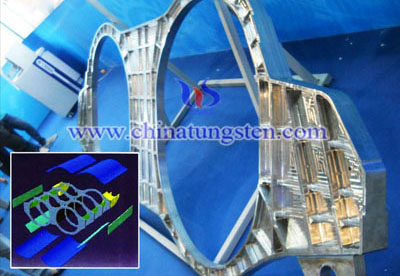

Chinese New Military Fighter/Aircraft Is Made From Titanium Alloy Parts

- Details

- Category: Tungsten's News

- Published on Thursday, 04 September 2014 09:12

As the characteristics of high strength, wide temperature range (-269℃~600℃), good corrosion resistance and process ability, titanium alloy has been widely used in aerospace and structure of engine. In recent years, with the rapid development of the world titanium industry, there are 50% of market share belonging to aviation industry. New titanium alloy in the specified structure can resist damages including defects, cracks or others in its service cycle.

Chinese titanium industry has developed quickly in recent years, titanium production has been ranked the fourth largest in the world, but titanium alloy products using in aviation structure (semi-finished products such as forgings and big bars) only accounts for 10%, so there is a long distance to the world level. Therefore, it is necessary to strengthen technology and application research of titanium alloy material using in aviation structure. Setting up titanium alloy materials system with Chinese characteristics is an important force and guarantee to increase the dosage of titanium alloys in aviation industry.

Just as the chairman of AVIC, Lin Zuoming said that the key to cast a sword is materials when he talked about Beijing Institute of Aeronautical Materials. As the chief technical expert on titanium alloy material technical in AVIC, Dr. Zhu has achieved the main key of titanium alloy materials in our country based on domestic and independent guarantee with his research team, which is the first time to get rid of long-term dependence on titanium alloy from Russia and America.

He has created TC21 and TC4-DT titanium alloy material, as well as application technology of titanium alloy material and TB8 application technology, which has made an important contribution to the development of titanium alloy material, forming a titanium alloy material system with Chinese characteristics. In the beginning of 2012, the scientific and research projects launched by Zhu has been won the second prize of national scientific and technological progress, and Zhu has been interviewed by Party and state leaders.

For example, through material and technology innovation, TC21 titanium alloy has the characteristics of high strength, high toughness, anti-embrittlement, good welding performance, and damage tolerance at an organic whole, whose comprehensive performance level leads in the world. At the same time TC4 - DT titanium alloy has the advantage of medium strength, high toughness, good welding performance, damage tolerance and others. Compared with the similar foreign material, it has more excellent comprehensive performance, and gets the popularization and application, has realized the aircraft titanium alloy from imitation to innovation, from the static strength to the damage tolerance, from a single performance to the comprehensive performance.

Zhu's not only embodies in researches, but also an expert for the application. He put forward two patent technologies, which formed a new generation application technology system of aircraft with high damage tolerance type titanium alloy series in China. He used to say that technological innovation does not mean research entirely in the laboratory, but should be combination with factory and actual application, thus forming the integration of industry-university-research. There is more than half of the year spending in going to and from each aircraft factory, forging factory and factory for Zhu, he has combined his innovative research results with actual, implement innovative applications.

By exploring a new research pattern of aviation materials, Zhu has opened up a research and engineering application model of main building materials with his research team. By presiding the material special projects of “Ninth Five” pr-research, “Tenth Five” pre-research and “Eleventh Five” pre-research, Zhu has chosen titanium alloy material as the breakthrough point on the basis of the authority of decision-making and aviation industry development requirements, and has set up a research and engineering application model with the advantages of low cost, short cycle and good effect. Going by the principle of the whole process of material research and application, Zhu has filled a gap from technology research to engineering application, quickly improved the maturity of backbone material technical in order to give a reliable technology support to engineering and model application.

In fact, alloy related to titanium, tungsten, molybdenum such as tungsten molybdenum alloy, TZM alloy, etc. are widely used for F13, F15, F17, F18 military fighter recently as for its high properties such as high melting point, high strength, wearing resistance, etc.

Dr. Zhu Zhishou, born in 1966, is a researcher and the chief technical expert of Beijing Institute of Aeronautical Materials of AVIC ( in short for Aviation Industry of China ) Dr. Zhu, who has been engaging in basic research and applied research on aviation with titanium alloy since 1991, has launched and completed 10 national key scientific and technological projects, 3 technological research projects and 6 other projects in hand with his endless innovative ability. Besides, Zhu has ever been awarded the second prize of National Scientific and Technological Progress, the first prize and third prize in National Defense Science and Technology Progress, and has ever published over 70 research papers. What's more, he has owned 2 patents authorized by national invention and 1 patent authorized by the Ministry of National Defense, and has declared 7 national invention patents with the award of aviation contribution.

Zhu has promoted to establish the management innovation mechanism, and given full play the team spirit of "solidarity and collaboration, set intelligence to overcome difficulty", and cultivated young backbone strength, relying on experts in major nodes for technical controlling. To carry our fine management according to the contract, and strengthen supervision, and be ensure research unit adopts the method of system engineering, according to the contract, the implement of fine management review and strengthen the node process supervision, to ensure material development and application.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com