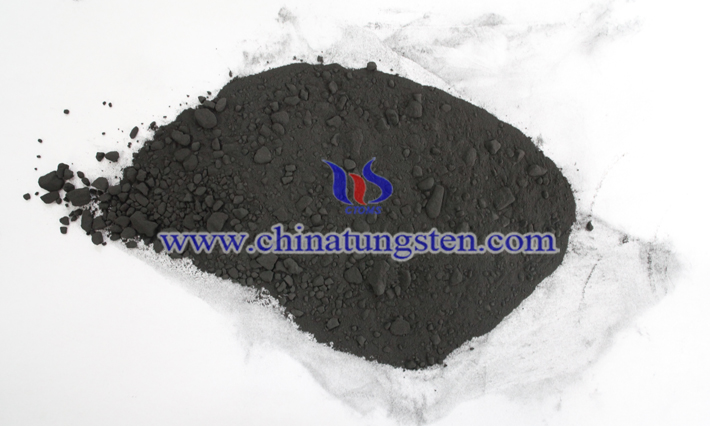

Preparation Method of High Crystallinity Tungsten Carbide Powder

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 September 2020 16:34

Tungsten carbide-based cemented carbide is widely used in cemented carbide, and high-quality tungsten carbide powder is the basis for preparing high-performance cemented carbide. What is the preparation method of high crystallinity tungsten carbide powder?

A preparation method of tungsten carbide powder with high carbonization crystal integrity and fast carbonization rate includes the following steps:

1) After mixing tungsten powder and carbon black, press the compact into a compact by a press; 2) Carburize the compact in step (1), after the carbonization is completed, ball milling and sieving can obtain high crystallinity tungsten carbide powder.

Precautions for this preparation method:

1. In step (1), the F.S.S.S. particle size of the tungsten powder is 3-40μm, and the particle size of the tungsten powder is too fine and it is not easy to form during pressing. The pressing pressure of the press is 1.0-2.0mpa. The mixing is ball mill mixing, and the mixing time is 1~6h.

2. In step (2), the carbonization temperature is 1500-2500°C. As a preference, when the tungsten powder's F.S.S.S. particle size in step (1) is 3-13μm, the carbonization temperature is 1500-2000°C. When the particle size is greater than 13μm, the carbonization temperature is generally 2000-2500°C.

3. In step (2), the carbonization should be carried out in a vacuum, inert gas or hydrogen atmosphere. The carbonization time is 1 to 6 hours, preferably 2 to 4 hours. The ball milling time is 0.5 to 4 hours. The sieving is twice sieving, the first sieving, the sieve mesh is 100-264 mesh, the second sieving, the sieve mesh is 60-180, the second sieving sieve aperture is larger than the first time.

The principle of the preparation method: in the process of producing tungsten carbide powder, the main function of using a press to press the mixture of tungsten powder and carbon black into a compact includes the following aspects: (1) The compacting effect makes the carbon black particles and the tungsten powder particles close together, and shortens the carbonization reaction distance. (2) Thermal insulation, make full use of the exothermic heat of the carbonization reaction to increase the speed of the carbonization reaction. (3) Forming function, the massive tungsten carbide does not need to be pre-crushed, directly enters the next ball milling process. (4) Isolation. There is no surface penetration of tungsten powder and carbon black compacts and sintering vessels during the carbonization process, which eliminates the surface dirty phenomenon in the traditional carbonization process and improves the quality of tungsten carbide.

Compared with the tungsten oxide reduction-carbonization method widely used in the mass production of tungsten carbide at home and abroad, the method introduced in this article can prepare high-quality tungsten carbide powder and is relatively simple to implement. It only needs to put a press in traditional tungsten carbide production lines.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com