The Zirconium Tungsten Electrode And Tungsten Electrodes Innovation

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 14:13

Tungsten electrodes are now an essential welding process of welding . The earliest tungsten electrodes are tungsten and tungsten -based synthetic metals thorium tungsten alloy . After a period of use , it was found downstream element thorium radioactive, radiation injury on the human body . So from what people have to study the new tungsten electrodes to replace the use of tungsten electrodes . Soon a number of tungsten electrodes was born.  < br />

< br />

In the 1980s , the emergence of yttrium tungsten electrode , because too many flaws of this electrode was gradually abandon the use of people .

Continued innovation in the 1990s , Beijing was born lanthanum tungsten electrode , the current from the performance indicators in terms of lanthanum tungsten electrode is the best alternative thorium tungsten electrode products , is now generally recognized.

In addition to the familiar cerium tungsten electrodes there is an intermediate product called zirconium tungsten electrode . Tungsten containing zirconia . Motor performance in the pure tungsten and thorium tungsten electrode. Tungsten in order to avoid the motor itself easily under high load conditions and the development of the melting conditions . Zirconium tungsten electrodes in AC current conditions showed good welding electrode tip can maintain spherical, and the arc is much more stable than pure tungsten electrodes . Zirconium tungsten electrodes biggest feature is that in the case of high load current welding, this electrode structure to reduce spherical tungsten seepage phenomenon and has good corrosion resistance. In general this zirconium tungsten electrodes for aluminum and its alloys will America AC welding .

The use of tungsten electrodes will determine the construction of the entire country , and even said that the earth of the welding industry. Five o'clock in the future will develop into what size , wait and see. Energy-saving , high efficiency which is getting good .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

About Ternary Complex Process of Tungsten Electrodes

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 14:10

People never stopped research on tungsten electrodes , thoriated tungsten electrodes from the basic to the present cerium tungsten electrode , lanthanum tungsten electrode , and the composite rare earth tungsten electrodes , gradual process and product quality innovation and progress forward . The composite rare earth tungsten electrode is the latest scientific research , our scientists are only carried out vigorously develop . One called ternary complex of tungsten electrode product was born.

Ternary rare earth tungsten electrode is a newly developed green electrode products, with excellent overall welding performance. This is the most promising substitute radioactive contamination of thorium tungsten motors, but because rare earth compound added three constituents , so the production process to bring a new problem , the tungsten electrode swaged and brushed finished products during processing rate decreased significantly. The researchers based swaging process temperature and pass deformation in different designs of the two processes. Plasticity of the electrode integrated use of the various stages of the process of optical metallographic microscopy , scanning electron microscopy and X- ray diffraction analysis and other methods of processing materials were obtained electrode microstructure analysis, we found the two in the formation process fibrous tissue with different characteristics . Good processing performance in which processing technology , fibrotic tissue fibers of uniform width , between the fibers arranged in neat rows . The researchers found that the type of processing parameters of the various stars fibrous tissue , and thus have different yield. Swaging process by adjusting the process parameters to improve the ternary complex of rare earth tungsten electrode production yield.

Ternary complex of rare earth production and application of tungsten electrodes , longevity good economic and social benefits.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Silver Characteristics And Performance of the Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 14:03

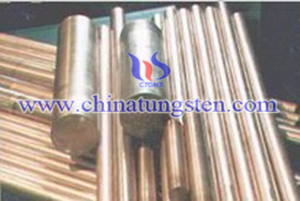

Binary alloy of silver and tungsten , whether in liquid or in solid, silver and tungsten are immiscible . There AgW30, AgW60, AgW80 and AgW90 so on. Hardness  high arc erosion resistance , anti- adhesion and anti- fusion welding ability. Manufactured by powder metallurgy . More than 60% tungsten alloy production of multi-use impregnated . Used for low-voltage power switch, crane switch, locomotive switch , high current switching pre- contact, as well as heavy-duty relays, air circuit breakers. Cobalt can be added to improve the wettability of silver tungsten , reduce the contact resistance .

high arc erosion resistance , anti- adhesion and anti- fusion welding ability. Manufactured by powder metallurgy . More than 60% tungsten alloy production of multi-use impregnated . Used for low-voltage power switch, crane switch, locomotive switch , high current switching pre- contact, as well as heavy-duty relays, air circuit breakers. Cobalt can be added to improve the wettability of silver tungsten , reduce the contact resistance .

Silver and tungsten sintered products , higher conductivity than copper tungsten , as mainly suitable for resistance welding electrodes require high antioxidant work environment . As EDM electrodes of the ordinary copper electrode when the finish is difficult to achieve , so that the abrasive to achieve a very high precision.

AGW-70 silver tungsten electrode materials, and mainly used in welding materials ; such as : low-voltage automatic switch, high voltage circuit breakers and protection switch and so on.

Need for silver tungsten electrodes , usually difficult to machine tool processing equipment and high- quality finish electrode, the electrode repair ordinary copper electrode to achieve the best finish , making the mold to achieve very high accuracy.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Silver Tungsten Electrodes for Various Models of Technical Parameters

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 13:59

Silver Tungsten Electrode Technical Parameters :

Product Name Symbol silver impurity conductivity IACS% tungsten Density g/cm3 Hardness HB ≥ bending strength

Silver Tungsten 30 AgW30 70 ± 1.5 0.5 margin 11.75 ; 75 75

Silver Tungsten 40 AgW40 60 ± 1.5 0.5 12.4 66 margin 85

Silver Tungsten 50 AgW50 50 ± 2.0 0.5 margin 13.15 57 105

Silver Tungsten 55 AgW55 45 ± 2.0 0.5 margin 13.55 54 115

Silver Tungsten 60 AgW60 40 ± 2.0 0.5 margin 14 51 125

Silver Tungsten 65 AgW65 35 ± 2.0 0.5 14.5 48 margin 135

Silver Tungsten 70 AgW70 30 ± 2.0 0.5 14.9 45 margin 150 657

Silver Tungsten 75 AgW75 25 ± 2.0 0.5 15.4 41 margin 165 686

Silver Tungsten 80 AgW80 20 ± 2.0 0.5 16.1 37 margin 180 72

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Silver Tungsten Alloy and Silver Tungsten Electrodes

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 13:56

The silver and tungsten and the alloy composition , a binary alloy of silver and tungsten . Because a high melting point of tungsten silver with each melt can not , so you can not use the traditional method of preparation , silver tungsten alloy powder metallurgy method of preparation must .

Silver tungsten alloy combines the advantages of silver and tungsten , high melting point, high specific gravity , cutting , high conductivity , wear resistance, damage , resistance welding , anti-oxidation ; is the electrode of the best, you can make a very general processing equipment and tool difficult to process out of the high finish of the electrode ; tungsten electrodes with silver electrodes better than ordinary to achieve the best finish results, so that the mold to achieve very high accuracy.

Silver tungsten is characterized by its high strength and resistance to soldering , mainly by the penetration and the nominal composition of the silver content from 20 to 50% . Tungsten increases, the hardness is reduced , and soldering ability . Whether liquid or solid, silver and tungsten can not be miscible. The material is characterized by high hardness , resistance to arc erosion , anti-adhesion , anti- welding capability.

Silver tungsten electrodes and electrode materials are mainly used in welding materials ; such as : voltage automatic switch, high voltage circuit breakers and protection switch and so on. Widely used in high temperature materials, high-voltage switch with electrical alloy , EDM electrodes , microelectronics materials, parts and components as widely used in aerospace , aviation , electronics, electric power, metallurgy , machinery, sports equipment and other industries.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

One Kind of A Method of Manufacturing AN Electrode of Tungsten Invention Yttrium

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 13:53

One kind of tungsten electrode yttrium invention discloses a manufacturing method for manufacturing the  tungsten electrode yttrium , the method comprising :

tungsten electrode yttrium , the method comprising :

a. Would doped yttrium nitrate aqueous solution spray evenly mixed with solid material way paratungstate (APT) or tungsten trioxide , heated drying coating made of tungsten, yttrium powder ;

b. Obtained for the yttrium -coated tungsten powder obtained after reduction twice yttrium tungsten powder , after pressing, sintering made of tungsten, yttrium billet ;

c. Forging pressure processing manner using the obtained tungsten billet made of yttrium Yttrium tungsten electrode . In this method, the yttrium nitrate aqueous solution was sprayed Doping mixed with ammonium paratungstate (APT) or tungsten oxide in the solid material in spray form the yttrium nitrate aqueous solution encapsulated in the ammonium paratungstate (APT) or tungsten trioxide of the surface to mixing, stirring, with the completion of drying , to prepare a uniform coated yttrium tungsten powder , improve the production capacity and make more uniform powder coating , yttrium tungsten effectively improved the performance in the welding electrodes .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

One Kinds of Method of Manufacturing The Tungsten Electrode Yttrium

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 13:48

One kind of tungsten electrode manufacturing yttrium, characterized in that:

a.The doped yttrium nitrate aqueous solution spray evenly mixed with solid material way paratungstate (APT) or tungsten trioxide, heated drying into powder-coated tungsten yttrium;

b.On the prepared powder coated tungsten yttrium twice yttrium tungsten powder obtained after reduction by pressing, sintering temperature yttrium billet made of tungsten;

c.Using the pressure processing method of the obtained forged tungsten billet made of yttrium Yttrium tungsten electrode.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How Will Fake Gold React to an Acid Test?

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 12:01

Gold is so soft that when jewelry is made from it, it is usually alloyed with one or a combination of copper, nickel, and silver. If gold jewelry is immersed in an individual acid, the gold itself will not dissolve, although the alloying metal does dissolve. If a chunk of metal is fake gold--if it consists of a metal sample in which there is very little to no gold--it will dissolve in nitric acid.

Density First

Before treatment with acid, the density of the jewelry should be evaluated. Gold has a density of 19.3 grams per cubic centimeter of metal. Copper and nickel are less dense than that--8.96 and 8.91 respectively. Silver has a density of 10.49. If the density of the jewelry is not appreciably more than 9, the piece is fake. Even if it has a trace of gold in it, perhaps a plated covering, it is less than the 10-Karat designation of the lowest grade of solid gold jewelry.

Pure Gold

Pure gold, called also 24-Karat gold, dissolves in alkali cyanide and in a few other unusual substances. It will not, however, dissolve in individual mineral acids. It does dissolve in certain combination acids, most notably "aqua regia" (a mixture of concentrated hydrochloric and nitric acids). Gold dissolved in aqua regia produces a dark amber-to-orange color.

Gold plated Tungsten Product Manufacturer & Supplier: Chinatungsten Online - http://paper-weight.cn/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

What Is Tungsten Gold?

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 11:56

Shoppers who are looking to buy real gold may unfortunately purchase tungsten gold, or fake gold, by accident. Fake tungsten gold bars are cheap substitutes for the real thing.

Background

Tungsten gold is considered the Ancient Metal of Kings. Tungsten is also called “the heavy stone.”

Pricing

While gold is priced in the tens of thousands per pound, tungsten costs less than $100 per pound. Charging the real gold price for tungsten gold leads to a huge profit.

Qualities

Tungsten gold is scratch-resistant and lightweight. Per cubic centimeter, it has a density of 19.25 grams at room temperature. At liquid density, it is 17.6 grams per cubic centimeter.

Determining Type of Gold

It’s difficult for the average person to quickly spot tungsten gold. However, those who are experienced in the gold industry can find ways to determine if the gold is fake or not.

Purity of Other Metals

Silver and platinum tend to be pure, since the materials are often melted down for making cell phones and catalytic converters.

Gold plated Tungsten Product Manufacturer & Supplier: Chinatungsten Online - http://paper-weight.cn/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Bucking Bar End-Effector For Upsetting a Rivet

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 11:03

A bucking bar assembly that positions a bucking bar for clamping a first panel and a second panel along a lap joint and upsets a rivet to fasten the first panel to the second panel at the lap joint. The assembly includes a lateral carriage system for moving the bucking bar along a length of the lap joint, and a rotational carriage system for rotating the bucking bar relative to the lateral carriage.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com