Tungsten-copper Composite Materials to Support the 5G Technology

- Details

- Category: Tungsten's News

- Published on Friday, 07 June 2024 10:57

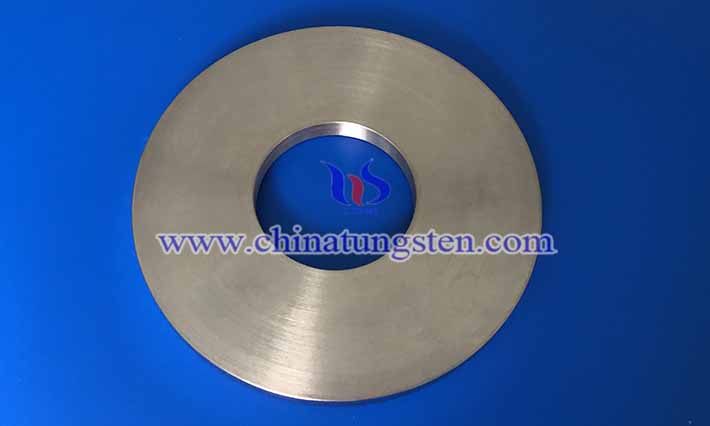

Tungsten-copper composite material is a kind of pseudo-alloy composed of tungsten and copper elements. It combines the high melting point, high density, and low coefficient of thermal expansion of tungsten with the high electrical conductivity and thermal conductivity of copper, providing strong support for the rapid and efficient transmission of 5G technology.

Electronic packaging materials are a kind of substrate material, whose main functions include carrying electronic components and their interconnections, providing mechanical support for these components, ensuring sealing environment protection, and effectively dissipating the heat generated by electronic components. Additionally, it must also have excellent electrical insulation performance as a sealant for integrated circuits. Tungsten-copper composite materials, with their unique physical and chemical properties, are widely used in electronic packaging materials.

In electronic packaging materials, the application of this composite materials mainly manifests in the following aspects: Firstly, the high melting point and high density of tungsten ensure that the material can maintain stable performance even in high-temperature environments. Secondly, the high electrical conductivity and thermal conductivity of copper ensure fast signal transmission and efficient heat dissipation of the equipment. Thirdly, the low coefficient of thermal expansion of the composite materials enables them to have minimal dimensional changes when the temperature changes, which is crucial for maintaining the stability and reliability of the packaging structure.

Tungsten-copper composite materials can be produced using the infiltration method: Tungsten powder is pressed into green compacts with a certain shape and strength, then sintered at high temperatures to remove binders and other impurities from the green compacts, while forming a certain bond between tungsten particles, forming a tungsten skeleton with a certain porosity. Next, molten copper metal is injected into it. Under the capillary action, the copper melt flows through the interstices between the tungsten particles, filling and wetting the pores of the tungsten skeleton. Finally, after appropriate cooling, the copper and tungsten skeleton are tightly combined to form dense tungsten-copper alloy.

Chinatungsten Online is a professional manufacturer of tungsten and molybdenum for nearly thirty years. We can supply tungsten copper heat sink materials as per the drawings. Please free feel to contact us when you got the purchasing plans.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com