Re Addition Improves Charpy Impact of Modified Tungsten Materials

- Details

- Category: Tungsten's News

- Published on Monday, 29 May 2023 19:25

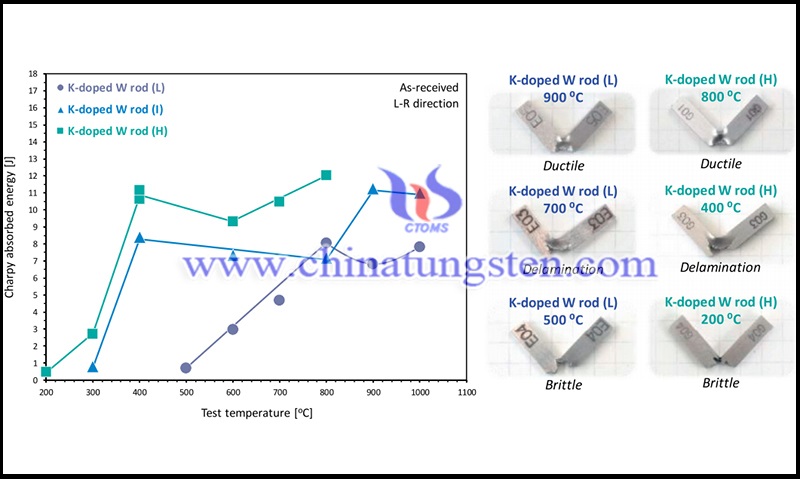

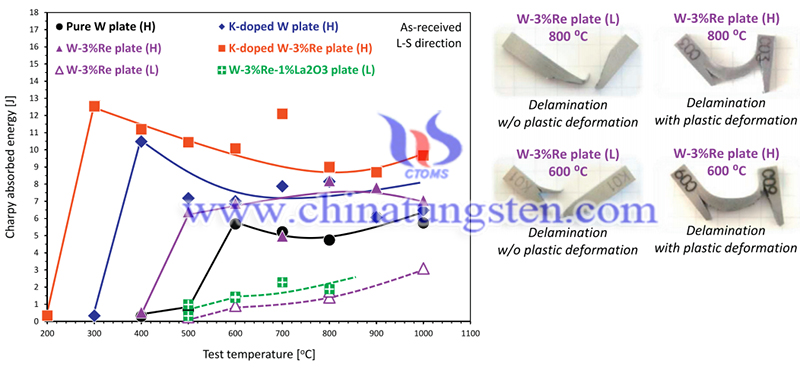

It was shown that the dispersion of K-bubbles could not directly affect the Charpy impact performance of the modified tungsten materials below 1000 °C, although the improvement of the impact performance by grain refinement induced by K-doping was significant. In the case of W-3% Re(H) and K-doped W-3% Re(H) plates, the effect of Re addition broadly consists of grain refinement effects caused by the inhibition of grain boundary movement by solute Re, and solid solution strengthening and softening effects caused by solute Re.

Therefore, the improvement of Charpy impact properties of W due to Re addition can be attributed to grain refinement and solid solution strengthening and softening. Thus, below 1000°C, it is possible that DBTT and USE are roughly determined by the effects of grain size and Re-addition. In contrast, W-3%Re(L) and W-3%Re-1%La2O3(L) plates do not obey these relations. This may be due to insufficient deformation rate in rolling to obtain the desired grain matrix (number density and size of sub-grains and dislocations, etc.) and grain boundaries (strength and characteristics, etc.).

As for the highly deformed rolled plates below DBTT, pure W(H) plates showed crack fracture, while K-doped W(H), W-3% Re(H) and K-doped W-3% Re(H) plates showed intergranular fracture at subgrain boundaries, in contrast, intergranular fracture at subgrain boundaries was observed in all four materials above DBTT. According to Curry and Knott, fracture fracture stress can increase with grain refinement. Therefore, one of the reasons for the inhibition of fracture fracture in K-doped W, W-3% Re and K-doped W-3% Re compared to pure W could be grain refinement.

According to the results of Charpy impact tests for these materials received along the L-S direction, DBTT and USE were improved by K-doping and Re-addition if the deformation rate in rolling was sufficiently high. On the contrary, no significant positive effect of La2O3 particle dispersion was observed for materials with low deformation. However, there is anisotropy in the grain structure in rolled sheets and forged bars, which may also lead to anisotropy in Charpy impact properties.

For example, Rieth et al. and Reiser et al. reported anisotropy in Charpy impact properties of rolled plates and round blanks of pure W and W alloys. In their experiments, some materials showed significantly lower absorbed energy in directions other than along the L-S direction. Therefore, further evaluation of the Charpy impact property anisotropy is planned as future work to fully understand the effect of modification by K-doping, La2O3 particle dispersion and Re-addition.

Reference: Nogami S, Hasegawa A, Fukuda M, et al. Mechanical properties of tungsten: recent research on modified tungsten materials in Japan[J]. Journal of Nuclear Materials, 2021, 543: 152506.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com