Effect of Chromium and Molybdenum Content on Cobalt Alloys

- Details

- Category: Tungsten's News

- Published on Sunday, 02 October 2022 19:17

Cobalt(Co)-chromium(Cr)-molybdenum(Mo) alloy systems are widely used in orthopedic implants because of their excellent metallic properties. A recent study was conducted by researchers on the effect of increments of chromium (Cr) and molybdenum (Mo) on the crystal structure, nanoindentation and corrosion properties of cobalt alloys. The study focused on the structural, physicochemical and nanoindentation properties of the Co-Cr-Mo alloy system.

Many research groups are currently working to create new alloys and metals to improve the effectiveness of orthopedic implants, especially for younger and more active patients. Co-Cr-Mo systems are an important alloy group in this regard because of their exceptional physical reliability, wear effectiveness and corrosion resistance.

While ASTM guidelines limit the alloy configurations of Co-Cr-Mo alloy systems, they also provide compositional regions within which a variety of alloy configurations with different nanostructures and phase compositions can be obtained. This allows the mechanical, nanoindentation and electrical properties of Co-Cr-Mo alloy systems to be customized.

The physical and rheological characteristics of the Co-Cr-Mo alloy system derive from the crystal structure and metallurgical morphology of the alloy, both of which are determined by the alloy composition.

Carbon is a key component in the Co-Cr-Mo alloy system. Although carbon is insoluble in pure cobalt, it produces carbides with Cr and Mo, which act as crystals within the matrix and prevent dislocation slip.

These carbides can help strengthen Co-Cr-Mo alloys, although their effect on the rheological effect varies depending on how the alloy is treated. The treatment procedure has an effect on the shape, content, dispersion and size distribution of the carbides within the matrix, which in turn affects the efficiency of the Co-Cr-Mo alloy system.

Cobalt, chromium and molybdenum can coexist as a single stable mixture in either the face-centered cubic (FCC) or hexagonal dense (HCP) phases. Pure cobalt undergoes a transition from the FCC to the HCP phase at 417 degrees Celsius. However, when it is combined with HCP Cr and Mo alloys, the transition temperature rises.

The FCC state in these materials has greater flexibility and elastic modulus, but the low lattice distortion energy of the alloy limits dislocation cross-slip. This causes extensive stacking defects in the Co-Cr-Mo alloys, allowing strain-induced changes to become HCP phases.

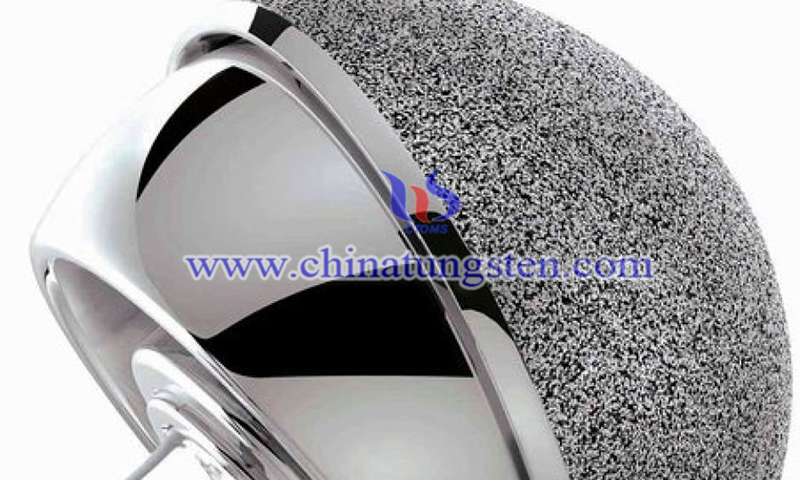

(Picture source: icdeurope.com)

These modifications have improved the tribological properties of the alloy. Not only does it make the Co-Cr-Mo alloy surface tougher, but the coefficient of friction produced by the single crystal HCP alloy is approximately 50% lower than that obtained from the FCC alloy under the same conditions and sliding speeds.

Pure cobalt is volatile and susceptible to corrosive attack when used in chlorine-rich environments. Chromium prevents this volatility by forming a reinforced passive oxide film at the alloy interface. The passive effect is further supported by the addition of molybdenum in the form of an oxide or metal.

Although Cr, Co, and Mo are required for specific metabolic functions in the body, any increase above a certain level is considered undesirable due to the possible inflammatory response.

Since the content of the Co-Cr-Mo system is key in determining its properties, researchers have focused on producing diverse alloy compositions. X-ray diffraction was used to study the effect on the crystalline structure. In addition, an attempt was made to determine the optimum Co-Cr-Mo alloy content with better corrosion and mechanical properties.

The toughness of Co-Cr-Mo alloys increases linearly with the percentage of chromium. Open circuit voltage, linear sweep potentiometry and polarization resistance measurements show that adding Cr to 30 wt.% increases the passivation of the Co-Cr-Mo system and any subsequent increase produces a deterioration in corrosion characteristics.

Based on these findings, the researchers concluded that the Co-Cr-Mo alloy investigated in this study has good potential for many orthopedic applications, requiring only careful adjustment of the concentration of the cobalt alloys content.

(Article source: www.azonano.com)

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com