Defense Metals Yields Improved Rare Earth Recovery at Wicheeda Project

- Details

- Category: Tungsten's News

- Published on Monday, 06 June 2022 23:35

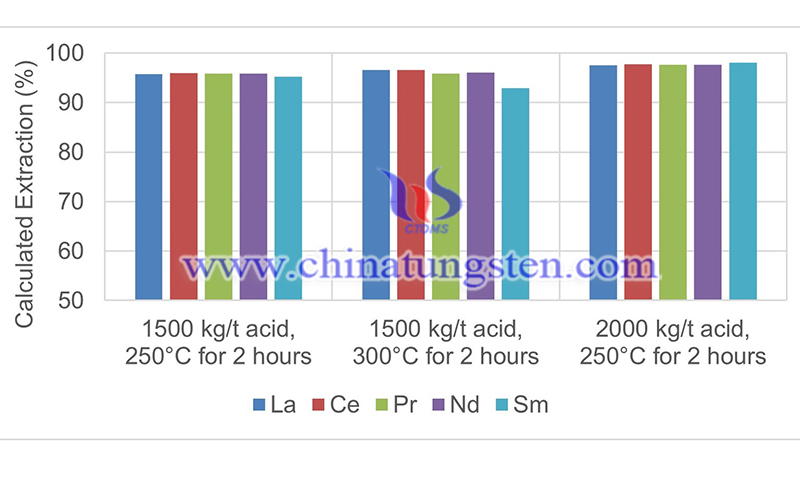

Defense Metals Corp. announced preliminary results of alternative Acid Bake process test work on mineralized feedstock at the Wicheeda project, which showed that the use of the Acid Bake process could improve the efficiency of rare earth recovery and potentially improve capital and operating costs.

The hydrometallurgical flow chart previously included in the PEA (Preliminary Economic Assessment) was based on the more costly and complex gangue-leach-caustic-crack process. Subsequently, John Goode, P.Eng., Chief Metallurgical Consultant for Defense Metals, recommended an investigation of the acid roasting process for the Wicheeda ore, and preliminary results showed that the Acid Bake process is more efficient, with over 95% extraction of neodymium and praseodymium from the flotation concentrate to the leach solution.

This hydrometallurgical program, which began in December and includes the operation of a pilot plant, will conclude in the last quarter of 2022. It will provide data for detailed design as well as capital and operating cost calculations. Once the results are available, the company will provide regular updates on the test work.

Luisa Moreno, President of Defense Metals, commented, "We are pleased that the acid-bake process has yielded higher rare earth extraction rates and offers the potential to significantly reduce operating and capital costs, thereby improving the economics of the project and further establishing the Wicheeda project as a potential near-term source of rare earths."

In the AB-WL process, Wicheeda's mineral concentrate will be treated with concentrated sulfuric acid at high temperatures (200˚C-600˚C) to convert the rare earths in the mineral to water-soluble sulfates that dissolve readily in the subsequent water leaching process. The leachate is then purified and the rare earth elements are extracted by a simple precipitation process.

The process requires less equipment and involves fewer steps and circuits. The flow chart for defense metals is the same as that used at Lynas' rare earth production plant in Kuantan and the rare earth recovery plant in Bayan Obo (using basalt and monazite ores), and most of the world's REEs are currently produced by the Acid-Bake process.

The Company's 100% owned 2,008-hectare Wicheeda Rare Earth Project, located approximately 80 kilometers northeast of Prince George, British Columbia, is accessible via an all-weather gravel road and is in close proximity to infrastructure such as power transmission lines, railroads, and major highways. a unique advantage of the Wicheeda Rare Earth Project is its ability to produce a marketable, high-grade flotation concentrate.

Defense Metals Corporation is a mineral exploration and development company focused on acquiring, exploring, and developing deposits containing metals and elements commonly used in the power market, defense industry, national security sector, and green energy technology production, such as rare earth magnets for wind turbines and permanent magnet motors for electric vehicles.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com