MoO2 Quantum Dots Enhance Copper Composites

- Details

- Category: Tungsten's News

- Published on Sunday, 05 June 2022 22:31

A recent study develops a hydrothermal technique for generating linked-bridge MoO2 quantum dots to improve the physical and mechanical properties of copper composites.

Due to its superior electrical properties, thermal conductivity, and chemical inertness, copper and its composites have been widely used as structural components in engineering applications. Copper matrix composites (CMCs) are the most attractive materials for technical applications that require excellent temperature tolerance and microstructural durability.

Nowadays, copper matrix composites need to have stronger overall performance in order to meet the needs of many fields, including aerospace, electrified railway lines, automotive, and electronics. Therefore, different reinforcement materials are essential for the long-term development of copper-metal matrix composites.

(Source: W. Tong/Materials Science & Engineering)

The incorporation of nanoparticles as reinforcement in CMC is a viable technique to improve its mechanical properties to meet these growing demands. Nanoparticles of metal oxides, carbides and nitrides are often used to reinforce copper structures.

Molybdenum (Mo) is of great interest to the scientific community due to its high modulus of elasticity, toughness, and low cost. Due to the synergistic effect in the nanocomposite framework, the introduction of molybdenum dioxide (MoO2) can significantly increase the friction reduction and the degradation behavior of the copper matrix.

Nanomaterial-reinforced CMCs require strong interfacial adhesion and uniform reinforcement dispersion in the composite for good overall properties. However, the aggregation of nanoparticles with increasing reinforcement concentration has become a major obstacle to the practical application of these composites.

The aggregation of enhanced nanoparticles in the copper matrix causes stress accumulation, leading to the formation of early microcracks and degradation of mechanical properties.

To increase the homogeneous dispersion of nano-reinforced materials, several techniques can be used, such as physical alloying, in situ production, hydrothermal processes, chemical coating, molecular-level mixing, and spray pyrolysis. Hydrothermal methods are the most widely used because the concentration of nanomaterials to be produced can be well regulated by liquid-phase or multiphase chemical processes.

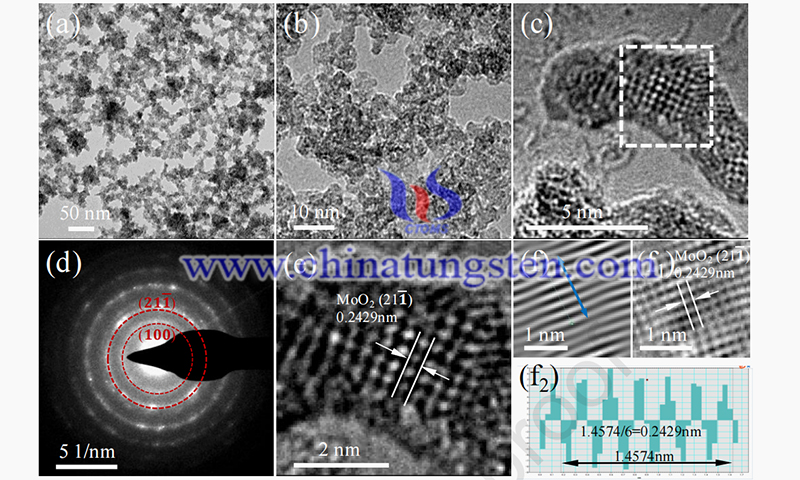

In this study, the researchers used a simple hydrothermal method to create unique bridge-like and connected molybdenum dioxide quantum dots (MoO2 QDs). Due to the brittle nature of the interconnected structure, the resulting MoO2 quantum dots may be easily broken and uniformly dispersed into the copper substrate during the alloying process.

A hydrogen reduction procedure was used to produce copper composites. Finally, the reinforcement of the composites was thoroughly examined and treated using different characterization methods.

The X-ray diffraction (XRD) technique was used to examine the phases of copper composites. The phase structure of MoO2 QDs was examined using X-ray photoelectron spectroscopy (XPS), with an aluminum target as the excitation source. The structural properties and tensile fracture morphology of the composites were examined using field emission scanning electron microscopy (FE-SEM).

In this study, the researchers created unique MoO2 quantum dots by using a hydrothermal method to strengthen copper matrix composites (CMCs). Due to the interconnected structure and brittleness of the quantum dots, the quantum dots are easily broken and dispersed into the copper matrix in the ball milling method.

(Source: Intothelight Photography/Shutterstock.com)

The mechanical properties of the composite can be tuned by changing the amount of MoO2 Based on the proper distribution of MoO2 QDs, the cohesive interaction between MoO2 and copper and the mechanical properties of the composites can be synergistically enhanced. Reinforcement of copper composites with MoO2 QDs allowed for an increase in yield force and ultimate tensile strength while maintaining good electrical conductivity and elongation.

The study titled “Improving mechanical properties of copper composite by interconnected MoO2 quantum dots” has been published in Materials Science & Engineering, A (2022). The study was carried out by W. Tong, Y. An, C. Bao, D. Fang, M. Wang, J. Yi.

This research lays the groundwork for the creation of copper-based composites that can vary the shape of the reinforcing particles to improve their dispersibility. This discovery is expected to open the way for expanding the use of nanoparticle-reinforced composites in the near future.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com