Space-Confined Method to Synthesize MoS2-Wrapped SWNTs

- Details

- Category: Tungsten's News

- Published on Wednesday, 13 April 2022 13:01

A group of researchers recently published a paper in Carbon demonstrating the use of a space-confined method to synthesize MoS2-wrapped SWNTs (single-walled carbon nanotubes) that can be effectively used to develop novel one-dimensional (1D) van der Waals (vdW) heterojunctions.

One-dimensional nanostructures, such as CNTs and semiconductor nanowires, are considered suitable for the fabrication and design of different functional vdW and core-shell heterojunctions with great potential for various applications in catalysts, conductors, batteries, and nanoelectronics.

In one-dimensional nanostructures, CNTs can be assembled into macroscopic configurations, such as sponges and thin films, and then merged with other materials to prepare coaxial structures. For example, polymers or metals are wrapped around or deposited on CNT fibers to improve the electrical conductivity and strength of the fibers and to fabricate functional devices such as wearable and high-sensitivity strain sensors.

Following a similar approach, porous CNT sponges can be coated with various transition metal disulfides, such as tin sulfide (SnS2) and molybdenum disulfide (MoS2), by in situ hydrothermal methods to synthesize a series of coaxial heterostructures that can be used for lithium-ion battery electrodes and strain sensors.

SWCNTs represent an ideal template for the construction of one-dimensional heterojunctions because of their diameter of less than 2 nm and their exceptional electrical and mechanical properties such as tunable conductivity behavior, excellent flexibility, ultra-high-modulus, and strength. However, homogeneous wrapping of two-dimensional (2D) nanosheets or crystalline layers on SWCNTs is still very challenging due to their large curvature and small diameter.

Currently, due to these challenges, other materials are usually attached to SWCNTs rather than forming a coaxial structure. However, some MoS2-wrapped SWNTs 1D vdW heterojunctions have recently been successfully fabricated. For example, coaxial nanotubes of SWCNT@boron nitride nanotube (BNNT)@MoS2 were prepared by directly growing BNNT and MoS2 sequentially using a chemical vapor deposition (CVD) method. However, the yields of SWCNT@BNNT@MoS2 obtained by this method are very low. Therefore, scalable and reliable synthesis methods must be developed to fabricate one-dimensional heterostructures with greater versatility and in large quantities.

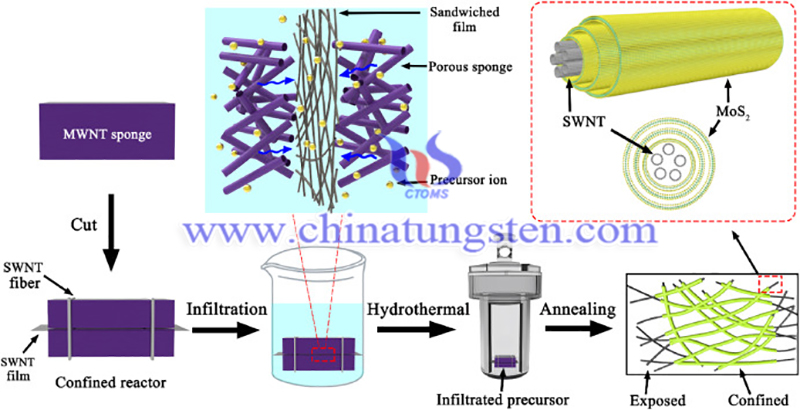

In this study, the researchers synthesized SWCNT@MoS2 films by hydrothermally wrapping MoS2 crystalline layers around SWCNT bundles, which were synthesized by the space-confined method.

Hydrothermal deposition represents a scalable and simple method to synthesize large amounts of highly crystalline MoS2-coated SWCNT bundles. Tunable MoS2 sheets can be used to coat SWCNT bundles. Ethanol, hydrochloric acid, ammonium molybdate, sulfuric acid, thiourea, ferrocene, 1,2-dichlorobenzene, sublimated sulfur, and xylene were used as starting materials.

Initially, the floating catalyst CVD method was used to synthesize SWCNT membranes at 1200 degrees Celsius. Sulfur/ferrocene was used as a catalyst and xylene was utilized as a precursor in the SWCNT synthesis. The atmospheric pressure CVD method was used to synthesize multi-walled CNT (MWCNT) sponges at 860 degrees Celsius. Ferrocene and 1, 2-dichlorobenzene were used as catalysts and carbon precursors, respectively.

Two MWCNT porous blocks were fabricated by cutting the MWCNT sponges and then binding them with SWCNT fibers to prevent dispersion. Subsequently, the SWCNT films were sandwiched between the MWCNT porous blocks, and the sandwiched SWCNT films were immersed in a 100 mg/ml ammonium molybdate solution for 30 min. The sandwiched films were freeze-dried and again immersed in a molten thiourea bath at 200 °C for 30 min.

Finally, the samples were placed in a Teflon wire autoclave for 12 hours at 120 degrees Celsius to obtain the encapsulated amorphous MoS2 layer. The final intercalated samples were annealed at 800 degrees C for 4 hours under the protection of an argon gas stream in order to improve the crystallinity of MoS2 before collecting the SWCNT@MoS2 films. The MoS2 loading in the SWCNT@MoS2 films was controlled by varying the concentration of the molybdenum precursor.

SWCNT bundles and flexible, ultrathin, large-area SWCNT@MoS2 films were successfully synthesized by the space-confined method supported by porous MWCNT sponges and the hydrothermal method, respectively. The crystallized multi-walled MoS2 sheets were formed continuously and uniformly around the SWCNT bundles. Tunable MoS2 layers surround the SWCNT bundles with sizes ranging from a few nanometers to several hundred nanometers.

The SWCNT@MoS2 samples show significantly enhanced gas sensitivity and optical response compared to the original SWCNT films due to the combination of electrical and optical properties of MoS2 and SWCNT in the films, making them suitable and effective as flexible photodetectors and toxic gas sensors. The formation of a one-dimensional heterojunction and the homogeneous MoS2 coating together lead to changes in the current due to gas absorption or light illumination.

The results of this study show that the space-confined method used to synthesize MoS2-wrapped SWNTs thin films also utilizes more transition metal dichloride and other materials to efficiently synthesize different one-dimensional heterojunction nanotube structures and assemble flexible large-area optoelectronic and electronic devices.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com