Effect of Coating Tungsten Wires with Reactive Multilayer Films

- Details

- Category: Tungsten's News

- Published on Thursday, 27 January 2022 21:30

In a study published in Materials, researchers discuss the use of reactive multilayer films to coat tungsten wires to induce an exothermic reaction. The heat generated by this reaction is used to liquefy materials with low melting points and to stop the expansion of cracks in metallic materials.

Under certain conditions, exothermic reactions occur between metals, which can lead to spontaneous high-temperature synthesis (SHS). Reactive multilayer films are usually deposited by physical vapor deposition techniques such as sputtering or DC magnetron sputtering.

Due to the exothermic and self-propagating properties of reactive multilayers, they are often used as local heat sources and the multilayers can be used for self-healing applications where the released heat promotes the melting of the repair material.

In this study, the researchers used direct current (DC) magnetron sputtering to deposit Ni/Me (Me = Al, Ti) multilayers from two targets - nickel and Me - onto tungsten wires with diameters of 0.05 and 0.20 mm. To minimize cross-contamination and prevent the mixing of atomic fluxes, the researchers placed a stainless-steel shield between the two targets.

The researchers used energy dispersive spectroscopy (EDS) to evaluate the average chemical composition in the multilayer films. After obtaining the desired chemical composition, Ni/Me multilayer films were deposited onto different diameters of tungsten wires.

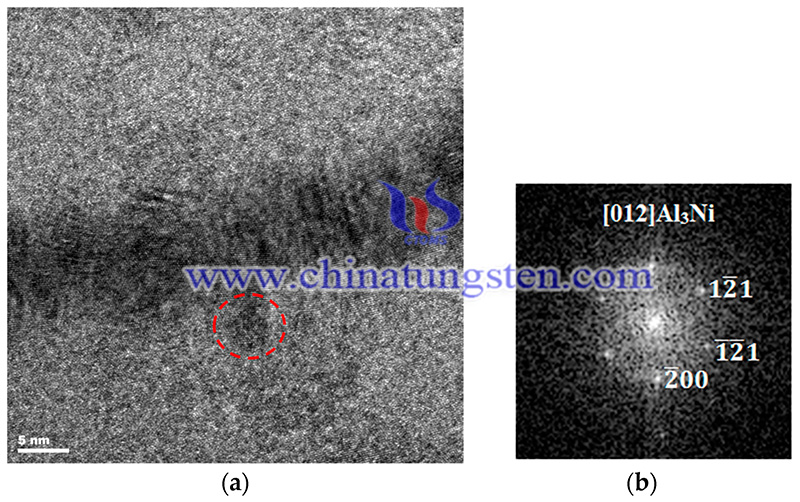

The presence of the Al3Ni intermetallic phase is interpreted as a local reaction between Ni and excess Al during deposition without substrate cooling. Differential scanning calorimetry (DSC) measurements indicate that the reaction occurs below 200°C, at intermediate times between ~25 and ~40 nm.

Based on the chemical composition results, there is a slight nickel enrichment and the electron diffraction pattern is mainly indexed as B2-AlNi, although some low-intensity peaks are present, indicating a nickel-rich minor phase like AlNi3.

Deposition of nanoscale reactive multilayer thin films onto small diameter wires is a challenging task. This study shows that coating tungsten wires with reactive multilayer films help crack filling and turns W wires into actuators capable of self-repair.

While TEM confirmed the nano structural characteristics of the Ni/Me multilayer films deposited on the tungsten wire, a new substrate holder resolved the defects, resulting in a more uniform film across the tungsten wire. In the Ni-Ti system, multilayer films without any defects were deposited independently of wire diameter, substrate support, or modulation period.

In conclusion, the self-propagation and heat release illustrated in this method of producing multilayer-coated tungsten wires is very promising in the development of actuators that can be used for self-healing applications.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com