3D Printing Technology Supports Tungsten Manufacturing

- Details

- Category: Tungsten's News

- Published on Friday, 07 May 2021 14:29

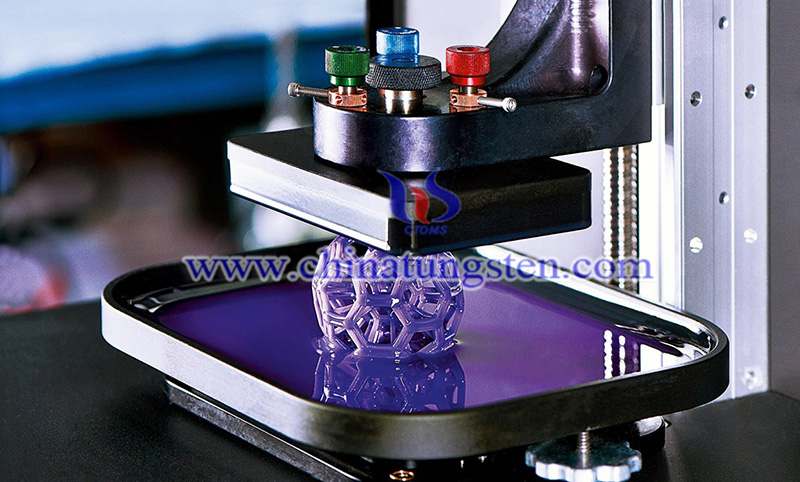

3D printing technology supports tungsten manufacturing. 3D printing is a rapid prototyping technology based on digital model files, using powdered metal or plastic and other bondable materials to construct objects by printing layer by layer. In simple terms, it is similar to the upgraded version of the plus version of paper printing, except that the ink is replaced with metal powder, ceramics, plastics, sand and other materials. The printed product can be a more three-dimensional object with a more complex structure.

Tungsten is a kind of metal material, but it is the metal with the highest melting point, which can reach 3410±20℃. This is one of the vital advantages that tungsten and its products can be widely used, but in 3D printing, it has also become a major technical difficulty that needs to be overcome.

But as the saying goes, life itself is a process of constantly encountering and solving problems, and there are always more solutions than problems. Once the pain points that are difficult to process tungsten can be overcome, 3D printing can also open up broader application prospects for tungsten metal.

For example, 3D printed tungsten anti-scatter grids have been used more recently. Such products are generally used in medical CT detectors to absorb and filter scattered and refracted X-rays. Therefore, there are higher requirements for the hardness, precision, and radiation absorption ability of the material.

The use of 3D printing technology can more efficiently print anti-scatter grids with thinner wall thickness, higher density, stronger stiffness, more scattered radiation absorption, better shading, greater design flexibility and freedom, but during production, it is necessary to overcome the technical difficulties that the low temperature brittleness of tungsten alloys can easily cause cracking. It is reported that the metal 3D printing limit thin wall that has been tackled at present is 0.1mm, which is made in China.

Another example is 3D printing engines, rocket nozzles and other high-temperature tungsten alloy products. Tungsten is widely applied in extreme fields such as aerospace, national defense, military industry, and even nuclear weapons due to its high temperature resistance, corrosion resistance, creep resistance, thermal conductivity, electrical conductivity, environmental protection, and non-toxic properties.

As the teeth of modern industry, the development of 3D printing tungsten materials has important practical significance. It's reported that Chinese companies have successfully implemented the world's first full-size 3D printed aircraft engine. 3D printing technology supports the tungsten manufacturing industry.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com