Japan Invents New Battery 90% Cheaper Than Li-Ion Battery

- Details

- Category: Tungsten's News

- Published on Monday, 13 July 2020 19:15

Li-ion battery plays a central role in the scientific and technological world, powering various devices such as smartphones and smart cars, and now a people in Japan who helped commercialize them says he has a way to cut mass production costs by 90 percent and significantly improve their safety. Hideaki Horie, who was responsible for battery research at Nissan Motor Co., established APB, a Tokyo-based company, in 2018 to make "all-polymer batteries."

Before this, Nissan had licensed an advanced technology to APB to produce this battery. Nissan began to develop Li-ion batteries in the early 1990s, launched the Prairie Joy EV in 1997, and became a pioneer in installing lithium-ion batteries in commercial electric vehicles. Earlier this year, APB received backing from a group of firms including general contractor Obayashi Corp., industrial equipment manufacturer Yokogawa Electric Corp. and carbon fiber producer Teijin Ltd.

In March of this year, APB raised 8 billion yen ($74 million). which is tiny by the wider industry's standards but will be enough to fully equip one factory for mass production slated to start next year. Horie estimates that its plant in central Japan will have an installed capacity of 1 gigawatt-hour capacity by 2023. "The problem with making lithium batteries now is that it's device manufacturing, like semiconductors," Horie said in an interview. "Our goal is to make it more like steel production."

The basic unit of the battery-the manufacture of Li-ion battery cells is a complex process that needs to be completed under clean room conditions-requires humidity control and continuous air filtration to prevent contamination of highly reactive materials. The setup can be so expensive that just a handful of top players, like South Korea's LG Chem Ltd., China's CATL and Japan's Panasonic Corp., can spend billions of dollars building a suitable factory.

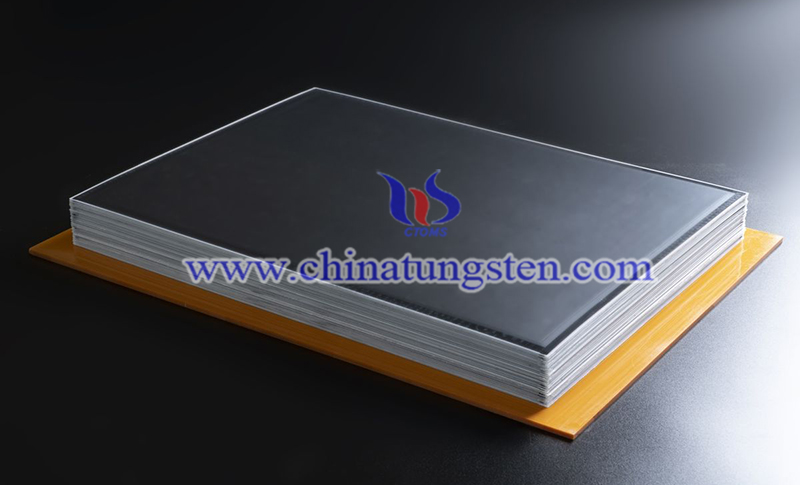

Horie's innovation is to replace the basic components, which are metal-lined electrodes and liquid electrolytes, with a resin construction. He said that this method greatly simplifies and speeds up the production process, as easy as "buttering toast." The modification allows for 10-meter-long battery sheets to be stacked on top of each other "like seat cushions" to increase capacity, he said. Importantly, the resin-based batteries are also resistant to catching fire when punctured.

Lithium-ion batteries have come a long way since they were first commercialized nearly thirty years ago. They last longer, pack more power, and cost 85 percent less than they did 10 years ago, serving as the quiet workhorse driving the growth of smartphones and tablets with ever more powerful internals. But safety remains an issue and batteries have been the cause of fires in everything from Tesla Inc.'s cars to Boeing Co.'s Dreamliner jets and Samsung Electronics Co.'s smartphones.

Hideaki Horie said: "Just from the standpoint of physics, the lithium-ion battery is the best heater humanity has ever created."

However, the resin battery has fire resistance when punctured. In traditional batteries, a puncture will generate hundreds of thousands of amps of a surge, which is several times the current of ordinary households. The temperature will rise to 700 degrees Celsius. The APB battery uses a so-called bipolar design, which eliminates the current power bottleneck and allows the entire surface of the battery to absorb surges, thereby avoiding this catastrophic situation.

"Due to many accidents, safety has always been the top priority in the industry," said Mitalee Gupta, a senior analyst at the Wood Mackenzie energy storage team. "If the company can scale up quickly, this is a breakthrough for storage and electric vehicle applications."

But this technology is not without shortcomings. Menahem Anderman, president of California-based consulting company Total Battery Consulting Inc., believes that polymers are less conductive than metals, which may seriously affect the battery's carrying capacity.

He said that capital is not killing the cost of a Li-ion battery, lithium-ion with liquid electrolyte will remain the main application for another 15 years or more. It’s not perfect and it isn’t cheap, but beyond lithium-ion is a better lithium-ion. Hideaki Horie from Japan admitted that APB cannot compete with battery giants that have invested billions of dollars and benefited from economies of scale. APB will focus on fixed batteries used in buildings, offices, and power plants.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com