Progress in R&D of Rare Earth Toughening Modifier for Polylactic Acid

- Details

- Category: Tungsten's News

- Published on Wednesday, 04 March 2020 19:19

In the research and development of polylactic acid (PLA) rare earth toughening modifier, Baotou Research Institute of Rare Earth in Inner Mongolia has achieved breakthroughs. Test results of the PLA modifier could meet the technical requirements of downstream customers.

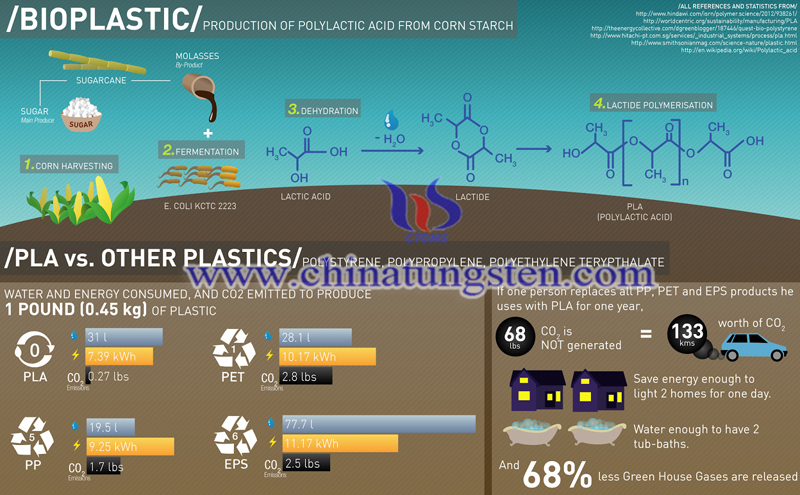

Polylactic acid is a biodegradable polymer resin, which not only has environmentally-friendly characteristics during use and after being discarded but also its raw material, lactic acid, is obtained after fermentation of starch extracted from plants such as corn, wheat, cassava. In 2010, PLA had the second highest consumption volume of any bioplastic of the world, although it is still not a commodity polymer. Its widespread application has been hindered by numerous physical and processing shortcomings. PLA is the most widely used plastic filament material in 3D printing.

However, shortcomings such as brittleness, low elongation at break, poor toughness, poor thermal stability, and high cost have hindered the further promotion of PLA. "Improve the performance of polylactic acid and increase its market application value. This is the starting point for us to launch the research of PLA additives." Hongzhang Cao, director of the rare earth additives project team of the pilot base of Baotou Research Institute of Rare Earth, introduced that the research is mainly by adding two rare earth additives that are used to improve the toughness of PLA. Presently, it has passed use evaluation and has carried out continuous industrial tests, which can fully meet the user's requirements.

It is reported that polylactic acid, as a thermoplastic aliphatic polyester, contains a large number of carbon-oxygen bonds, carbonyl groups, and terminal hydroxyl groups, which easily absorb moisture and undergo autocatalytic thermal decomposition of the terminal groups. Rare-earth ions could form bidentate chelation, bidentate bridging, and monodentate with carboxyl oxygen ions, making the rare earth complexes form layered, infinite chain and network polymers in polymer organisms.

For future market applications, Hongzhang Cao is confident. "Our products are not only environmentally-friendly, but also low in price compared with imported products. Take the BASF modifier currently used as an example, the cost is about 250,000 yuan per ton, and our cost is 100,000 yuan per ton. The most important thing is that rare earth resources are China's advantageous resources. Rare earth modifiers are self-synthetic products, and auxiliary materials can be provided by domestic manufacturers without importing." Hongzhang Cao said.

According to reports, the high-performance polylactic acid rare earth toughening modifier developed by Baotou Research Institute of Rare Earth recently passed the inspection and identification of SGS. The rare earth toughening modifier is non-toxic, odorless, environmentally friendly, and the price is far lower than imported additives, bringing a promising future to the domestic market.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com