New Cathode From Molybdenum and Sulfur Could Enhance the Future Lithium Ion Batteries

- Details

- Category: Tungsten's News

- Published on Friday, 19 July 2019 09:47

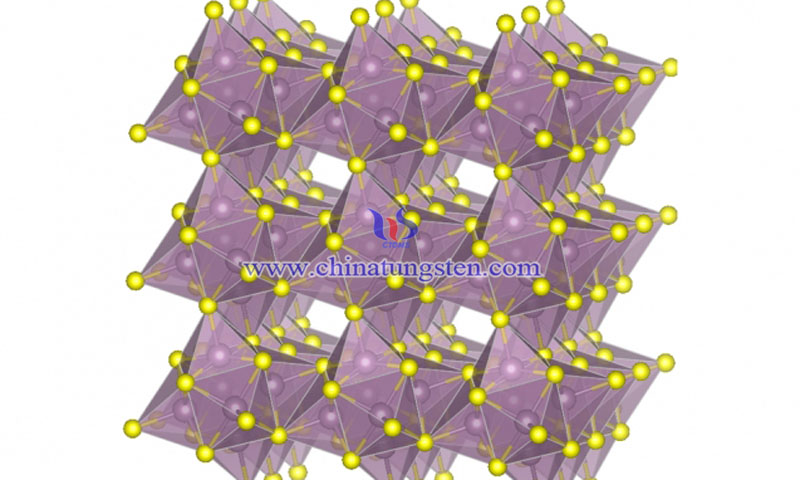

MIT's recent press release describes MIT and Chinese researchers’ efforts to develop a new version of the molybdenum-sulfur cathode. All three components of lithium-ion batteries have been thoroughly studied to find ways to increase not only the energy output per pound (weight energy density), but also the energy density per liter (volume energy density). These two goals are often difficult to achieve at the same time. Nevertheless, in the announcement, the team described their concept as a "hybrid" cathode. This is because it combines the aspects of two different methods to increase the energy density of weight and volume. The new cathode incorporates both a type of molybdenum sulfide called Chevrel-phase, and pure sulfur, and the results suggest in both gravimetric and volumetric energy densities can be achieved.

The new hybrid cathode provides encouraging results. According to news reports, "today's commercial lithium-ion batteries have energy densities of about 250 Watt hours per kilogram and 700 watt hours per liter, while lithium-sulfur batteries can reach up to 400 watt hours per kilogram, but are limited to 400 watt hours per liter. The researcher Li said that the initial version of the new version has not yet through the optimization process and has reached more than 360 watt-hours per kilogram and 581 watt-hours per liter. In terms of the combination of these energy densities, it can defeat lithium-ion batteries and lithium-sulfur batteries.

With further work, Li said, "We think we can reach 400 watt-hours per kilogram and 700 watt-hours per liter." The latter figure is comparable to that of lithium ions. One reason the results look promising is the way they are studied. Instead of testing small button batteries with a capacity of just a few milliamp-hours, the team produced three-layer bag batteries with a capacity of more than 1,000 milliamp-hours. By building test batteries comparable to some commercial batteries, such as those used in electric vehicles, they can better evaluate the performance of new hybrid cathodes. Further work will include improving the number of charge-discharge cycles that batteries can experience before losing too much power. "It's not a cathode problem," Li said; it's related to the overall battery design, and we're working on it.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com