Tungsten Carbide Drill Bits Sharpening

- Details

- Category: Tungsten Information

- Published on Thursday, 23 October 2014 18:06

- Written by xjq

- Hits: 532

When tungsten carbide drill bits get dull, the easiest solution is usually to just replace them. But since tungsten carbide drill bits are relatively expensive tools, it may be worth a few minutes of your time to go ahead and sharpen the bit yourself. This is easily done by gently moving the ridges of the bit against a spinning grinding wheel. Because tungsten carbide is kind of material of high hardness, you will need to make sure you use a diamond-surface grinding wheel to affect the hard metal.

Instructions to sharpen a tungsten carbide drill bit:

I. Put on safety goggles and canvas gloves. The goggles protect your eyes from sparks and debris. The gloves protect against accidentally pushing your fingers against the wheel and against burning yourself if the bit gets hot.

II. Turn on your grinding wheel. Hold the side of the drill bit next to the broad side of the wheel, so the bit is parallel to it.

III. Holding the bottom of the tungsten carbide drill bit, press the side of the bit lightly against the side of the spinning wheel.

IV. Turn the bit clockwise while moving it downward on the wheel. Make sure the surface of the wheel is coming in contact with the cutting ridge of the blade. You will be able to distinguish the parts of the bit that have been sharpened by the brighter shine on the metal. If you feel the bit getting hot, lift it from the wheel until it cools.

V. After you have sharpened the ridges of the tungsten carbide drill bit, touch any angles at the tip to the wheel to smooth them out and sharpen the edges. Take care to press only the flat side of each angle to the wheel, and not the point.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Milling Cutter Selecting

- Details

- Category: Tungsten Information

- Published on Thursday, 23 October 2014 18:03

- Written by xjq

- Hits: 468

Tungsten carbide milling cutters are more expensive than high speed steel, but last longer, and can be run much faster, so prove more economical in the long run. Tungsten carbide milling cutter selecting is not a simple task. There are many variables, opinions and lore to consider, but essentially the machinist is trying to choose a tool which will cut the material to the required specification for the least cost. There are four main factors to consider when selecting a tungsten carbide milling cutter.

I. Diameter:

Larger tools can remove material faster than small ones, therefore the largest possible cutter that will fit in the job is usually chosen. When milling an internal contour, or concave external contours, the diameter is limited by the size of internal curves. The radius of the cutter must be less than or equal to the radius of the smallest arc.

II. Flutes:

More flutes allows a higher feed rate, because there is less material removed per flute. But because the core diameter increases, there is less room for swarf, so a balance must be chosen.

III. Coating:

Coatings, such as titanium nitride, also increase initial cost but reduce wear and increase tool life. TiAlN coating reduces sticking of aluminium to the tool, reducing and sometimes eliminating need for lubrication.

IV. Helix angle:

High helix angles are typically best for soft metals, and low helix angles for hard or tough metals.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Worm Gear Hob Introduction

- Details

- Category: Tungsten Information

- Published on Thursday, 23 October 2014 16:20

- Written by xjq

- Hits: 495

The tungsten carbide worm gear hob is typically used in turbine machining and its machining method is almost the same as that of the gear hob. What differentiates them is that during worm gear hob machining, the helix angle is not being moved while gear hob does. Because of this, when the worm gear hob with a large helix performs its machining, its clearance angle tends to be touched easily, making the machining become more difficult, so does its production.

The differences between tungsten carbide worm gear hob production and that of the gear hob are mainly as follows:

I. Reference circle requirements in worm gear hob production;

II. Tooth shape difference;

III. The helix angle is not being moved during worm gear hob machining, therefore, the axial pitch of worm gear hobs is just equal to that of gear hobs.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

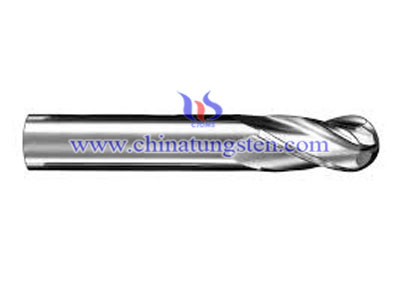

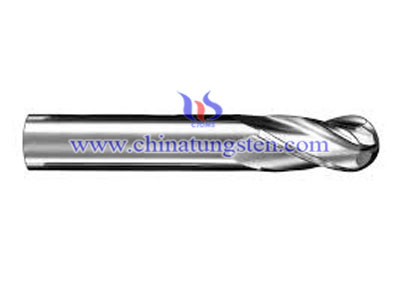

Tungsten Carbide Ball Nose Cutter Inroduction

- Details

- Category: Tungsten Information

- Published on Thursday, 23 October 2014 18:00

- Written by xjq

- Hits: 488

Tungsten carbide ball nose cutters or ball end mills are similar to slot drills, but the end of the cutters are hemispherical. They are ideal for machining 3-dimensional contoured shapes in machining centres, for example in moulds and dies. They are sometimes called ball mills in shop-floor slang, despite the fact that that term also has another meaning. They are also used to add a radius between perpendicular faces to reduce stress concentrations.

There is also a term bull nose cutter, which refers to a cutter having a corner radius that is fairly large, although less than the spherical radius (half the cutter diameter) of a ball mill; for example, a 20-mm diameter cutter with a 2-mm radius corner. This usage is analogous to the term bull nose center referring to lathe centerswith truncated cones; in both cases, the silhouette is essentially a rectangle with its corners truncated (by either a chamfer or radius Don).

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Choosing Tungsten Carbide Milling Tool Cutting Speed

- Details

- Category: Tungsten Information

- Published on Thursday, 23 October 2014 16:17

- Written by xjq

- Hits: 458

The choosing of tungsten carbide milling tool cutting speed is mainly based on the material type of the workpiece being processed while that of the rate of feeding is based not only on the material type of workpieces but also on the tool diameters. Cutting parameter lists may be attached to the cutter samples provided by some of the foreign cutter manufacturers for reference. However, the cutting parameter can also be affected by many other factors such as machine tools, cutter system, shapes of workpieces being processed, clamping pattern and so on, and therefore the cutting and feeding speed should be adjusted according to different practical situations. When the tool life is the first priority for consideration, the cutting and feeding speed then can be reduced to an appropriate extent, while if there is a poor chipping condition, the cutting speed can be increased to some extent.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com