Precautions for Using Cut-Resistant Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Monday, 17 March 2025 19:05

- Written by Zhenghua

- Hits: 291

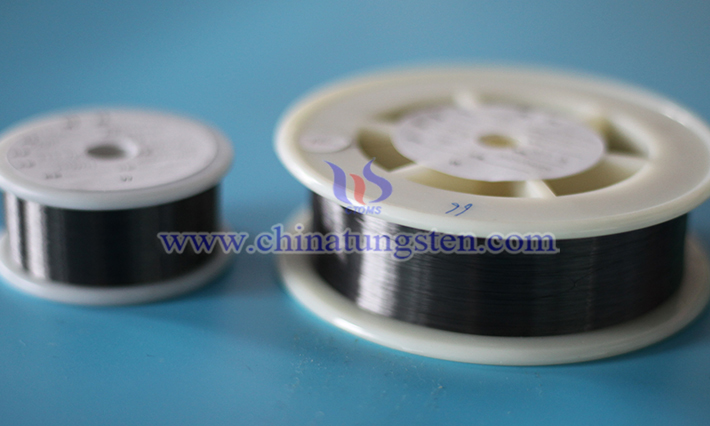

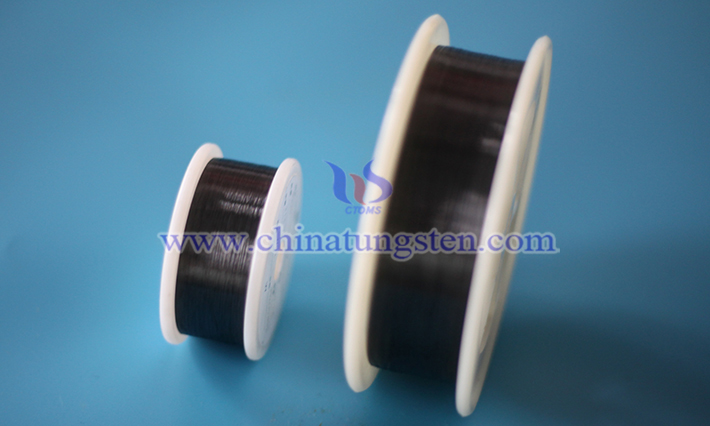

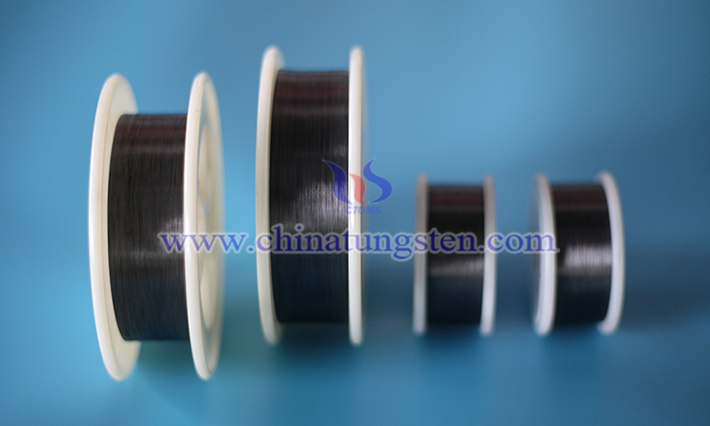

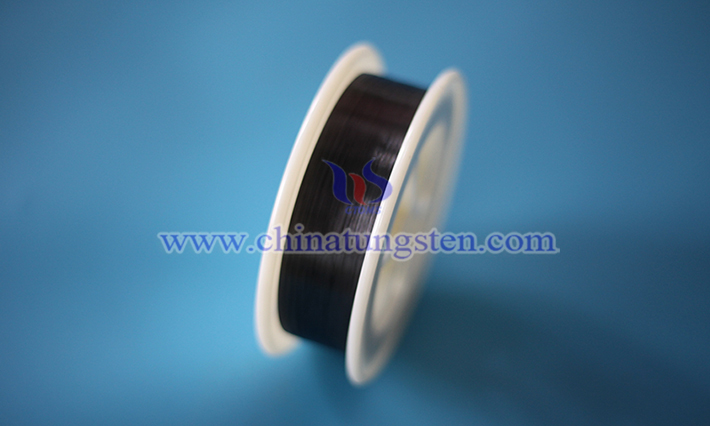

As a high-strength, high-melting-point industrial material, cut-resistant tungsten wire is widely used in fields such as electrical discharge machining (EDM), semiconductor manufacturing, and aerospace. To ensure safe and efficient use, the following precautions should be followed:

Read more: Precautions for Using Cut-Resistant Tungsten Wire

Application of Cut-Resistant Tungsten Wire in Optical Devices

- Details

- Category: Tungsten Information

- Published on Monday, 17 March 2025 19:03

- Written by Zhenghua

- Hits: 293

The high strength, hardness, melting point, and trend towards finer wire gauge of cut-resistant tungsten wire meet the requirements of the optical device field for precision, stability, and miniaturization development. Below are the main applications of cut-resistant tungsten wire in optical devices:

Read more: Application of Cut-Resistant Tungsten Wire in Optical Devices

Applications of Cut-Resistant Tungsten Wire in the Electronics and Information Industry

- Details

- Category: Tungsten Information

- Published on Monday, 17 March 2025 18:58

- Written by Zhenghua

- Hits: 306

Cut-resistant tungsten wire, with its high strength, heat resistance, wear resistance, and excellent conductivity, plays a vital role in the electronics and information industry, particularly in miniaturized and high-reliability scenarios. Below is a detailed analysis of its primary applications:

Read more: Applications of Cut-Resistant Tungsten Wire in the Electronics and Information Industry

Applications of Cut-Resistant Tungsten Wire in the Textile Industry

- Details

- Category: Tungsten Information

- Published on Monday, 17 March 2025 19:00

- Written by Zhenghua

- Hits: 303

Cut-resistant tungsten wire, with its high strength, wear resistance, and high-temperature tolerance, plays a significant role in specific scenarios within the textile industry. Below are the primary applications of cut-resistant tungsten wire in this field:

Read more: Applications of Cut-Resistant Tungsten Wire in the Textile Industry

Cut-Resistant Tungsten Wire in Electronic Information Field

- Details

- Category: Tungsten Information

- Published on Monday, 17 March 2025 18:55

- Written by Zhenghua

- Hits: 282

The application of cut-resistant tungsten wire in the field of electronic information is both extensive and significant, primarily due to tungsten's inherent properties such as high melting point, high density, excellent electrical and thermal conductivity, as well as superior mechanical strength and corrosion resistance. These characteristics enable tungsten wire to meet the demands of high precision and reliability in the electronic information industry, particularly in applications under extreme conditions. Below are the main applications of cut-resistant tungsten wire in this field:

Read more: Cut-Resistant Tungsten Wire in Electronic Information Field

sales@chinatungsten.com

sales@chinatungsten.com