Cut-Resistant Tungsten Wire for Stone Processing

- Details

- Category: Tungsten Information

- Published on Monday, 07 April 2025 18:42

- Written by Zhenghua

- Hits: 272

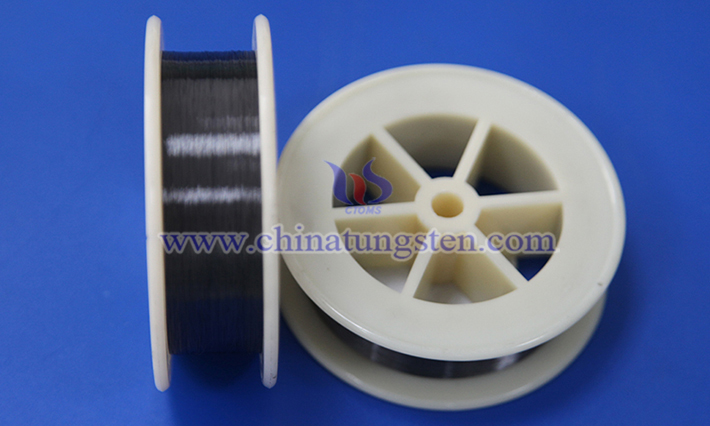

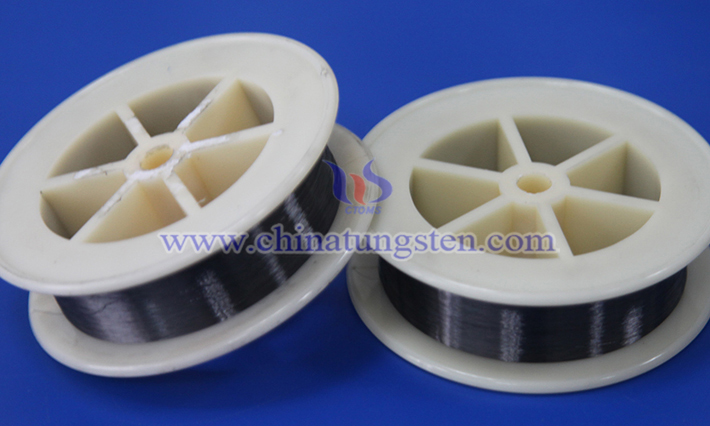

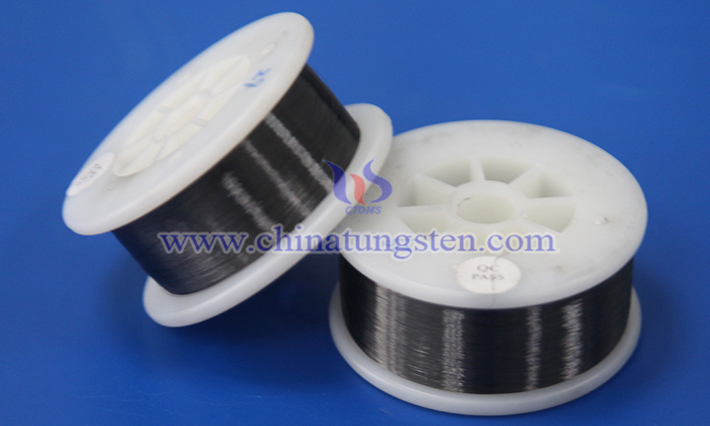

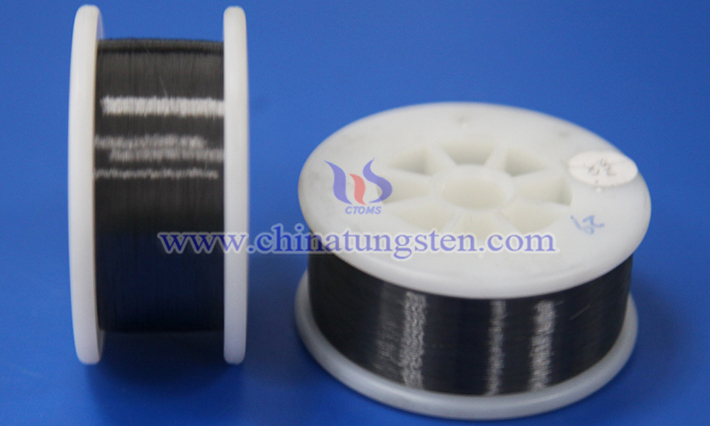

In the modern stone processing industry, efficient, precise, and durable cutting tools are crucial for improving production efficiency and product quality. With continuous technological advancements, cut-resistant tungsten wire has emerged as a high-performance material, gaining prominence in the field of stone processing. Renowned for its exceptional physical properties and chemical stability, tungsten wire has become an ideal choice for cutting hard stone materials. This article explores the characteristics, applications, and significance of cut-resistant tungsten wire in stone processing.

Cut-Resistant Tungsten Wire for Metal Cutting

- Details

- Category: Tungsten Information

- Published on Monday, 07 April 2025 18:39

- Written by Zhenghua

- Hits: 290

Cut-resistant tungsten wire is a key material in the metal cutting domain. It is widely applied due to its extremely high melting point (approximately 3422°C), exceptional tensile strength, and high-temperature stability, particularly excelling in processing tasks that demand precision and durability.

Tactical Gloves with Cut-Resistant Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Monday, 07 April 2025 18:35

- Written by Zhenghua

- Hits: 281

Tactical gloves, designed specifically for military, law enforcement, and outdoor activities, prioritize both protection and flexibility. In recent years, advancements in material science have introduced cut-resistant tungsten wire into the design of tactical gloves, bringing new possibilities to traditional protective capabilities.

Cut-Resistant Tungsten Wire for Glass Processing

- Details

- Category: Tungsten Information

- Published on Monday, 07 April 2025 18:37

- Written by Zhenghua

- Hits: 277

Tungsten (W) is a rare metal with an exceptionally high melting point and hardness. Its unique properties make it an ideal choice for high-precision and high-durability processing tasks. Cut-resistant tungsten wire is a fine, wire-like tool primarily made from tungsten metal. Due to its outstanding physical and chemical properties, it holds a significant position in the field of glass processing.

Stab-Proof Vests Using Cut-Resistant Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Monday, 07 April 2025 18:33

- Written by Zhenghua

- Hits: 291

Stab-proof vests, as a vital piece of personal protective equipment, are widely used by law enforcement officers, military personnel, security guards, and individuals in high-risk occupations. Their primary function is to defend against stabbing, slashing, and chopping attacks from sharp implements such as knives and daggers.

Read more: Stab-Proof Vests Using Cut-Resistant Tungsten Wire

sales@chinatungsten.com

sales@chinatungsten.com