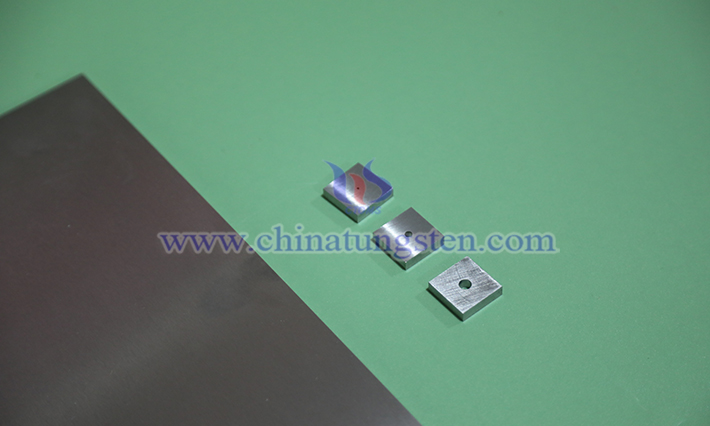

Tungsten-Copper Contact

- Details

- Category: Tungsten Information

- Published on Monday, 21 July 2025 17:14

- Written by Xiaoting

- Hits: 101

Like tungsten-silver (WAg) contacts, tungsten-copper (WCu) contacts are also a typical type of tungsten contact. Since both tungsten-silver and tungsten-copper contacts are products based on refractory metal tungsten, their physicochemical properties, production methods, and applications are fundamentally similar. It should be noted that the price of silver is generally higher than that of copper.

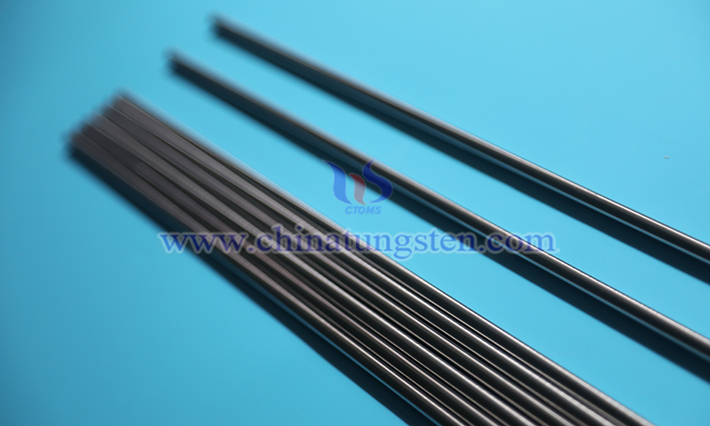

Tungsten Alloy Rod

- Details

- Category: Tungsten Information

- Published on Monday, 21 July 2025 17:12

- Written by Xiaoting

- Hits: 94

Depending on their shapes, tungsten-based alloys can be categorized into tungsten alloy rods, tungsten alloy blocks, tungsten alloy plates, and tungsten alloy spheres. While their physicochemical properties are generally similar, their applications differ.

Applications of Tungsten-Nickel-Iron Alloy in the Medical Field

- Details

- Category: Tungsten Information

- Published on Thursday, 17 July 2025 15:16

- Written by Xiaoting

- Hits: 101

The applications of tungsten-nickel-iron alloy as a shielding material in the medical field stems from its unique physical properties, such as high density, good chemical stability, and excellent radiation shielding capabilities. With a density typically ranging from 16.5 to 18.75 g/cm³, its ability to attenuate X-rays, γ-rays, and other radiation is comparable to traditional lead shielding materials. Moreover, it is less prone to fracturing or deforming due to impacts or vibrations, giving it a clear advantage in medical radiation protection scenarios.

Read more: Applications of Tungsten-Nickel-Iron Alloy in the Medical Field

Applications of Tungsten-Nickel-Iron Alloy in Welding Electrodes

- Details

- Category: Tungsten Information

- Published on Thursday, 17 July 2025 15:19

- Written by Xiaoting

- Hits: 107

Tungsten-nickel-iron alloy, with its unique physical and mechanical properties, demonstrates significant applications value in the field of welding electrodes. When used to manufacture welding electrodes, the high tungsten content (typically over 90%) is the core source of its advantages. Tungsten’s melting point, as high as 3422°C, far exceeds that of most metal materials, enabling the electrode to maintain a stable form in the high-temperature arc environment and preventing excessive wear due to melting. This is crucial for ensuring the continuity of the welding process. The addition of nickel and iron effectively mitigates the brittleness of pure tungsten, providing the electrode with a certain degree of plasticity and toughness, making it less prone to cracking during processing, installation, and use, while also enhancing its electrical conductivity to ensure stable arc generation and energy transfer.

Read more: Applications of Tungsten-Nickel-Iron Alloy in Welding Electrodes

Impact of Carbon on the Hardness of Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

- Published on Thursday, 17 July 2025 15:13

- Written by Xiaoting

- Hits: 95

Carbon plays a critical role in regulating the microstructure and mechanical properties of tungsten-nickel-iron alloys, with its influence on alloy hardness primarily achieved through altering the microstructure, forming carbides, and modulating interface bonding states.

Read more: Impact of Carbon on the Hardness of Tungsten-Nickel-Iron Alloy

sales@chinatungsten.com

sales@chinatungsten.com