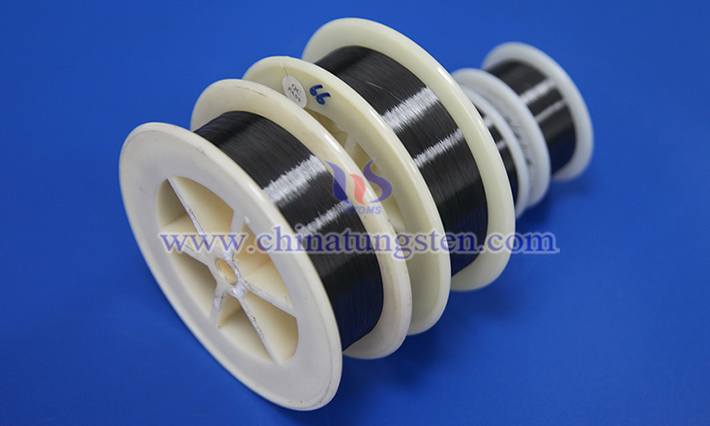

Cut-Resistant Tungsten Wire: A Sharp Blade in High Temperature Environments

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 April 2025 19:54

Cut-resistant tungsten wire is becoming a benchmark material for cutting tasks in extreme environments with its excellent high temperature performance and continuous technological innovation.

1. Material Properties: Why Choose Tungsten?

Ultra-High Melting Point: The melting point of tungsten is as high as 3422°C, which allows it to maintain structural stability in high temperature environments.

Hardness and Wear Resistance: The body-centered cubic crystal structure gives tungsten high hardness and wear resistance, especially better than most metals at high temperatures.

Low Thermal Expansion Coefficient: Dimensional stability in high temperature environment, ensuring cutting accuracy and reducing the impact of thermal deformation.

2. Key Technologies for High Temperature and Oxidation Resistance

Alloying Treatment: Add rhenium (Re) or molybdenum (Mo) to improve toughness and reduce high temperature brittleness.

Surface Coating Technology:

Tungsten carbide (WC): Improve surface hardness and oxidation resistance, suitable for extreme temperatures.

Ceramic coating (such as Al₂O₃): Enhance corrosion resistance and extend tool life.

3. Manufacturing Process: From Powder to Precision Wire

Powder Metallurgy: High-purity tungsten powder is pressed and sintered into billets to control grain size.

Wire Drawing: Drawing to micron diameter in succession, annealing to eliminate stress, and balance strength and toughness.

Post-Processing: CVD/PVD coating deposition to optimize surface properties.

4. Application Scenarios: Core Tool for High Temperature Cutting

Aerospace: Cutting nickel-based high-temperature alloys (such as Inconel) and titanium alloy parts.

Electronics Industry: Precision cutting of silicon wafers and ceramic substrates, suitable for laser-assisted processing.

Automotive Manufacturing: Processing high-strength steel and composite materials to improve production efficiency.

Energy Field: Maintenance of nuclear reactor components and cutting of high-temperature pipelines.

5. Performance Advantage Comparison

vs Ceramic Tools: Cut-resistant tungsten wire has better thermal shock resistance, is not easy to break, and is suitable for dynamic loads.

vs Hard Alloys: Higher hardness retention rate under high temperature environment (e.g. HV is still above 800 at 1000°C).

Cost-Effectiveness: Although the initial cost is high, the extended life reduces the replacement frequency, which is suitable for high value-added industries.

6. Challenges and Solutions

Oxidation Protection: Multi-layer gradient coating (such as TiAlN/WC) delays the formation of oxide layer.

Brittleness Problem: Research and development of nanocrystalline tungsten wire (grain size <100nm) improves toughness.

Cost Control: Recycling of waste materials and optimization of wire drawing process reduce production costs.

7. Innovation Frontiers and Future Trends

Nanocomposite Coating: Graphene-enhanced coating improves thermal conductivity and reduces thermal stress.

Intelligent Sensor Integration: Real-time monitoring of the wear state of cut-resistant tungsten wire to achieve predictive maintenance.

3D Printed Tungsten Wire Structure: Customized mesh tool for complex geometry cutting.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com